(20

M3S/140)

Ok, that narrows it down a lot.

They would probably benefit from a clean, regardless. Maybe invest in a new set of Barnett, etc. friction plates (and perhaps a new clutch centre, see below).

The bronze plates also need cleaning periodically and the clutch centre spines inspected for notching because that can cause clutch drag if perhaps bronze plates have been used with the old unhardened four-pate centre but the hardened centres still wear.

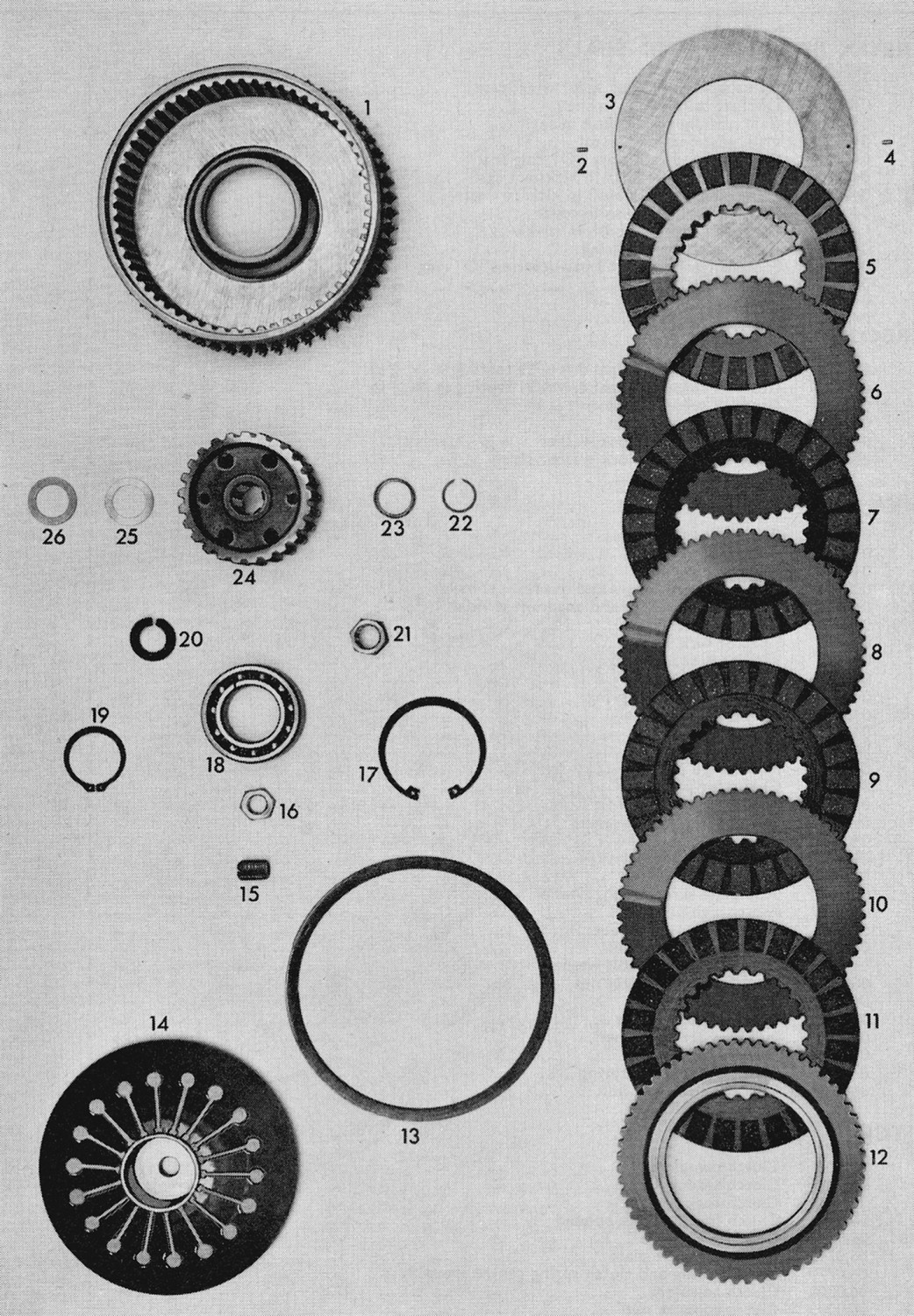

The original clutch would have had four 'postage stamp' friction plates, three plain plates and a 'thick' pressure plate...

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.

andover-norton.co.uk

The later 'bronze' plate clutch had five bronze, four plain and a 'thin' pressure plate...

https://andover-norton.co.uk/en/shop-drawing/207/chaincases-chains-sprockets-clutch-alternator

A 1" pivot radius could be ok, (7/8", might not) I can only suggest you back off the clutch pushrod adjustment to 1/3 - 1/2 a turn as mentioned and see if that's an improvement.