You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RRussellTx - 1974 Commando 850 Project

- Thread starter RussellTx

- Start date

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,072

Some info from Wassell: T J Wassell Limited is a separate company. They are located in Cannock run by Tim Wassell one of the original owner's sons.I can't answer that, possibly no connection to W E Wassell, I don't know.

T J Wassell Engineering Ltd in Unit 2 A & J Business Park, New Road, Burntwood, Staffordshire, WS7 0BT

Details for T J Wassell Engineering Ltd in Unit 2 A & J Business Park, New Road, Burntwood, Staffordshire, WS7 0BTdirectory.gloucestershirelive.co.uk

TJ Wassell | Old Bike Mart

Keen to discover whether the heart of England’s motorcycle industry still has plenty to offer, Dave Manning heads to the West Midlands, and finds lots of tr ...www.oldbikemart.co.uk

Their web site is: https://oldboystoys.shop/ They list many things they make but you have to email them to get actual info.

RussellTx

VIP MEMBER

- Joined

- Jul 28, 2024

- Messages

- 60

Thanks!Some info from Wassell: T J Wassell Limited is a separate company. They are located in Cannock run by Tim Wassell one of the original owner's sons.

Their web site is: https://oldboystoys.shop/ They list many things they make but you have to email them to get actual info.

Sounds legit so I went ahead and ordered a set to see what they look like. They are a very reasonable price given the work/risk involved in patching mine up.

johnm

VIP MEMBER

- Joined

- Feb 26, 2008

- Messages

- 1,836

Might be a bit late but I'd carefully measure and send details - maybe photos of exactly what your balanced pipe details are. Assuming you ordered balanced pipe headers not standard ones.Thanks!

Sounds legit so I went ahead and ordered a set to see what they look like. They are a very reasonable price given the work/risk involved in patching mine up.

The reason I say this is way back when I got a set of balance pipe Mk2 headers for my bike from British spares who were at that time in Wellington they didn't fit. And when I went in to visit with my old original headers they said they were Mk3 headers. At that time British spares were one of the biggest suppliers in the world and had all the options to compare.

My Mk2 was built late in the production run in August 1974 so maybe by then they were fitting a Mk3 type. Yours is earlier in Feb 74 so maybe???

Perhaps there is someone on here with better info (LAB ?) because 25 years latter I don't remember the details. But I do remember the first ones didn't fit and I do see RGM list both Mk2 and Mk3 balanced pipe headers so something is different.

Last edited:

johnm

VIP MEMBER

- Joined

- Feb 26, 2008

- Messages

- 1,836

Been thinking about your project and I think it might be worth it to list the dumb and useful things I found when I refurbished my Mk2 about 5 years ago. A bit of background. I'm 70 now and bought my bike back in 1978 when I was at uni. For 5 or six years it was my only transport and was usable but very rough because I was a broke grad student. Then I moved overseas several times. The bike got used on and off but finally when I retired I gave it a huge birthday present. I went overboard and bought it lots of expensive upgrades which are practically more than are really needed. Except for those of us with bone on bone knee issues.

So anyway this is what I found that you might wish to consider. I already recomended Norman Whites book and recomend careful consideration of his procedures.

My experience

Frame suspension and overall handling.

Commandos have lots of potential for bad handling with various spacers and misalignments and especially the isolastics. Mine was always a bad headshaker and pulled hard to the left if my hands were off the bars. There is a paper written years ago called the World's straightest Commando. It's a bit hard to follow in places but worth reading. I can't seem to copy the link but it's easy to search online.

My bike was much improved after following the paper. Critical steps include checking the frame is straight, that the front rim is exactly midway between the fork stantions. (Many are not), facing off the isotastic tubes so the clearance is even all the way around, checking the rear rim is centre down the frame tube, checking the chain runs are straight - most are not - most importantly checking the swinging arm is not bent. 9 out of ten are twisted. Mine certainly was.

If you get this correct your well on the way to a nice handling bike. Front forks are often bent. Both the stantions and the yokes or triple clamps. The triple clamps can be straightened using a granite plate. Fit the stantions and carefully measure for parallel and straightness. Use an old stantion to lever the triple clamps straight if necessary. It can take several attempts.

Plenty of upgrades available for the front suspension from cheaper JS motorsport through medium expensive, Lansdowne internals from Don Pender up to twice the original price of the bike at Maxton.

Rear shocks are also modest to super expensive in pricing. JSmotorsport has what looks like an interesting option with an Ikon shock with a longer movement. I'd look at that if I needed a replacement. Be careful when buying shocks because the Commando needs more clearance for the rear chainguard than most bikes.

Swinging arm. The design was changed alot. You probably have frost plugs fitted with what looks like a grease nipple on the timing side. Do not use grease. These bikes use 140 weight oil and a good upgrade is to drill a hole in the top of the swinging arm tube and fit a nipple with a thin plastic pipe running up behind the battery. Then you can refill the pipe once a year to keep the oil topped up. The swinging arm is the only thing on my bike that leaks. Which is a bit frustrating. There are clamps for the spindle sold by a few places. I think New York Norton among others.

Rear axle. These snap at the dummy axle. Andover Norton say they don't but I have seen at least 5 snapped. Not on my bike but I changed mine to a one piece anyway. Don Pender sells these.

