The late Tony Hayward used the AT10 design as well. I don't think there is anything wrong with the basic design.

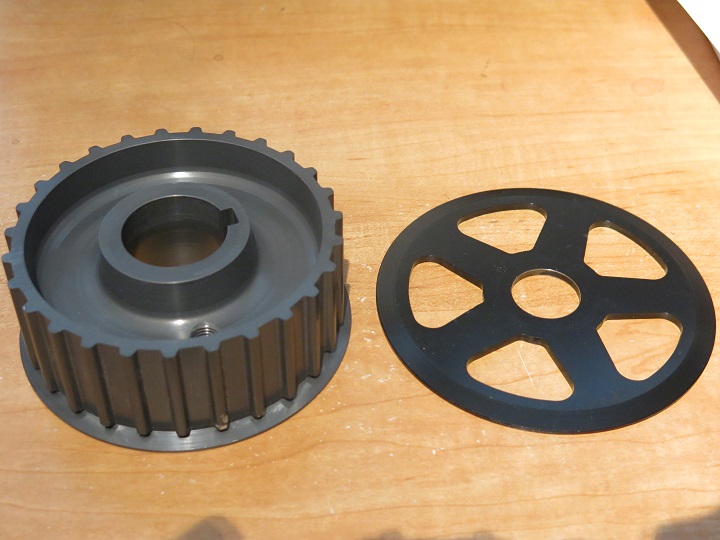

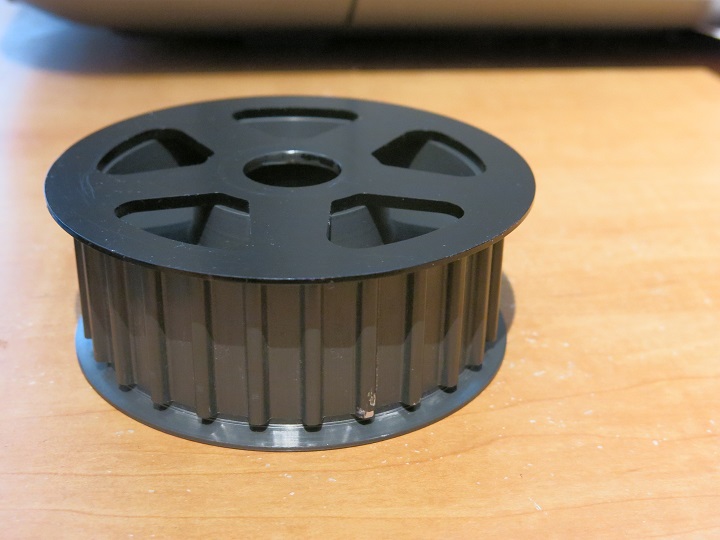

Perhaps, although I think Roger's design using a floppy keeper plate for the engine pulley is a cock-up. Strangely, he offers other pulleys for singles etc. with keeper plates made of steel and fixed by 4 crews on the pulley itself, mirroring the inner keeper plate. Such an arrangement provides much stiffer keeper plates, approaching the stiffness of flanges, so why didn't he make all pulleys like that? A small flange for centralising would make the keeper plate design good.

A rubber belt does not behave on its own - it needs a short run as well as firm guidance, which the engine pulley is supposed to provide, by correct width and stout large flanges. You are moving in the right direction by reducing width of the pulley. I suggest you alter the outer keeper plate design as well, and consider enlarging OD of both keeper plates. Alternatively, have a one-off pulley made with integral flanges, that's what I am looking at.

- Knut