Larry S

VIP MEMBER

- Joined

- Apr 15, 2020

- Messages

- 709

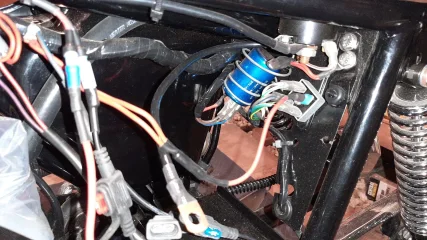

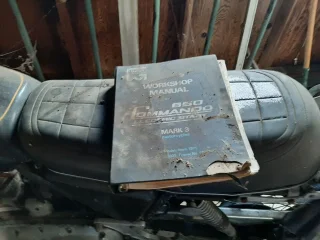

Thank you very much for sorting this out for me. I will insulate the double red ring connector also, thanks.Yes. If you have a 12V battery you can check the solenoid operation by connecting the battery to the WR ('S') terminal and ground or the metal plate of the solenoid when you should then hear it click.