I havnt talked upbout upgraded isolastics. You can instal the Mk111 vernier type. Again lots of places sell them so you can decide. I'd definitely upgrade the top mount under the tank. Again a few options. I use the Dave Taylor upgrade.

Brakes and wheels.

I already said to centre the rims. You might need to check the bearings after all these years.

Front disc brake. The original was very wooden and weak. I would at least do the Andover Norton front mastercylinder upgrade. I have read lots of reports on the resized sleeved options. Some people love them installed 30 years, other people have reported total failures. I like a brake that works 100 % always and forever so I'd spend the money with Andover. A braided upgraded hydraulic line might be good too. Talking about braided lines be supercareful to either keep them securely away from metal parts or get plastic coated ones. Those braided lines are like a mini hacksaw. Also very very true for any braided oil lines you may try. Especially the oil line up to the rocker. Use only plastic covered braided ones unless you want a hole hacksaw in your gas tank. CNW sell a very nice one. People should be able to advise on good modern brake pads.

I went overboard and bought a CNW Brembo front brake upgrade but unless your rich I'd consider the Andover option.

Rear brake. This brake can be a bit weak as standard too but RGM sell a high performance set of shoes and they really do work. You may have to arc the shoes on a lath but boy they are way better than the standard shoes.

Don't be tempted to keep your old shoes and linings. After years in storage the linings can detach from the shoes. I have personally had this happen. In fact I now add a few rivets to any brake shoes I buy.

Another unpleasant little trick with the rear brake is that there were a bunch of rear brake cables sold where the inner cable pulled through the nipple. Had this happen to me too. So when you get a new cable carefully check you can see wire strands bent and properly secured into the nipples. Friends and I cut and resolder our brake, clutch and throttle nipples because of about 200 years of nasty experiences but unless you really know what you are doing I'd buy only from name vendors and check them visually.

Important. If the rear brake cable breaks the brake lever can swing down and dig into the ground throwing you off. There is an after market spring you can fit to the pedal to stop this happening. A very good investment.

OK. Had to split this post so it continues below

So anyway this is what I found that you might wish to consider. I already recomended Norman Whites book and recomend careful consideration of his procedures.

My experience

Frame suspension and overall handling.

Commandos have lots of potential for bad handling with various spacers and misalignments and especially the isolastics. Mine was always a bad headshaker and pulled hard to the left if my hands were off the bars. There is a paper written years ago called the World's straightest Commando. It's a bit hard to follow in places but worth reading. I can't seem to copy the link but it's easy to search online.

My bike was much improved after following the paper. Critical steps include checking the frame is straight, that the front rim is exactly midway between the fork stantions. (Many are not), facing off the isotastic tubes so the clearance is even all the way around, checking the rear rim is centre down the frame tube, checking the chain runs are straight - most are not - most importantly checking the swinging arm is not bent. 9 out of ten are twisted. Mine certainly was.

If you get this correct your well on the way to a nice handling bike. Front forks are often bent. Both the stantions and the yokes or triple clamps. The triple clamps can be straightened using a granite plate. Fit the stantions and carefully measure for parallel and straightness. Use an old stantion to lever the triple clamps straight if necessary. It can take several attempts.

Plenty of upgrades available for the front suspension from cheaper JS motorsport through medium expensive, Lansdowne internals from Don Pender up to twice the original price of the bike at Maxton.

Rear shocks are also modest to super expensive in pricing. JSmotorsport has what looks like an interesting option with an Ikon shock with a longer movement. I'd look at that if I needed a replacement. Be careful when buying shocks because the Commando needs more clearance for the rear chainguard than most bikes.

Swinging arm. The design was changed alot. You probably have frost plugs fitted with what looks like a grease nipple on the timing side. Do not use grease. These bikes use 140 weight oil and a good upgrade is to drill a hole in the top of the swinging arm tube and fit a nipple with a thin plastic pipe running up behind the battery. Then you can refill the pipe once a year to keep the oil topped up. The swinging arm is the only thing on my bike that leaks. Which is a bit frustrating. There are clamps for the spindle sold by a few places. I think New York Norton among others.

Rear axle. These snap at the dummy axle. Andover Norton say they don't but I have seen at least 5 snapped. Not on my bike but I changed mine to a one piece anyway. Don Pender sells these.

I havnt talked upbout upgraded isolastics. You can instal the Mk111 vernier type. Again lots of places sell them so you can decide. I'd definitely upgrade the top mount under the tank. Again a few options. I use the Dave Taylor upgrade.

Brakes and wheels.

I already said to centre the rims. You might need to check the bearings after all these years.

Front disc brake. The original was very wooden and weak. I would at least do the Andover Norton front mastercylinder upgrade. I have read lots of reports on the resized sleeved options. Some people love them installed 30 years, other people have reported total failures. I like a brake that works 100 % always and forever so I'd spend the money with Andover. A braided upgraded hydraulic line might be good too. Talking about braided lines be supercareful to either keep them securely away from metal parts or get plastic coated ones. Those braided lines are like a mini hacksaw. Also very very true for any braided oil lines you may try. Especially the oil line up to the rocker. Use only plastic covered braided ones unless you want a hole hacksaw in your gas tank. CNW sell a very nice one. People should be able to advise on good modern brake pads.

