Thanks for visiting Access Norton

- Guest view limit reached

- Create a free account (more details)

- Already a member? Click here to login

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mk3 Primary

- Thread starter Mart UK

- Start date

- Status

- Not open for further replies.

- Joined

- Mar 11, 2021

- Messages

- 1,411

Thought it over. The clutch plates are pretty much dry, just a minor trace of oil on the innermost, nearest that gearbox shaft seal. I didn't sense the clutch slipping, once I had the cable adjusted (at the handlebar lever). So, I think I will leave this alone and just focus on getting what I've done so far back together and working as it should. But, please shout if you think that's a mistake.My transmission shaft was not centered in the inner primary and had been a source of an oil leak. It had run that way so long (maybe from new) that when I removed the seal it was permanently offset by 1/8'". I loosened everything up and found enough wiggle room to center it up but became frustrated trying to keep it that way as I tightened things up. So I turned a little jig out of some PVC fittings, inside bore the dia of the gear shaft and outside dia the size of the inner primary hole. That held all in place while I tightened it all up.

The stud you refer to is the chaincase steady and needs to be tightened up when every thing else is tight as to not push or pull but just support the inner primary.

- Joined

- Nov 20, 2004

- Messages

- 21,110

Thought it over. The clutch plates are pretty much dry, just a minor trace of oil on the innermost, nearest that gearbox shaft seal. I didn't sense the clutch slipping, once I had the cable adjusted (at the handlebar lever). So, I think I will leave this alone and just focus on getting what I've done so far back together and working as it should. But, please shout if you think that's a mistake.

If the clutch isn't slipping or dragging then there's nothing to worry about.

