marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 4,932

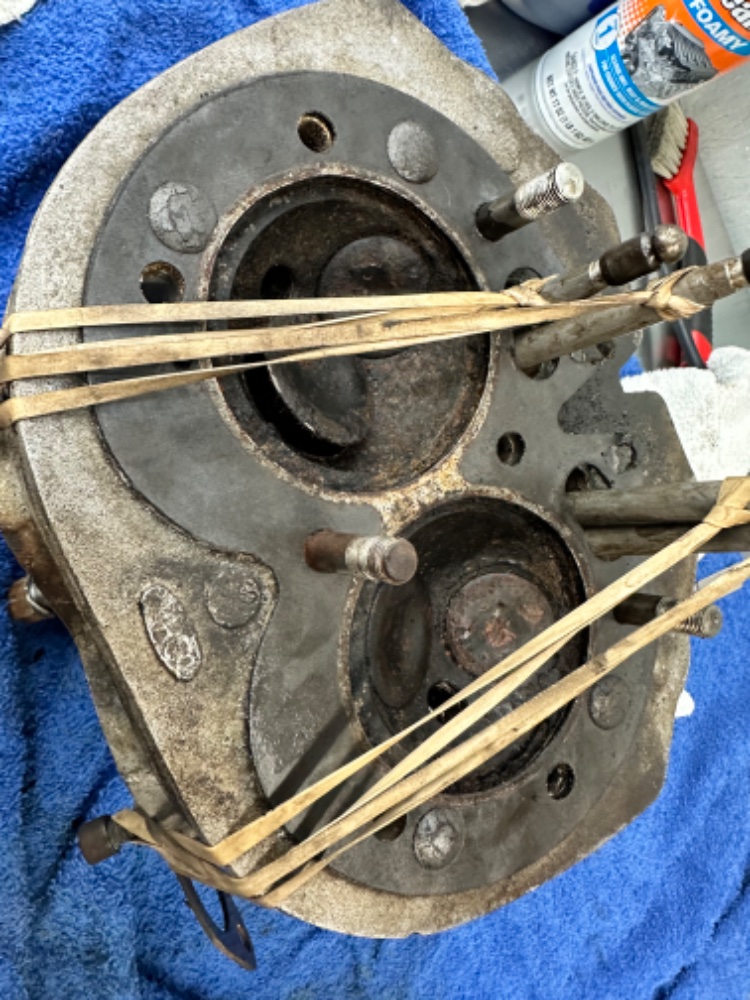

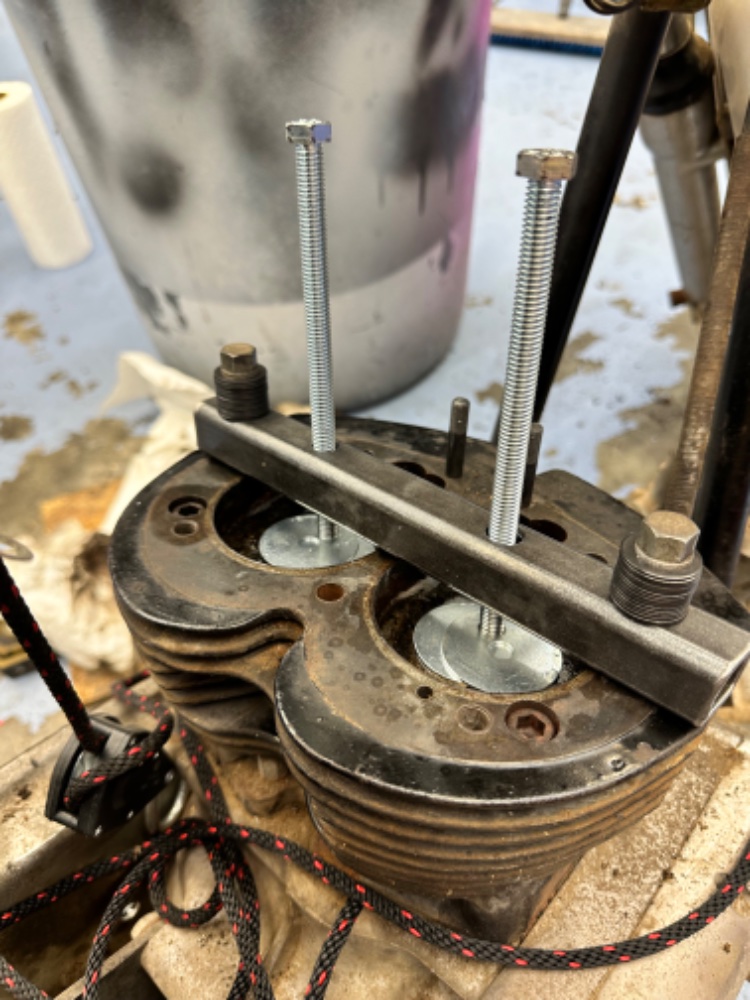

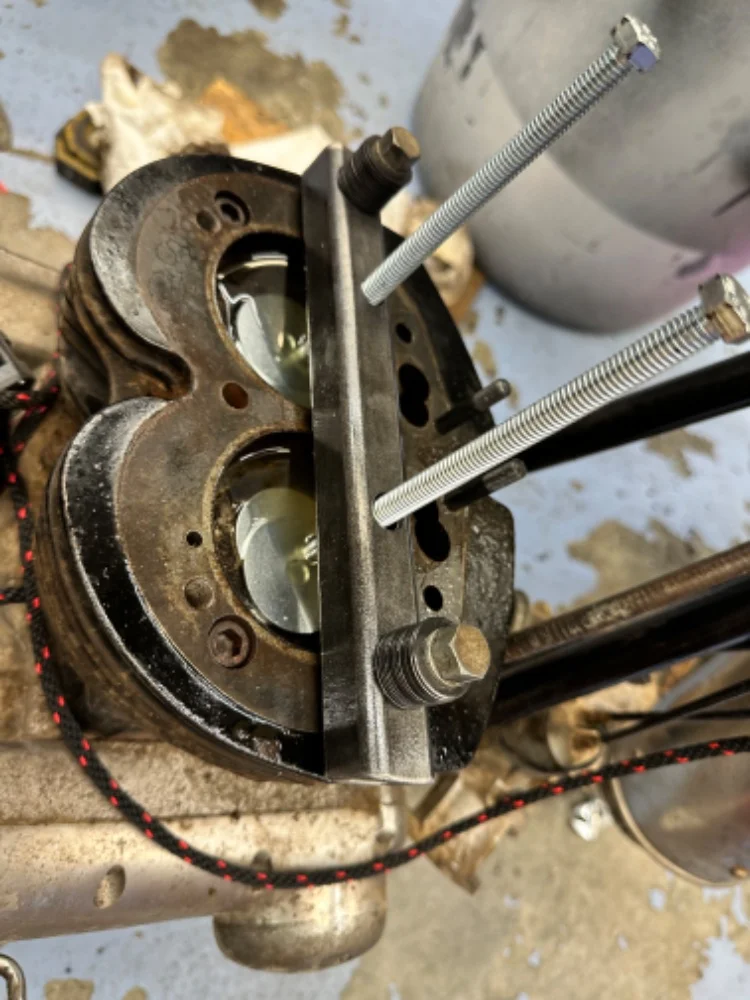

The pistons are always at the same level - they go up and down together. The head will come off no matter where the pistons are but it's much easier with a helper.Since the engine is locked up, I had to skip the step where you rotate the engine to TDC to get the most room to get the head past the rods while still in the frame (spoiler alert). Finally got the head free as it was stuck pretty good and both pistons are at the exact same level (so not TDC). Also both cylinders are full of what looks like coffee grounds and the walls are NOT smooth...