I went overboard and bought a CNW Brembo front brake upgrade but unless your rich I'd consider the Andover option.

Rear brake. This brake can be a bit weak as standard too but RGM sell a high performance set of shoes and they really do work. You may have to arc the shoes on a lath but boy they are way better than the standard shoes.

Don't be tempted to keep your old shoes and linings. After years in storage the linings can detach from the shoes. I have personally had this happen. In fact I now add a few rivets to any brake shoes I buy.

Another unpleasant little trick with the rear brake is that there were a bunch of rear brake cables sold where the inner cable pulled through the nipple. Had this happen to me too. So when you get a new cable carefully check you can see wire strands bent and properly secured into the nipples. Friends and I cut and resolder our brake, clutch and throttle nipples because of about 200 years of nasty experiences but unless you really know what you are doing I'd buy only from name vendors and check them visually.

Important. If the rear brake cable breaks the brake lever can swing down and dig into the ground throwing you off. There is an after market spring you can fit to the pedal to stop this happening. A very good investment.

OK. Had to split this post so it continues below

Last edited:

johnm

VIP MEMBER

- Joined

- Feb 26, 2008

- Messages

- 1,836

Electrics

Not my strongest suit but also not Nortons strong area either. After all these years most of the electrical bullet connectors and switches will be corroded and have high resistance. Buy a multimeter.

Then decide if your going to work with what you have or replace. If your going with what you have check every single connection with the multimeter. The five way connector under the tank is usually a disaster. Note the riveted earth connector inside the headlight shell. They are often loose and the rivet will need compressing or replacing. Beleive it or not the earth return on the indicators is via the chrome on the plastic into the headlight shell. Many people add a real earth return to the indicators.

If replace I have to report not great things about the new looms. I got one and immediately found a crimped nipple that fell off in my hands. Wonderful.

So many people make their own. Grant Tiller on this site has clear wiring diagrams which cover options for different electronic ignitions rectifiers etc.

If you want to keep the bullet connector style look Andover sell the original bullet size options which are a different diameter to the ones you will find down the local shop. Plus the original Lucas colour wires which is nice.

Use dielectric grease at the connectors. Check very carefully the coil wire connection.

I'm not a fan of the original Norton handle bar switches. I find the long paddle type levers clumsy. So I switched to a Triumph option with indicators and high beam dip all on the left side. The original kill button - not a switch- is a bit famous for killing the ignition whether you want it to or not. So always a good place to check if the bike doesn't start. As I said on an earlier post upgrading to electronic ignition is done by 95% of owners. Several options. I'd chose the one your nearest reliable dealer supplies.

What else? The main switches corrode internally. The modern replacements are generally not as good as the original lucas so try cleaning it up and resoldering if you can. Don't hang too many keys on the key ring because the weight will wear out the switch. Replace the glass fuse with a modern blade fuse. Read up about the British fuses being rated blow versus continuous use. I don't feel qualified to recomend but I know it's a thing so get one of the local US guys to explain. If your keeping the old zenor diode option located down behind the timing side z plate then do not short the feed wire to the frame. It's always live and you may blow fuses and destoy your ignition black box. Been there done that.

The alternator rotor clearance is an area with lots of potential issues. Check the rotor carefully because they can breakup. Be certain to fit as as per the book and check clearance at several points and rotations of the crankshaft. The wires get very brittle inside the chain case with the heat and oil. Check carefully including at the exit through the back. Wires are commonly broken.

Motor and gearbox.

The layshaft bearing has already been mentioned. Norman White covers it in his book.

Also have a very careful check of the kick-start pall. Again Norman White goes through this. Problems are common here. There were bad aftermarket pins around at one time. This pin should be replaced as a maintenance item but get the right one from Andover or a reliable supplier. There's a correct mark it should have and I have forgotten it sorry. But someone should know.

Your bike has very few miles so the gears are probably good. But note the second gear pair are different in a Mk2 and should not be mixed with earlier second gears. You can replace with a pair but not mix the pairs up.

The seal upgrades on the outcover are really great. I recommend them. Also the RGM foldaway style kick-start lever is great. The original stuck in the back of my calf for years. New York Norton sells them I think.

Engine.

This is going depend a lot on what you find when you get it apart but there are a few potential nasty surprises that need checking.

First off. Your main bearings should be good but if in doubt again replace with the correct bearings from a known supplier. Here I would definitely go Andover. There are small novels written about Norton mainbearing and lots and lots of miss information. I'd just go Andover. The more recent bearings they supply are stamped made in India but they are the current recomended ones.

Lots of camshaft options and people have lots of opinions. I just use the standard 850 camshaft. If you change the camshaft have the followers refaced. Don't use worn faces on a new camshaft. Very important to make sure you pour an egg cup or two of oil down the push rod tunnels before the first engine start. You can kill a camshaft in the first 10 seconds if they are dry. If you do anything exotic with camshaft you are going to have to check full operation in the lifters and also valve to piston clearance using plasticine and also valve spring coil bind clearance and pressure over the nose of the cam.

Not going to say anything about pistons. Options available and follow the advice of the vendor and manuals and Norman White for installation

Crankshaft.

Cross your fingers and hope you get lucky. Norton did a disgraceful job in machining the drive side shaft to crank porkchop change of section. It is a sharp right angle and many many many crankshafts are cracked and broken here. I have corresponded with Andover about this and they say they don't see many. Well in that case Norton must have sent them all to NZ because I have seen lots. Including my own. Andover did say however that the Norton production racers used to break cranks there until they machined a radius in.

You must have the crank crack tested. If it's good seriously consider having an undercut radius machined and polished into this change of section. There is a thread on here somewhere which describes this with drawing. Jim at JSmotorsports know about this in the USA.

Note I'm not talking about a potential sharp angle if the big ends have been badly reground. This is another problem. If you have to regrind your big ends then you MUST use an proper experienced engineer who will dress the stone to leave a proper radius as defined in the workshop manual. This radius must be smooth and polished otherwise the crank will break.

The third crank issue is mismatched drilling for the oil feed in the drive side. If you look down inside the drive side crank you can see two drillings for the oil feed. One is plugged off after drilling from the drive side. These can be mismatched and give a stress riser which breaks the crank at the drive side end of the drive side big end. These drillings can be smoothed out by a good engineer

So three things to check to make your crank safe. Don't go revving above 6800 rpm too often you will explode the fly wheel. If you want to play games then check out Andy Molnars super expensive crank options. Be prepared to sell your children.

There's a seal upgrade on the tach drive which is very good. They always leak so I recomend it.

I use threebond Yambind or similar for the gaskets.

Also very important. Upgrade your breather using the JS motorsport reedvalve breather. If yiu do this and use the right gasket cement and carefully assembly your motor and gearbox will not leak.

I'm not very good with the clutch side. Over the years I tried several options with varying degrees of success. Nowadays I have a CNW electric start so belt drive and dry clutch so all the issues have gone away. The seal that goes on the end of the gearbox mainshaft that keeps the oil from coming down the clutch push rod tunnel is a good upgrade. Originally designed by Dyno Dave on this site I think it's marketed by CNW and New York Norton?

OK. I have probably forgotten lots and I wrote this in my phone so will have to probably come back and correct a few times but this is enough for the moment.

Good luck with that bike.

Not my strongest suit but also not Nortons strong area either. After all these years most of the electrical bullet connectors and switches will be corroded and have high resistance. Buy a multimeter.

Then decide if your going to work with what you have or replace. If your going with what you have check every single connection with the multimeter. The five way connector under the tank is usually a disaster. Note the riveted earth connector inside the headlight shell. They are often loose and the rivet will need compressing or replacing. Beleive it or not the earth return on the indicators is via the chrome on the plastic into the headlight shell. Many people add a real earth return to the indicators.

If replace I have to report not great things about the new looms. I got one and immediately found a crimped nipple that fell off in my hands. Wonderful.

So many people make their own. Grant Tiller on this site has clear wiring diagrams which cover options for different electronic ignitions rectifiers etc.

If you want to keep the bullet connector style look Andover sell the original bullet size options which are a different diameter to the ones you will find down the local shop. Plus the original Lucas colour wires which is nice.

Use dielectric grease at the connectors. Check very carefully the coil wire connection.

I'm not a fan of the original Norton handle bar switches. I find the long paddle type levers clumsy. So I switched to a Triumph option with indicators and high beam dip all on the left side. The original kill button - not a switch- is a bit famous for killing the ignition whether you want it to or not. So always a good place to check if the bike doesn't start. As I said on an earlier post upgrading to electronic ignition is done by 95% of owners. Several options. I'd chose the one your nearest reliable dealer supplies.

What else? The main switches corrode internally. The modern replacements are generally not as good as the original lucas so try cleaning it up and resoldering if you can. Don't hang too many keys on the key ring because the weight will wear out the switch. Replace the glass fuse with a modern blade fuse. Read up about the British fuses being rated blow versus continuous use. I don't feel qualified to recomend but I know it's a thing so get one of the local US guys to explain. If your keeping the old zenor diode option located down behind the timing side z plate then do not short the feed wire to the frame. It's always live and you may blow fuses and destoy your ignition black box. Been there done that.

The alternator rotor clearance is an area with lots of potential issues. Check the rotor carefully because they can breakup. Be certain to fit as as per the book and check clearance at several points and rotations of the crankshaft. The wires get very brittle inside the chain case with the heat and oil. Check carefully including at the exit through the back. Wires are commonly broken.

Motor and gearbox.

The layshaft bearing has already been mentioned. Norman White covers it in his book.

Also have a very careful check of the kick-start pall. Again Norman White goes through this. Problems are common here. There were bad aftermarket pins around at one time. This pin should be replaced as a maintenance item but get the right one from Andover or a reliable supplier. There's a correct mark it should have and I have forgotten it sorry. But someone should know.

Your bike has very few miles so the gears are probably good. But note the second gear pair are different in a Mk2 and should not be mixed with earlier second gears. You can replace with a pair but not mix the pairs up.

The seal upgrades on the outcover are really great. I recommend them. Also the RGM foldaway style kick-start lever is great. The original stuck in the back of my calf for years. New York Norton sells them I think.

Engine.

This is going depend a lot on what you find when you get it apart but there are a few potential nasty surprises that need checking.

