Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,849

In a water cooled engine, does the sensor actually sit in the water and measure water temperature, or is it into a blind hole and measuring the cylinder head metal temperature?

I’m wondering if this could be a source of some people troubles?

https://rover.ebay.com/rover/0/0/0?mpre=https://www.ebay.co.uk/ulk/itm/360183075288. This is the stuff that’s a must, I use it on dry pocket thermistor s on gas boilers,the sensor head is free from scale or Muck then to give an accurate reading, my 2016 bike is running fine 16,000 miles on start up it ticks over at 1500 revs, warms up & drops to 1250 approx, I’m sure they must be ok for the job,it there is a lack of heat sink compound around the sensor end then that can effect it even if the sensors newHow are your new bikes running ? Here in the states if you ordered a New 961 it would be a Euro3 with Omex ECU. How are the Euro3 Omex bikes running ? Can anybody share ? Richard Pearce possibly .

How are your new bikes running ? Here in the states if you ordered a New 961 it would be a Euro3 with Omex ECU. How are the Euro3 Omex bikes running ? Can anybody share ? Richard Pearce possibly .

I still have a nagging doubt about the choice of sensor, but I’m well out of my depth with it, so will just have to hope and assume it’s fit for purpose.

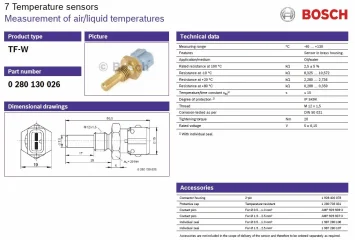

If we could get to look at the Bosch data book for that sensor. It would give good information. My only worry would be if the sensor is exposed to temperatures beyond its design range. BMW air cooled bikes may be doing something similar ?

Tony,

When did BMW switch from the airhead to water pumpers on their R1200 line?

2014, 2015?

I wonder which Bosch sensors the late model EFI airheads used?

If we could get to look at the Bosch data book for that sensor. It would give good information. My only worry would be if the sensor is exposed to temperatures beyond its design range.

Hello FE , Are the new bikes with problems having to go back repeatedly ? I remember that GLB had his SC ECU replaced with a Euro 3 Omex , and I wonder how its going for him ? I know its expensive , but if the Euro 3 OMEX has been sorted and works well this may be the way forward for the SC guys. I would love to hear from all of our Euro 3 OMEX owners.How the new bikes are running is a bit of a mixed bag it seems Tony. Mine, and others, have been flawless, others have reported repeat returns to factory / dealer on new machines.

Thanks to you & Blighty for the conductivity paste reminder though (I’ve got some in the way). Being manually applied could easily lead to discrepancies in production. And if it’s as important to the function as it appears, this should be top of the list for fault finding I’d say.

I still have a nagging doubt about the choice of sensor, but I’m well out of my depth with it, so will just have to hope and assume it’s fit for purpose.

... or inconsistent application of conductivity paste