- Joined

- Jul 25, 2010

- Messages

- 5,947

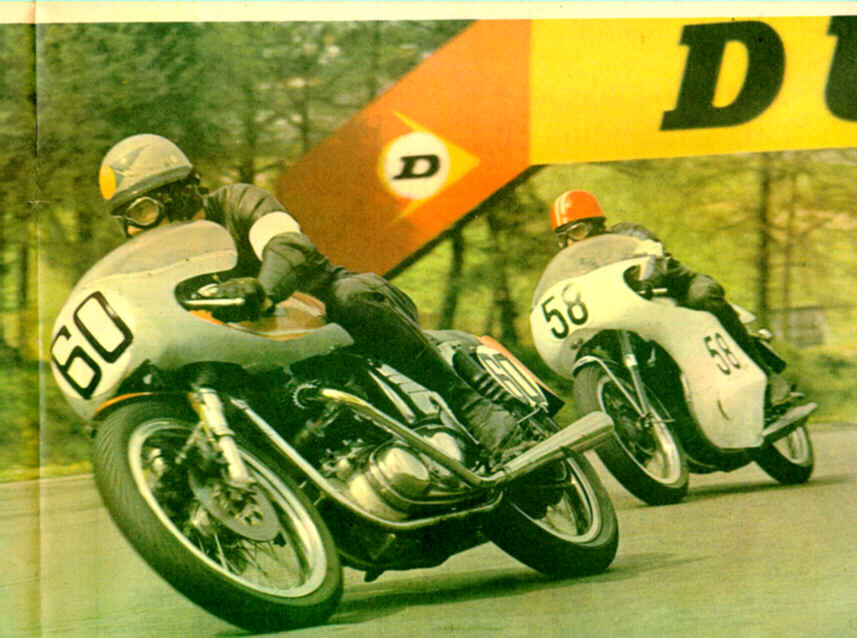

STEVE LANCEFIELD patented the canted motor Vs v i b r a t i o n principal , so we're told .

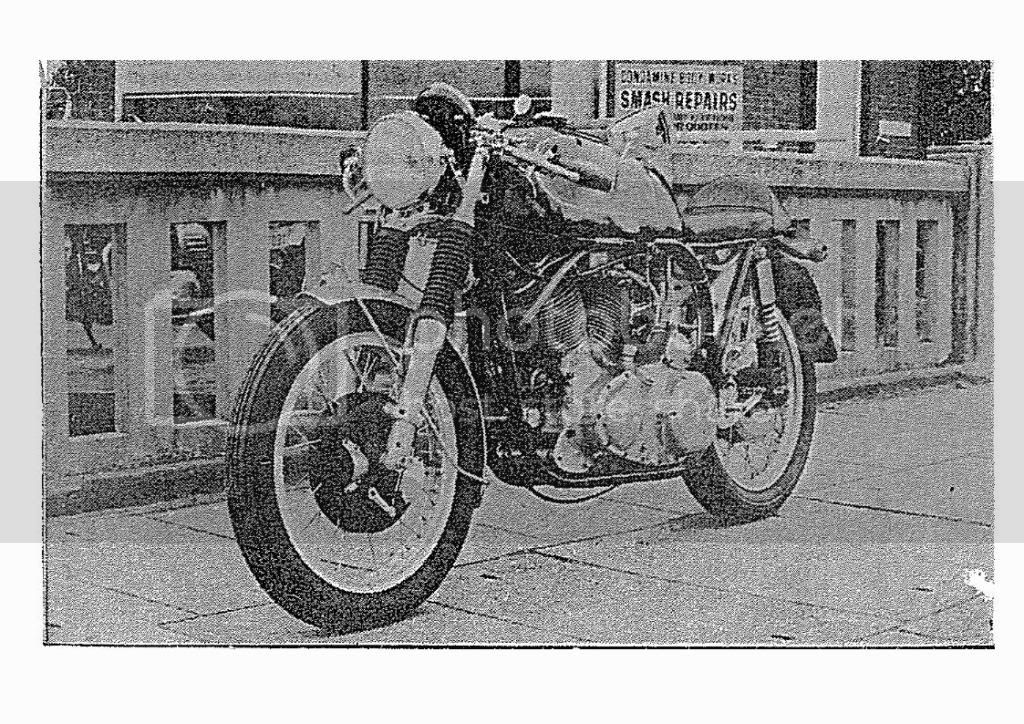

If your metickoless , you might keepup . ' period ' 7R brake , manx chassis , H.R.D. motorvation . In Sydney around 1970 .