First off. Your main bearings should be good but if in doubt again replace with the correct bearings from a known supplier. Here I would definitely go Andover. There are small novels written about Norton mainbearing and lots and lots of miss information. I'd just go Andover. The more recent bearings they supply are stamped made in India but they are the current recomended ones.

Lots of camshaft options and people have lots of opinions. I just use the standard 850 camshaft. If you change the camshaft have the followers refaced. Don't use worn faces on a new camshaft. Very important to make sure you pour an egg cup or two of oil down the push rod tunnels before the first engine start. You can kill a camshaft in the first 10 seconds if they are dry. If you do anything exotic with camshaft you are going to have to check full operation in the lifters and also valve to piston clearance using plasticine and also valve spring coil bind clearance and pressure over the nose of the cam.

Not going to say anything about pistons. Options available and follow the advice of the vendor and manuals and Norman White for installation

Crankshaft.

Cross your fingers and hope you get lucky. Norton did a disgraceful job in machining the drive side shaft to crank porkchop change of section. It is a sharp right angle and many many many crankshafts are cracked and broken here. I have corresponded with Andover about this and they say they don't see many. Well in that case Norton must have sent them all to NZ because I have seen lots. Including my own. Andover did say however that the Norton production racers used to break cranks there until they machined a radius in.

You must have the crank crack tested. If it's good seriously consider having an undercut radius machined and polished into this change of section. There is a thread on here somewhere which describes this with drawing. Jim at JSmotorsports know about this in the USA.

Note I'm not talking about a potential sharp angle if the big ends have been badly reground. This is another problem. If you have to regrind your big ends then you MUST use an proper experienced engineer who will dress the stone to leave a proper radius as defined in the workshop manual. This radius must be smooth and polished otherwise the crank will break.

The third crank issue is mismatched drilling for the oil feed in the drive side. If you look down inside the drive side crank you can see two drillings for the oil feed. One is plugged off after drilling from the drive side. These can be mismatched and give a stress riser which breaks the crank at the drive side end of the drive side big end. These drillings can be smoothed out by a good engineer

So three things to check to make your crank safe. Don't go revving above 6800 rpm too often you will explode the fly wheel. If you want to play games then check out Andy Molnars super expensive crank options. Be prepared to sell your children.

There's a seal upgrade on the tach drive which is very good. They always leak so I recomend it.

I use threebond Yambind or similar for the gaskets.

Also very important. Upgrade your breather using the JS motorsport reedvalve breather. If yiu do this and use the right gasket cement and carefully assembly your motor and gearbox will not leak.

I'm not very good with the clutch side. Over the years I tried several options with varying degrees of success. Nowadays I have a CNW electric start so belt drive and dry clutch so all the issues have gone away. The seal that goes on the end of the gearbox mainshaft that keeps the oil from coming down the clutch push rod tunnel is a good upgrade. Originally designed by Dyno Dave on this site I think it's marketed by CNW and New York Norton?

OK. I have probably forgotten lots and I wrote this in my phone so will have to probably come back and correct a few times but this is enough for the moment.

Good luck with that bike.

Last edited:

concours

VIP MEMBER

- Joined

- Dec 29, 2011

- Messages

- 9,572

Replacement balanced pipes are readily available. I've had great service from Feked. I'm running their pipes now, for 10,000 miles.Got stuck needing a thin box end spanner to get the head bolts from the bottom side of the barrel so I switched gears to try out the WD40 and 0000 steel wool on the holy header. Figured I could not hurt it too much more.

Really surprised how well these cleaned up! The other side is also shown for comparison of how dirty they were.

How common is rust holes on the bottom of the exhaust headers? Might be an option to just call them drain holes.

We'll see what the rest of the tear down says.

Off to shop for more tools again...

Exhausts :: Norton :: Exhaust Pipes :: 850cc :: Norton Commando 850cc MK2A Exhaust Pipes Set with Balance

Set of two exhaust pipes and the three section balance pipe required to fit a MKIIA / MK2A Norton Commando. OEM: 06-3397, 06-3398, 06-6332, 06-3991

However, this is a good fork in the road. Changing over to NON balanced pipes is one change I am so glad I did.

JMWO

Best I can see is, the exhaust threads being a problem area, is the result of multiple engineering EVOLUTION compromises. In the beginning, the head was cast iron and the threaded attachments probably worked just fine. Then the thread (head) material changed to softer aluminum... and they probably still worked OK. Then the Commando with Isolastic engine mounting system introduced lots of motion. And the four foot long pipe with a muffler hung on the end was hard to move from one end, overstressing the threaded joint. Then, in '74, the crossover pipe was added, requiring a shorter nut to...

- concours

- Replies: 155

- Forum: Norton Commando Forum

Last edited:

RussellTx

VIP MEMBER

- Joined

- Jul 28, 2024

- Messages

- 60

Thanks for the great info!OK. Turns out my message was too long so I had to cut and paste on my phone. Hope it worked

I’m going to print this out and put it with my manuals for reference.

RussellTx

VIP MEMBER

- Joined

- Jul 28, 2024

- Messages

- 60

Day 4 of the soak and still no movement.

I'm in no hurry...