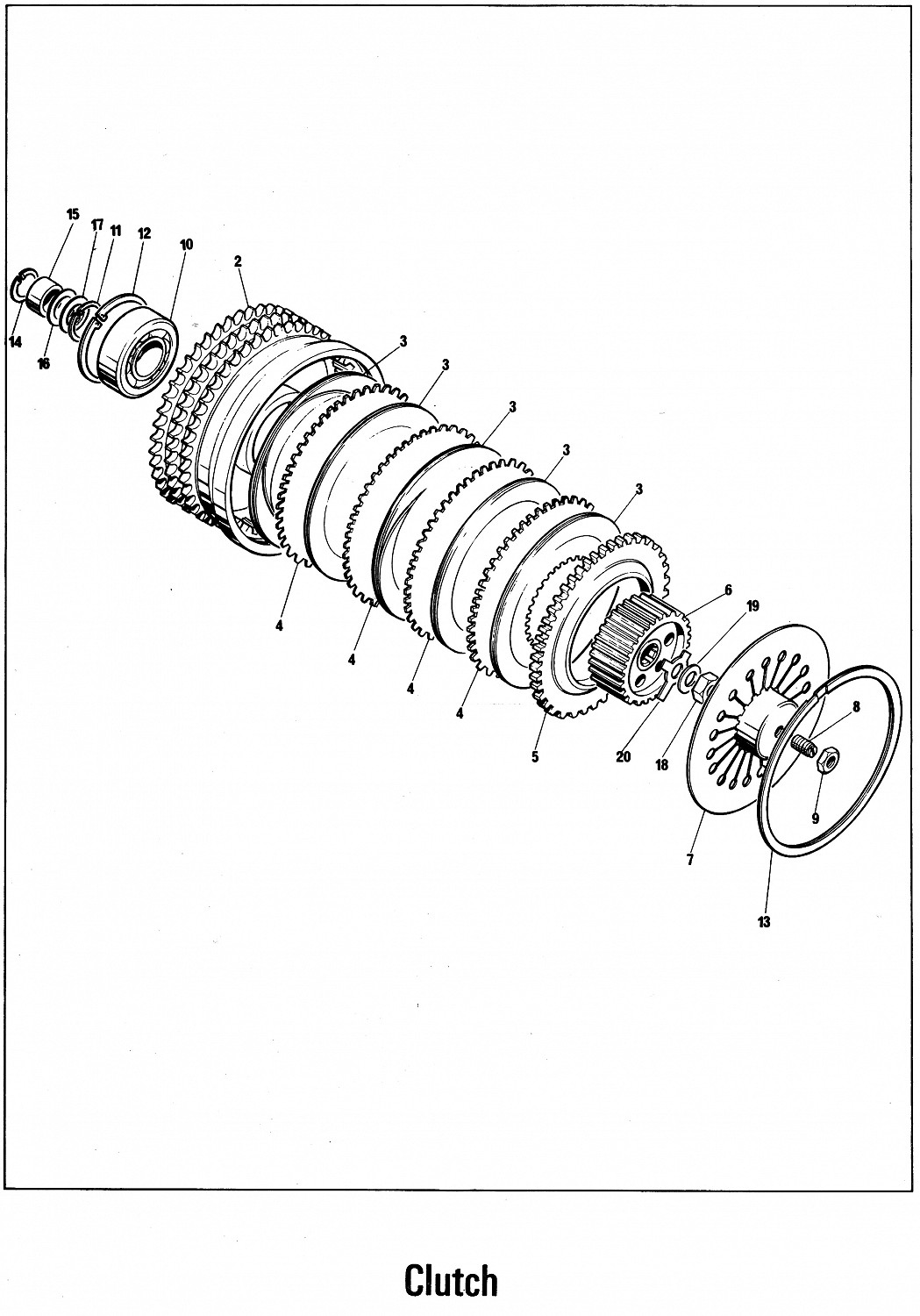

There will usually be some oil in the clutch assembly and the clutch bearing '10' requires lubrication.

Andover Norton Parts Drawings - Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.

andover-norton.co.uk

I've got one of these and it seals quite well:The Mk3 gasket alone should seal the joint. I normally grease the gasket as it is often reusable but if the joint face is damaged then sealant could be required but perhaps only apply it to the inner case side of the gasket and grease on the outside.

The problem area as you said is the lower screw hole where the joint face of the inner case is thinner and where oil could leak along the screw thread which might require sealant on the thread.

NORTON Commando Outer Primary Cover Gasket for 1975 850cc - Silicone Gaskets - Real Gaskets Tennessee

OUTER PRIMARY COVER GASKET - SILICONE - fits NORTON - COMMANDO 850 cc Part #: RG-06-5534. One silicone gasket - 1/32" thick. These silicone rubber gaskets are made from aerospace mechanical grade AMS silicone and designed to withstand temperatures up to 400 degrees Fahrenheit. Reusable...

It's reusable, sort of. Since it has to be applied perfectly dry there's nothing to hold it in place. It's not too difficult when brand new but on the re-use it's slightly stretched and has lost any cling that helps on the first use. Since it's expensive and marketed as reusable I was determined to reuse it and was ultimately successful. This is not an endorsement as such but it does seal completely without any sealant. Surfaces MUST be completely clean and dry.

- Joined

- Mar 11, 2021

- Messages

- 1,411

All done.

Thank you for your advice and answering my questions.

Bike currently starts first time. Clutch adjustment was a voyage of discovery. Now understand. Clutch pull is now 2 fingers. Whether due to the correct adjustment, a general clean up, or the new clutch hub, IDK. But easier pull, easier to find neutral and no slip, so far.

The pistons on the chain tensioners needed a bit of fettling to glide smoothly. Now working. The old sprag (14T) was noticeably sloppier than the new one. The old primary chain was about 5mm + longer than the new one I used grease on the primary gasket faces. No leak after the first ride (10 miles). Would be lovely if that proves to be a fix.

Really grateful for the help. Tyres replaced tomorrow, transmission oil Thursday, then longer ride on Friday. ;-)

Martin

Thank you for your advice and answering my questions.

Bike currently starts first time. Clutch adjustment was a voyage of discovery. Now understand. Clutch pull is now 2 fingers. Whether due to the correct adjustment, a general clean up, or the new clutch hub, IDK. But easier pull, easier to find neutral and no slip, so far.

The pistons on the chain tensioners needed a bit of fettling to glide smoothly. Now working. The old sprag (14T) was noticeably sloppier than the new one. The old primary chain was about 5mm + longer than the new one I used grease on the primary gasket faces. No leak after the first ride (10 miles). Would be lovely if that proves to be a fix.

Really grateful for the help. Tyres replaced tomorrow, transmission oil Thursday, then longer ride on Friday. ;-)

Martin

- Joined

- Mar 11, 2021

- Messages

- 1,411

Was searching for something and came across this topic. Thought I would give a conclusion now, 2,000 miles on.

The new AN sprag, gear, bearing, primary chain etc. are still working fine. I think the root cause was an incorrect spacer in the upper hydraulic chain tensioner (a heavier Allen headed metal bolt was used), coupled with the bottom one assembled incorrectly, caused the top tensioner to seize fully in. This pushed the lower tensioner fully out all the time. The chain was running against the bottom of the inner case, wearing a groove. Lots of small alloy particles made a nice paste which was visible in the sprag clutch, causing wear. At the same time i had a slightly undersized battery (12Ah) and the bullet connectors to the alternator were loose, so I didn't have a full battery to start the bike.

Challenging conditions! The clutch hub looked well worn too.

The strip and clean of inner, outer cases and both ends of the primary, replacement parts and a new clutch hub, SEEM to have sorted it out and significantly lightened my clutch lever. I've replaced the primary oil a couple of times since and it shows no sign of the metal particles. I've just completed a 2nd full service on the bike added a Holland NW breather valve, re-torqued the head and I'm nearly totally oil tight! All learnt from the forum. I've just renewed my subscription

I took advantage of yesterday's sunshine and rode about 30 miles up the coast to a cafe. Bike rode beautifully and when I pulled up a crowd of 5 bikers got up to have a look at my Commando. A moment of genuine pride. There's still a few things needing TLC and some things I'm puzzled by (e.g. inconsistent oil level readings) and I'll enjoy working through them.

I could not have done this myself without the guidance I received from the forum. I'm grateful.

P.s. I am now running an Interstate set up and with the UK's current fuel supply problems, my 5+ gallon Commando has become a fuel tanker for my other bikes!

The new AN sprag, gear, bearing, primary chain etc. are still working fine. I think the root cause was an incorrect spacer in the upper hydraulic chain tensioner (a heavier Allen headed metal bolt was used), coupled with the bottom one assembled incorrectly, caused the top tensioner to seize fully in. This pushed the lower tensioner fully out all the time. The chain was running against the bottom of the inner case, wearing a groove. Lots of small alloy particles made a nice paste which was visible in the sprag clutch, causing wear. At the same time i had a slightly undersized battery (12Ah) and the bullet connectors to the alternator were loose, so I didn't have a full battery to start the bike.

Challenging conditions! The clutch hub looked well worn too.

The strip and clean of inner, outer cases and both ends of the primary, replacement parts and a new clutch hub, SEEM to have sorted it out and significantly lightened my clutch lever. I've replaced the primary oil a couple of times since and it shows no sign of the metal particles. I've just completed a 2nd full service on the bike added a Holland NW breather valve, re-torqued the head and I'm nearly totally oil tight! All learnt from the forum. I've just renewed my subscription

I took advantage of yesterday's sunshine and rode about 30 miles up the coast to a cafe. Bike rode beautifully and when I pulled up a crowd of 5 bikers got up to have a look at my Commando. A moment of genuine pride. There's still a few things needing TLC and some things I'm puzzled by (e.g. inconsistent oil level readings) and I'll enjoy working through them.

I could not have done this myself without the guidance I received from the forum. I'm grateful.

P.s. I am now running an Interstate set up and with the UK's current fuel supply problems, my 5+ gallon Commando has become a fuel tanker for my other bikes!

The AN engine sprocket is made from steel with a tougher core than it had originally, it was one of the changes I made just after I joined AN. We were retailing well before STS rang and offered to sell some of his tough versions to AN.

I have also recently checked the working envelope of the Cross and Morse 14 sprag and the envelope is very nearly the same as the 18 sprag, 0.002mm nominal difference on the sprocket. There is also the renold sprag, but that uses a different envelope. Any sprag might work with original 70's mating parts, depending on the barn door grinding practices and acceptance of parts by a company in administration at the time, best of luck on that, though some have success it seems.

The Chinese sprags on aliexpress mostly say to use the 18 sprag tolerance of mating parts, interesting as the dimensions of the Chinese sprag and the shape of the sprag differ considerably compared to the AN German sprag.

I have also recently checked the working envelope of the Cross and Morse 14 sprag and the envelope is very nearly the same as the 18 sprag, 0.002mm nominal difference on the sprocket. There is also the renold sprag, but that uses a different envelope. Any sprag might work with original 70's mating parts, depending on the barn door grinding practices and acceptance of parts by a company in administration at the time, best of luck on that, though some have success it seems.

The Chinese sprags on aliexpress mostly say to use the 18 sprag tolerance of mating parts, interesting as the dimensions of the Chinese sprag and the shape of the sprag differ considerably compared to the AN German sprag.

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 654

- Replies

- 13

- Views

- 1,391