I’m installing a new three phase rotor and stator in my 72 after re-shimming the inner chaincase. The right hand stator mounting stud is off about 1 mm to the left. This is pushing the stator off the rotor to the left, thereby widening the rotor-stator gap on the left and decreasing the gap on the right to below .008” spec’d in the Manual.

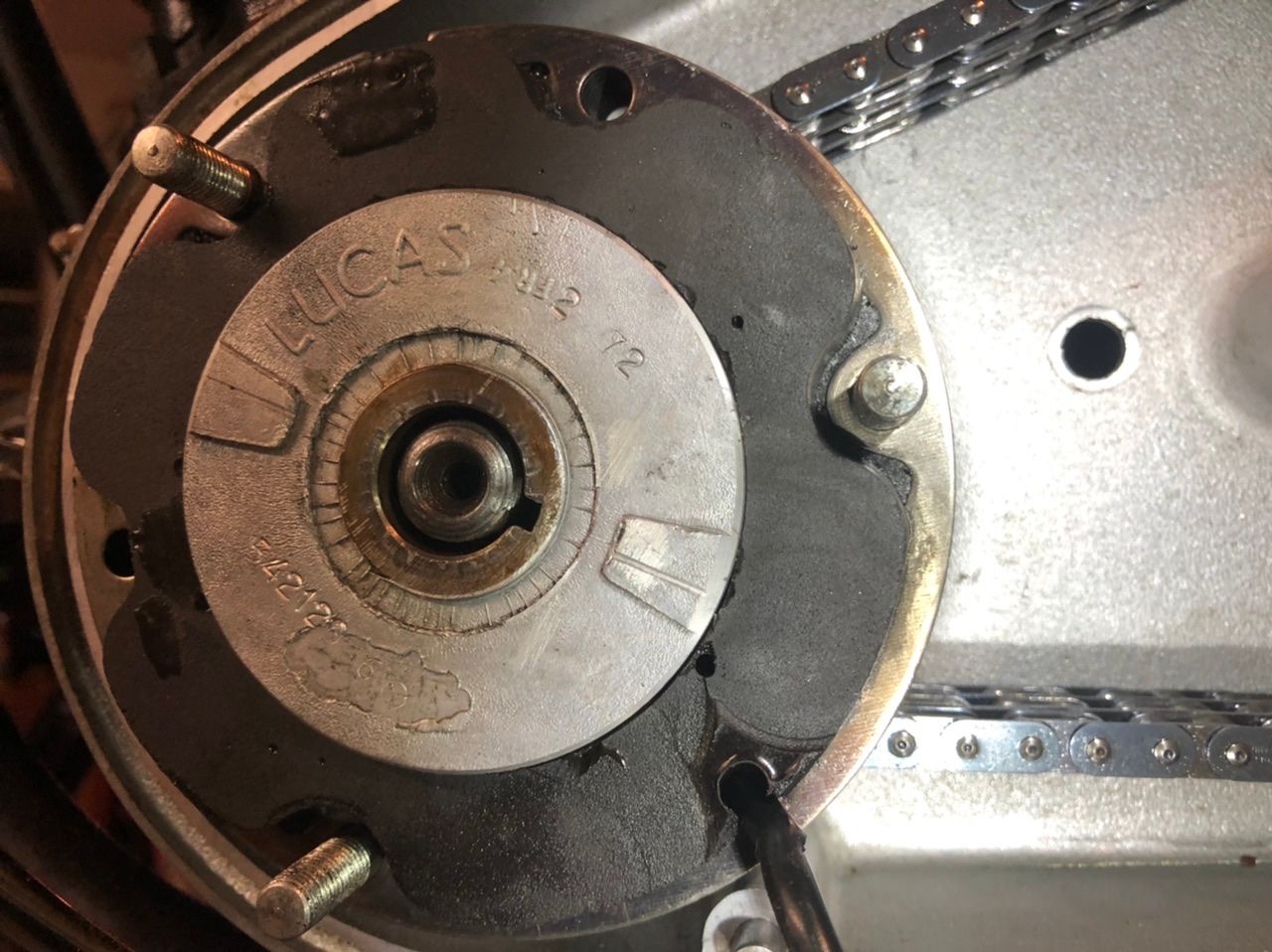

Pictures show my old stator and rotor, which had fit fine, and now won’t fit in the same way the new stator won’t fit. There are no cracks in the chaincase stud mounting bosses, and the studs don’t appear bent. The manual states that if the gap is wrong then the studs must be realigned. how do I do this?

On a positive note, I installed DynoDave’s clutch pushrod seal and it looks great.

Amy help will be most appreciated. Thanks, Ben

Pictures show my old stator and rotor, which had fit fine, and now won’t fit in the same way the new stator won’t fit. There are no cracks in the chaincase stud mounting bosses, and the studs don’t appear bent. The manual states that if the gap is wrong then the studs must be realigned. how do I do this?

On a positive note, I installed DynoDave’s clutch pushrod seal and it looks great.

Amy help will be most appreciated. Thanks, Ben