I did receive some tools late today and I was able to remove the clutch and verify that the gearbox and rear wheel are turning fine.

The issue is definitely in the engine. Not shocked, but good to narrow it down for sure.

Also, thanks for helping me spend my money! I have been listening.

I have several buddies coming to visit tomorrow to check out the build so I stocked the fridge and spent some time getting the cobra cleaned up.

Not relevant to the build but it's a slow day and I wanted to provide some kind of update.

I'm in no hurry...

I did receive some tools late today and I was able to remove the clutch and verify that the gearbox and rear wheel are turning fine.

The issue is definitely in the engine. Not shocked, but good to narrow it down for sure.

Also, thanks for helping me spend my money! I have been listening.

I have several buddies coming to visit tomorrow to check out the build so I stocked the fridge and spent some time getting the cobra cleaned up.

Not relevant to the build but it's a slow day and I wanted to provide some kind of update.

- Joined

- May 7, 2005

- Messages

- 7,237

I bought the MK3 RGM for my MK2a, compared them to the rusty old ones I took off a decade ago and replaced with unbalanced ones at the time and the RGM MK3 matched the old rusty ones. They were probably also MK3 as they had the ends to suit the spherical inserts. Only difference to the unbalanced ones, other than the balance pipe being missing, is the MK3 pipes clear the primary case more. Which is not surprising with the MK3 having the extended crank and starter kit.I do see RGM list both Mk2 and Mk3 balanced pipe headers so something is different.

- Joined

- Apr 22, 2020

- Messages

- 3,234

Your lucky I don't live anywhere near you. I'd be pushing building a hot rodded up Norton.

For example, you could build a healthy engine while waiting for those pistons to free up. Molnar (TGA.co.uk) has cases, barrels, and a quality crank. JS Motorsport has some nice rods and pistons as well as valve train parts. AN has bearings and chains and other small necessary parts. If that head is junk, talk to Matt at cNw about an STS head. You could also think about a belt clutch. Oops there goes that $10K budget I mentioned, and you'd still need buffing compound, and probably wheels, brakes and the list goes on.

Save the soaking numbers matching cases for the next victim of Nortonitis.

That said you could also do it all stock, but the Cobra would be teasing the Norton about being so vanilla.

Watch out for that Woodinville Bourbon. It's smooth.

I agree with johnm about keeping the revs down once you get whatever version of Norton you decide on put together. Unfortunately, if you build an engine like I am suggesting you will have a hard time not pushing the engine once in a while. Resistance is futile.

For example, you could build a healthy engine while waiting for those pistons to free up. Molnar (TGA.co.uk) has cases, barrels, and a quality crank. JS Motorsport has some nice rods and pistons as well as valve train parts. AN has bearings and chains and other small necessary parts. If that head is junk, talk to Matt at cNw about an STS head. You could also think about a belt clutch. Oops there goes that $10K budget I mentioned, and you'd still need buffing compound, and probably wheels, brakes and the list goes on.

Save the soaking numbers matching cases for the next victim of Nortonitis.

That said you could also do it all stock, but the Cobra would be teasing the Norton about being so vanilla.

Watch out for that Woodinville Bourbon. It's smooth.

I agree with johnm about keeping the revs down once you get whatever version of Norton you decide on put together. Unfortunately, if you build an engine like I am suggesting you will have a hard time not pushing the engine once in a while. Resistance is futile.

Lineslinger

VIP MEMBER

- Joined

- Feb 26, 2017

- Messages

- 1,831

Who is the mfg. of your Cobra and what engine are you running in it?Day 4 of the soak and still no movement.

I'm in no hurry...

I did receive some tools late today and I was able to remove the clutch and verify that the gearbox and rear wheel are turning fine.

The issue is definitely in the engine. Not shocked, but good to narrow it down for sure.

Also, thanks for helping me spend my money! I have been listening.

I have several buddies coming to visit tomorrow to check out the build so I stocked the fridge and spent some time getting the cobra cleaned up.

Not relevant to the build but it's a slow day and I wanted to provide some kind of update.

Look at the homemade tool thread on this site...lots of innovative ideas and applications.

Are the pistons still stuck?

RussellTx

VIP MEMBER

- Joined

- Jul 28, 2024

- Messages

- 60

I am indeed glad you don't live around here!Your lucky I don't live anywhere near you. I'd be pushing building a hot rodded up Norton.

For example, you could build a healthy engine while waiting for those pistons to free up. Molnar (TGA.co.uk) has cases, barrels, and a quality crank. JS Motorsport has some nice rods and pistons as well as valve train parts. AN has bearings and chains and other small necessary parts. If that head is junk, talk to Matt at cNw about an STS head. You could also think about a belt clutch. Oops there goes that $10K budget I mentioned, and you'd still need buffing compound, and probably wheels, brakes and the list goes on.

Save the soaking numbers matching cases for the next victim of Nortonitis.

That said you could also do it all stock, but the Cobra would be teasing the Norton about being so vanilla.

Watch out for that Woodinville Bourbon. It's smooth.

I agree with johnm about keeping the revs down once you get whatever version of Norton you decide on put together. Unfortunately, if you build an engine like I am suggesting you will have a hard time not pushing the engine once in a while. Resistance is futile.

You are a bad influence!

I'm not making any directional decisions until I get everything apart and see where I'm at.

The bike has been sitting for 40 years, there is no rush!

RussellTx

VIP MEMBER

- Joined

- Jul 28, 2024

- Messages

- 60

Thanks!Who is the mfg. of your Cobra and what engine are you running in it?

Look at the homemade tool thread on this site...lots of innovative ideas and applications.

Are the pistons still stuck?

Yep, pistons are still stuck...

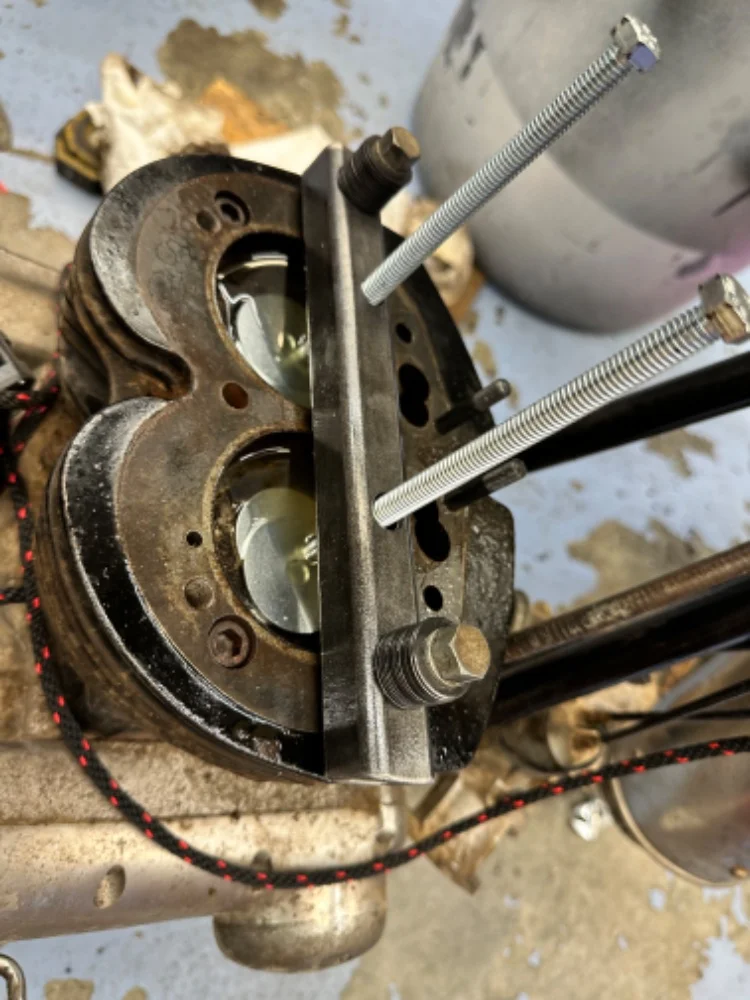

I ramped up the pressure on my contraption and stripped the threads on it.

Switched from ATF/Acetone and now I have some of the phosphoric acid that was recommended.

Next step is to beef up the contraption and see if I can break something.

I'm going to get pretty aggressive to the point that I will either break the beefed up contraption again, strip the head bolts or it will break free.

After that, I'm considering pulling the engine and using a 70mm hole saw. I will need to manage the pilot bit to keep it off the wrist pin but it could be the right size tp drill down to the fist ring slot.

Cobra is a Factory Five - 20th Anniversary Edition Roadster. It has a 351w DART block built out to a 427W with a Holley Terminator X TBI.

Below is a post on Facebook from the tuner.

This is a link to the Facebook post from the Tuner

"She's making 500ft lbs to the tire, in a 2400lb rocket ship. 430rwhp."

RussellTx

VIP MEMBER

- Joined

- Jul 28, 2024

- Messages

- 60

Success!

I beefed up the contraption and was able to push the pistons out of the cylinders.

It fought me the whole way out so I'm glad I had some long bolts in my bin to build it with.

I would tighten one side and then the other all the way out. I was able to hang some straps from my ceiling and use that to pull it the last little bit.

The bottom end turns very smooth and does not look too bad at first glance.

Is it an option to leave the bottom end as-is or is it best to go through everything since it's apart this far already?

I think I want to go through it all, but not if there is a good chance I'll screw it up worse in the process...

In short, how difficult is the rebuild process for a noob?

Also, if it's a high risk maneuver for a rookie, is there a good shop that could knock it out for me at a reasonable price?

BTW, I did crack open the Woodinville as a celebratory toast. It was indeed a great recommendation!

I beefed up the contraption and was able to push the pistons out of the cylinders.

It fought me the whole way out so I'm glad I had some long bolts in my bin to build it with.

I would tighten one side and then the other all the way out. I was able to hang some straps from my ceiling and use that to pull it the last little bit.

The bottom end turns very smooth and does not look too bad at first glance.

Is it an option to leave the bottom end as-is or is it best to go through everything since it's apart this far already?

I think I want to go through it all, but not if there is a good chance I'll screw it up worse in the process...

In short, how difficult is the rebuild process for a noob?

Also, if it's a high risk maneuver for a rookie, is there a good shop that could knock it out for me at a reasonable price?