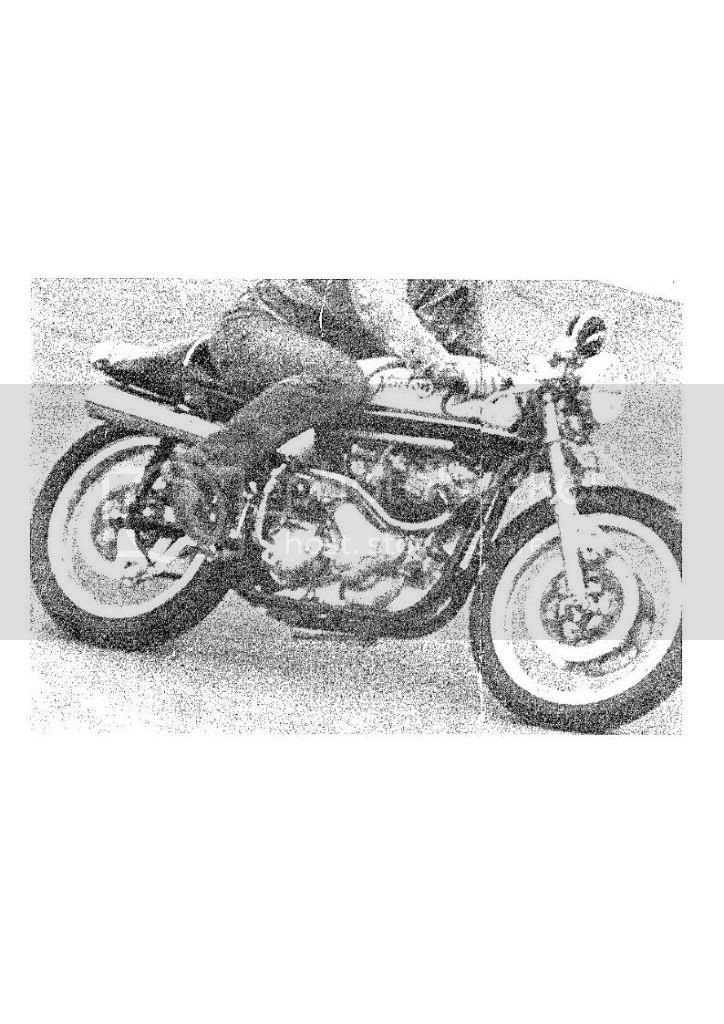

Thisis from early 70s , maybe ' Big bike ' . A Californ eye A Combat Manx . ( you can see you could spead motor & box more . )

But this probably more like yours if a Slim Line . GRINDING EXHAUST PIPES helps you fall off . So see they dont .

If your filthy rich , just by a domiracer Chassis ,

Take it out to 920 . ( Cortina Pistons ) or sleeve & 960 . Ditto . fairly bulletproof , in a speedway outfit . Fairly STOCK ( Factory parts ) & it'd choke itself before it blew . 2 S cam .

If your metickoless , you might keepup . ' period ' 7R brake , manx chassis , H.R.D. motorvation . In Sydney around 1970 .

Thisis from early 70s , maybe ' Big bike ' . A Californ eye A Combat Manx . ( you can see you could spead motor & box more . )

But this probably more like yours if a Slim Line . GRINDING EXHAUST PIPES helps you fall off . So see they dont .

Hello guys,

one semply question.

Do you have driven a special motorcycle with Featherbed frame and Commando engine?

I attend your impressions.

Thanks.

Gian

one semply question.

Do you have driven a special motorcycle with Featherbed frame and Commando engine?

I attend your impressions.

Thanks.

Gian

- Gian85

- Replies: 126

- Forum: Norton Commando Forum

If your filthy rich , just by a domiracer Chassis ,

Take it out to 920 . ( Cortina Pistons ) or sleeve & 960 . Ditto . fairly bulletproof , in a speedway outfit . Fairly STOCK ( Factory parts ) & it'd choke itself before it blew . 2 S cam .

Last edited: