- Joined

- Sep 15, 2020

- Messages

- 567

I always use heat with penetrating oil, the magic temp being about 300F to make press-in bearings and such come free (gas BBQ is my friend). But that's steel surrounded by aluminum so it's a different kettle of greasy fish and chips, expansion-wise. I wonder if a bag of ice, or dry ice on the piston tops while heating the barrels might persuade them to part company? Aluminum reacts to temp pretty radically compared to steel so perhaps it may contract? Dunno just guessing.I'll try anything at this point!

I just have penetrant in there at this point.

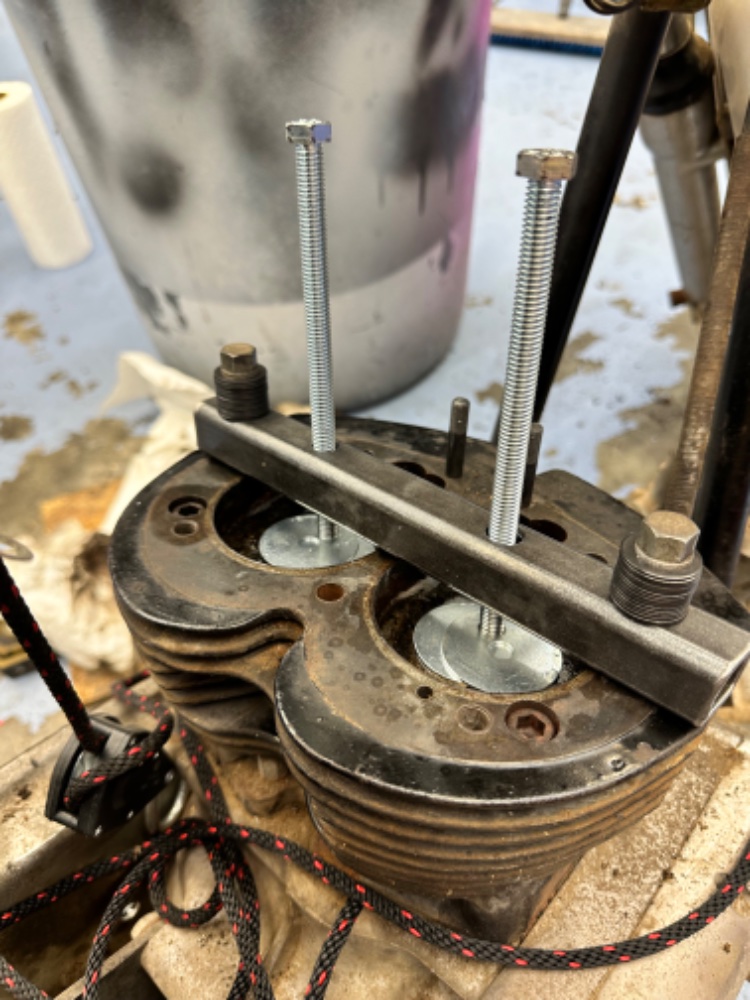

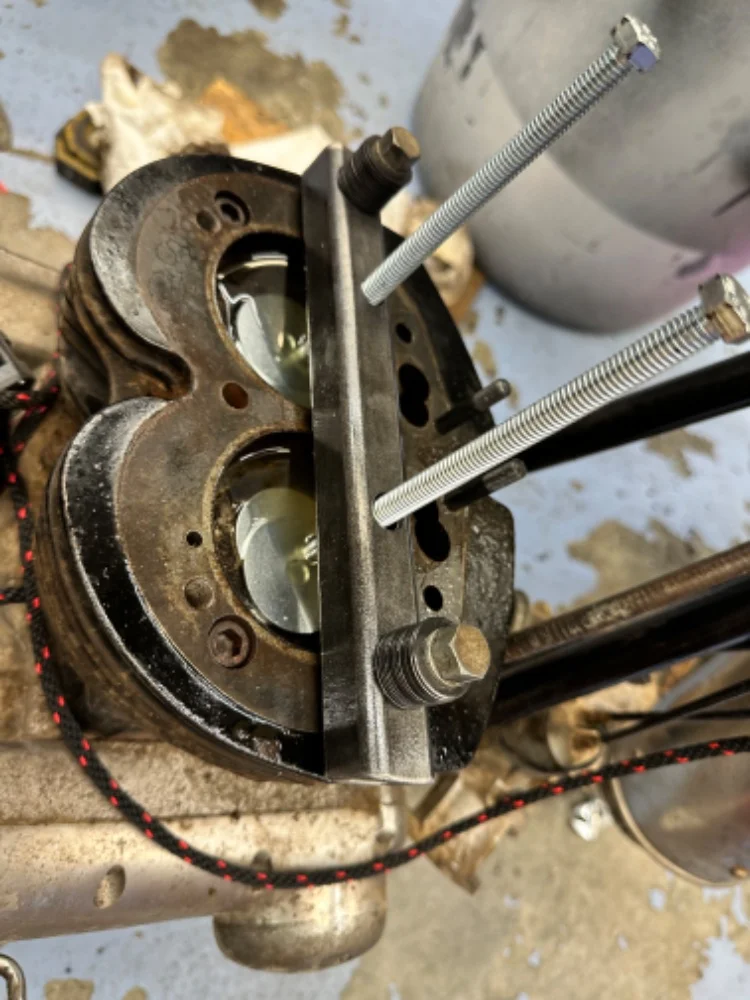

I rigged up a little contraption to put some steady pressure on it and now I'm going to have a pint...

What could go wrong?