BTW, I did crack open the Woodinville as a celebratory toast. It was indeed a great recommendation!

NORTSTER1974

VIP MEMBER

- Joined

- Aug 17, 2015

- Messages

- 309

JMWO, From the looks of it I would rebuild the motor. Who knows if the jugs are salvageable. Yikes! Open your wallet. You may have to start drinking cheaper beer?Success!

I beefed up the contraption and was able to push the pistons out of the cylinders.

It fought me the whole way out so I'm glad I had some long bolts in my bin to build it with.

I would tighten one side and then the other all the way out. I was able to hang some straps from my ceiling and use that to pull it the last little bit.

The bottom end turns very smooth and does not look too bad at first glance.

Is it an option to leave the bottom end as-is or is it best to go through everything since it's apart this far already?

I think I want to go through it all, but not if there is a good chance I'll screw it up worse in the process...

In short, how difficult is the rebuild process for a noob?

Also, if it's a high risk maneuver for a rookie, is there a good shop that could knock it out for me at a reasonable price?

BTW, I did crack open the Woodinville as a celebratory toast. It was indeed a great recommendation!

johnm

VIP MEMBER

- Joined

- Feb 26, 2008

- Messages

- 1,836

Excellent progress.

If it were me I'd split the cases and do the crank mods I talked about.

But. That needs work above what most can do and you would need a good machine shop.

Have you still got the oil filter? If so pull the element out and have a good hard look. Put a magnet over it looking for any steel fragments. Drain and flush the oil tank looking for anything nasty or a build up of sludge. Likewise the sump filter.

I could recommend you a good shop to do everything down here but that's no use to you. I'd look for US guys and ask for recommendations on a good shop. That's what I'd do.

But this bike doesn't have many miles and if you don't find any nasty surprises and it's a play bike for small weekend runs then 90 % of the time you'd probably get away with not splitting the cases.

If it were me I'd split the cases and do the crank mods I talked about.

But. That needs work above what most can do and you would need a good machine shop.

Have you still got the oil filter? If so pull the element out and have a good hard look. Put a magnet over it looking for any steel fragments. Drain and flush the oil tank looking for anything nasty or a build up of sludge. Likewise the sump filter.

I could recommend you a good shop to do everything down here but that's no use to you. I'd look for US guys and ask for recommendations on a good shop. That's what I'd do.

But this bike doesn't have many miles and if you don't find any nasty surprises and it's a play bike for small weekend runs then 90 % of the time you'd probably get away with not splitting the cases.

htown16

VIP MEMBER

- Joined

- Apr 29, 2009

- Messages

- 1,530

If you have it this far apart, I would go ahead and take it the rest of the way. Norton bottom ends are straight forward to work on. It looks like there was moisture in there. Check the main bearing condition looking for pitting. If any doubt replace the main bearings. Heat the cases to remove. Use a bearing splitter on the drive side inner. Mike the crank journals. If the crank looks good at least put new standard rod bearings in or have reground if worn. Disassemble the crank and clean the sludge trap. Reassemble with new crank hardware. Carefully inspect cam and lifters and cam bushings. Reassemble the cases with tribond sealer. Send timing side cover and oil pump out for AMR mods to prevent wet sumping.

Cylinders may clean up with an overbore hard to tell from pics. You need to find a competent machine shop. Also for any head work. Need to mike valve guides and valve stems to assess if guides need replaced. If you could add your location people on here could make some recommendations as to finding a good machine shop.

www.amr-of-tucson.com

www.amr-of-tucson.com

Cylinders may clean up with an overbore hard to tell from pics. You need to find a competent machine shop. Also for any head work. Need to mike valve guides and valve stems to assess if guides need replaced. If you could add your location people on here could make some recommendations as to finding a good machine shop.

Anti Wet Sump Information – Nortec

www.amr-of-tucson.com

www.amr-of-tucson.com

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,851

According to your first post “It had some engine troubles in the 80's and has been in my Dad's garage ever since”… I’d suggest it’s worth stripping it for this reason alone.

Also, looking at your cars, you’re a guy who likes things done right, so stripping the motor seems a no brainer to me. The big ends could’ve been sat metal on metal for decades damaging the bearing material, the oil seals will likely be hardened, etc. Plus, you don’t know what shite is in there !

A Norton motor is SO simple to work on and there’s SO much advice available on what to do.

You’ve got the Norman White book already, now get yourself the Mick Hemmings engine and gearbox rebuild DVDs, and get stuck in, I really don’t think you’ll regret it.

But that said, if you don’t fancy doing it, perhaps drop Greg Marsh a PM…

Also, looking at your cars, you’re a guy who likes things done right, so stripping the motor seems a no brainer to me. The big ends could’ve been sat metal on metal for decades damaging the bearing material, the oil seals will likely be hardened, etc. Plus, you don’t know what shite is in there !

A Norton motor is SO simple to work on and there’s SO much advice available on what to do.

You’ve got the Norman White book already, now get yourself the Mick Hemmings engine and gearbox rebuild DVDs, and get stuck in, I really don’t think you’ll regret it.

But that said, if you don’t fancy doing it, perhaps drop Greg Marsh a PM…

Last edited:

Similar threads

- Replies

- 29

- Views

- 2,623