Believe me , the prototypes were tested hard, but initially it was all on public roads. I was doing 500 miles a day (4 a.m to noon) and a second rider did the same from 4 p.m. until midnight. We did it 6 days a week up to 25,000 miles. We also did high-speed endurance testing at the Motor Industry Research Assocication test center near Nuneaton.

With the benefit of hindsight, we should have also tested in MIRA's "Belgian Pave" track. This is a very uneven track made of cabble-stones. My uncle was a test driver the Leyland Motors (the bus manufacturer). He was sent off to MIRA to test on the Belgian Pave with suppies and funding for a month of testing. He was back at the Leyland factory after just three days with all the passenger seat frames broken off at their floor mountings.

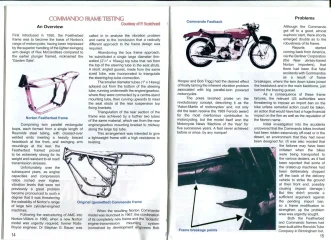

If we'd tested the Commando on that Pave track, I think we'd have found the top tube problem real early.

The AJS motocross bikes (later marketed as the "Stormer" ) originally had a similar frame design to the Commando, except the top tube was welded close to the bottom of the headstock. We had several failures, similar to the Commando, but round the top half of the tube. On one occasion, I took the gas tank off the bike we'd used at a race, to find that the tank was the only thing keeping the frame together. Motocross was a very punishing activity.

The frame was redesigned with a tapered top tube, made up of two half-round sections with a long triangular spacer welded between on both sides. It was circular at the rear and "obround" at the headstock. Wolverhampton's development engineers tried to convince the Commando folks to use a similar design, but they considered it "too complicated".