Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 3,663

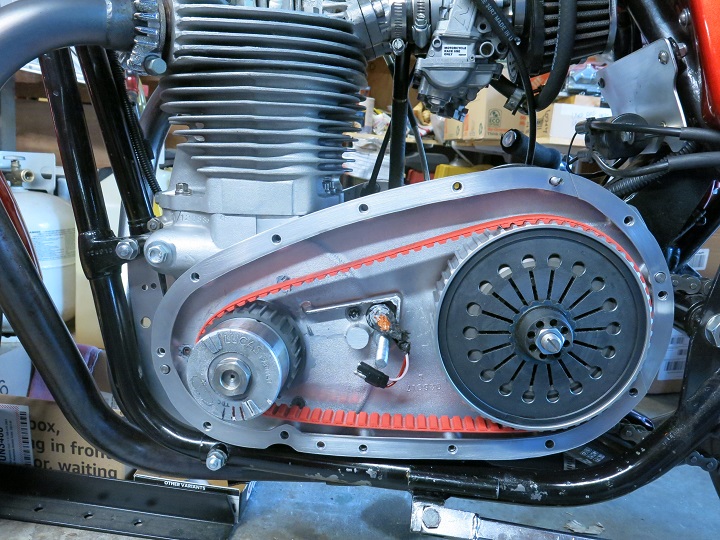

Don't overdo the Dremel grinding on the inside of the clutch dome. I tried to get away with not ordering the 880 belt and make the 890 belt work with the drum in the proper belt adjustment position. Turned a small section of the outer cover into tin foil. What a maroon. It never was a perfect cover anyway.

Pinot Gris and vodka spritzer coming up.

Pinot Gris and vodka spritzer coming up.