- Joined

- Dec 3, 2012

- Messages

- 3,727

Wow, this is hard work.

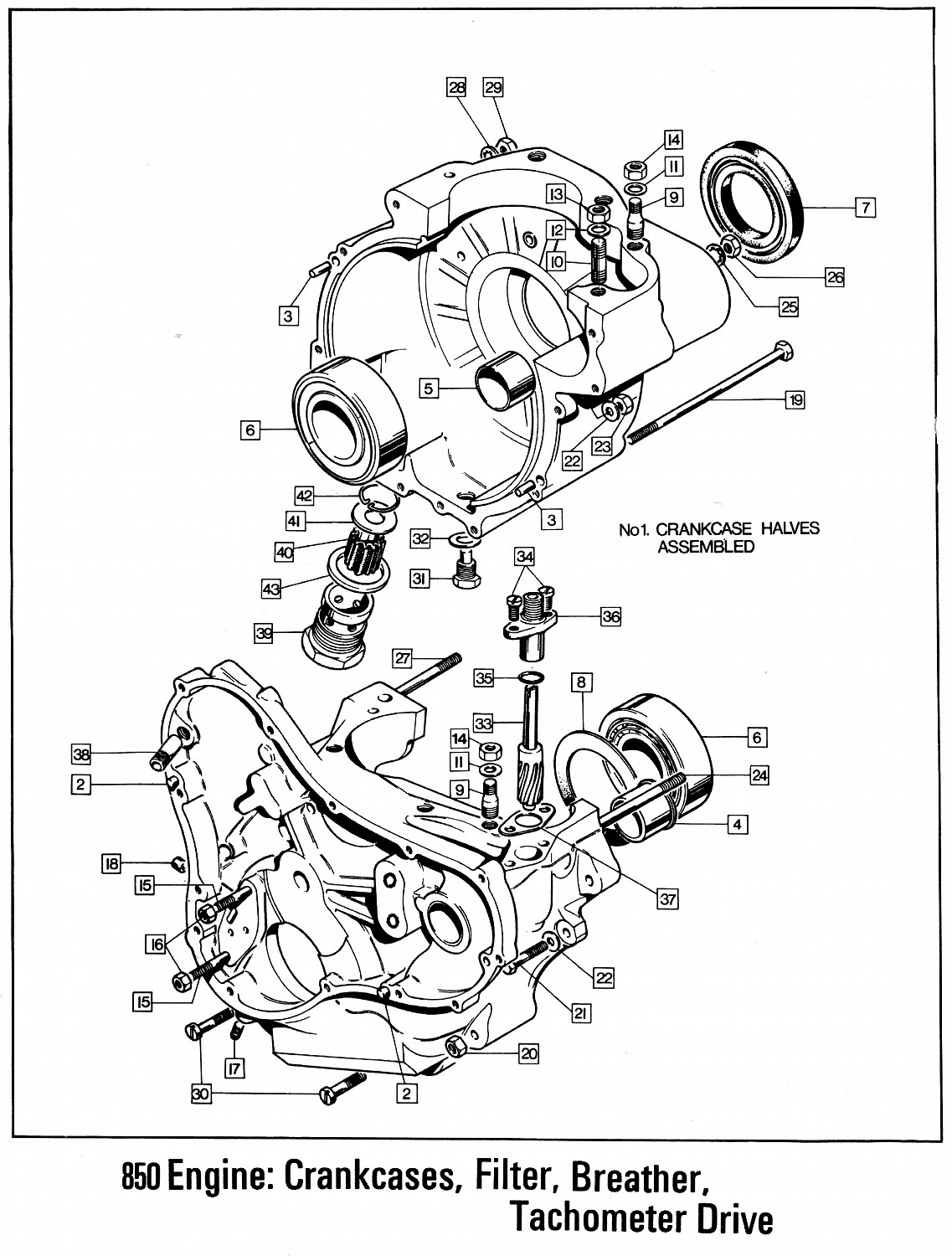

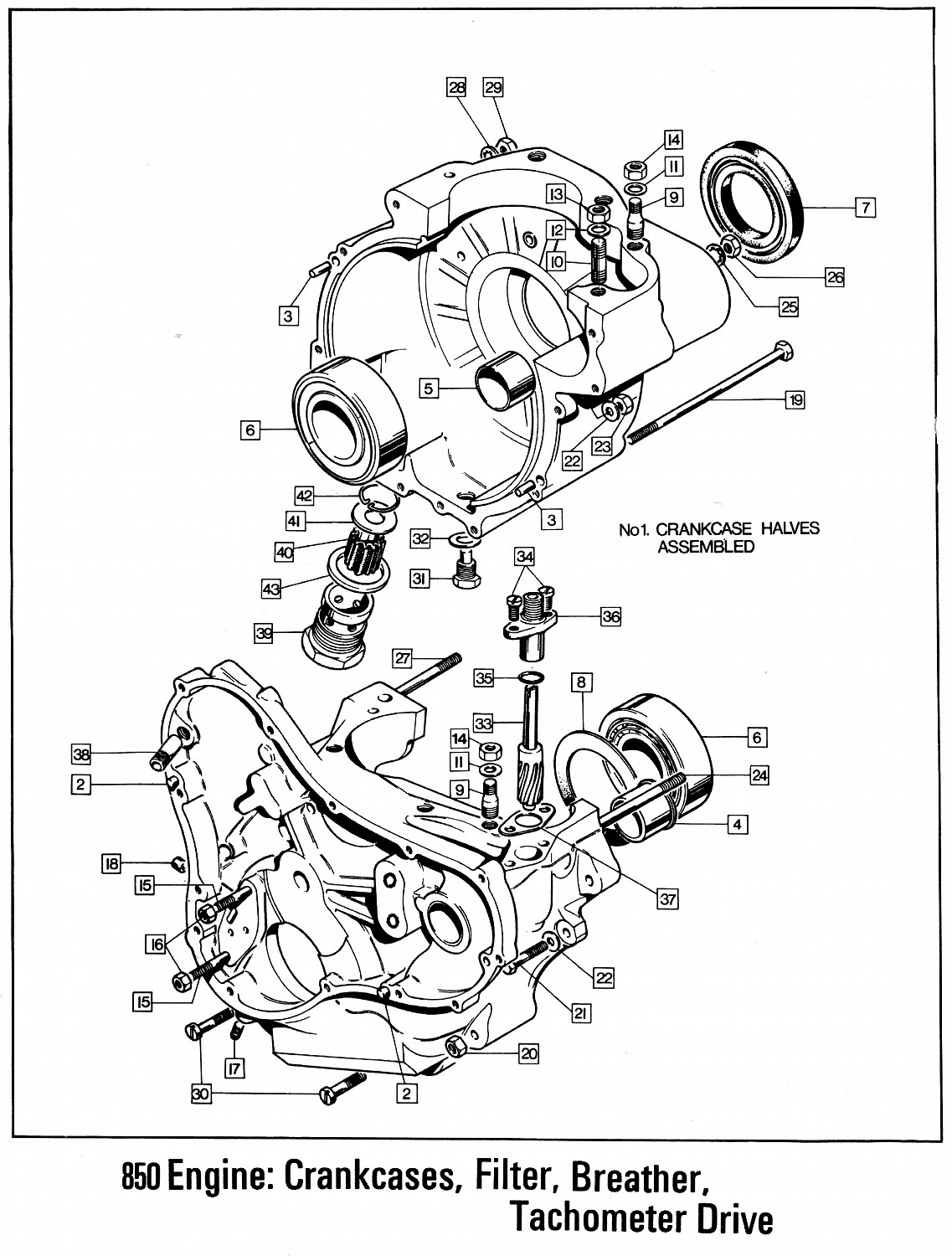

Item 8 / part number 06.7569

As you can see with a new picture with an original main bearing from my Mk2a 850 for size comparison and the same part number 06.7569 on the unopened AN shim bag it is a small diameter shim unlike the ones that go in the engine case (which AN do not make or ever have)

I seem to remember I bought these shims based off the same muppet AN picture only to have these arrive to be of no use, as posted before, free to a good home.

I won't ask how a shim the size of the inner races shoulder hard pressed against the crankshaft was removed without moving the inner itself.

What JC has said in the past is. (and there might be other posts)

"Because when the end float is less than about .010 on a stock motor or .015 on a high revving race motor you will start to see damage on the ends of the superblend rollers and the thrust surface of the races.

The crank actually gets longer as the revs increase."

With Wellseal I have around 0.013" + on a stock engine which I deem close enough.

I would be surprised if the cases did not grow as they get hot.

If the means to adjust the float or someone could not be bothered it would all be a moot point.

Andover Norton Parts Drawings - Genuine Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.

andover-norton.co.uk

Item 8 / part number 06.7569

As you can see with a new picture with an original main bearing from my Mk2a 850 for size comparison and the same part number 06.7569 on the unopened AN shim bag it is a small diameter shim unlike the ones that go in the engine case (which AN do not make or ever have)

I seem to remember I bought these shims based off the same muppet AN picture only to have these arrive to be of no use, as posted before, free to a good home.

I won't ask how a shim the size of the inner races shoulder hard pressed against the crankshaft was removed without moving the inner itself.

What JC has said in the past is. (and there might be other posts)

"Because when the end float is less than about .010 on a stock motor or .015 on a high revving race motor you will start to see damage on the ends of the superblend rollers and the thrust surface of the races.

The crank actually gets longer as the revs increase."

With Wellseal I have around 0.013" + on a stock engine which I deem close enough.

I would be surprised if the cases did not grow as they get hot.

If the means to adjust the float or someone could not be bothered it would all be a moot point.

Last edited: