You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mk3 chain or belt primary ??

- Thread starter The yaki

- Start date

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 7,731

Does the sprag need oil?You are going to put oil in the primary case? Don't even think about running the primary case dry, the sprag and starter gear train needs oil.

I was told by Alton that the Alton type sprag and chain etc didn't need oil ?

Just wondering if a MK3 does ?

You bet it needs oil! If you run a Mk3 primary without oil you run a big risk of seizing the sprag/starter train, if that happens the least damage it will do is to destroy the starter motor...Does the sprag need oil?

I was told by Alton that the Alton type sprag and chain etc didn't need oil ?

Just wondering if a MK3 does ?

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 7,731

I run a dry belt drive with my Alton starterYou bet it needs oil! If you run a Mk3 primary without oil you run a big risk of seizing the sprag/starter train, if that happens the least damage it will do is to destroy the starter motor...

And even though Alton have said it needs no oil

I still squirt a little into the sprag now and then

The yaki

VIP MEMBER

- Joined

- Feb 7, 2020

- Messages

- 120

I use copperslip on the sprag and it seems to work ok. I have also used oil in it and get a slight leak at the gearbox shaft through primary inner casing as tensioning the belt leaves it off centre. Take your pick ? At least with the belt I'll still have an inner casing !!

A completely different starter system, designed to run dry. With a bendix or pre-engaged starter system, the starter train is disengaged completely from the engine when the engine is running, Not so with the MK3. The sprag revolves around the drive gear and the drive gear has the crankshaft revolving inside it when the engine is running. Your needle roller bearing in the sprag drive gear is going to get very hot, failure is guaranteed. Best outcome a wrecked starter system, worst outcome it throws you off the bike when it seizes.Poser. If you have a car, how often do you take out the starter motor and oil/grease the bendix and lubricate the flywheel ring ??

The chain worn grooves in the bottom of the primary case, caused by a worn primary chain and the engine and gearbox not located properly in the cradle. The standard engine to cradle bolts are just installed in clearance holes. Ditto the g/box, this allows the engine and g/box to move in the cradle. Also the standard g/box studs have the threads too long so allowing the thread to rest against the cradle, making things worse. I bet your inner case showed evidence of the g/box sleeve gear/shaft touching the case adjacent the oil seal. Using fitted bolts/studs in the engine to cradle and g/box mounting, stops them moving around and the primary chain doesn't touch the case. This is one of the improvements outlined in the tuning notes.

The yaki

VIP MEMBER

- Joined

- Feb 7, 2020

- Messages

- 120

I am totally aware of the different starting systems. However it probably depends on usage, milage covered ? And I suppose it would take about 15mins to put oil in, run for 5 mins and drain for those who don't intend touring the continent ?? I did 400+ miles on the copperslip with no adverse results. Also a bullet 500 pre unit belt drive conversion with no problem. Ps, No marks on inner casing, possibly rectified by previous owners. Also what engineer decided to tension a primary outwards ? Possibly why it was the end !!

- Joined

- Dec 28, 2009

- Messages

- 5,278

I run an IWIS duplex from Jason the chain man , in 20 /50 oil , in my MK 111 , never an issue after over 1500 CNW start ups . Enjoy .

- Joined

- Oct 28, 2014

- Messages

- 1,945

I see grooves in the bottom of the primary case. Is that where the chain was run extraordinarily loose? I worked on a MK3 where the chain was run like that and the tensioners were almost ready to pop out of the housing. If that had happened there would have been a disaster

- Joined

- Dec 28, 2009

- Messages

- 5,278

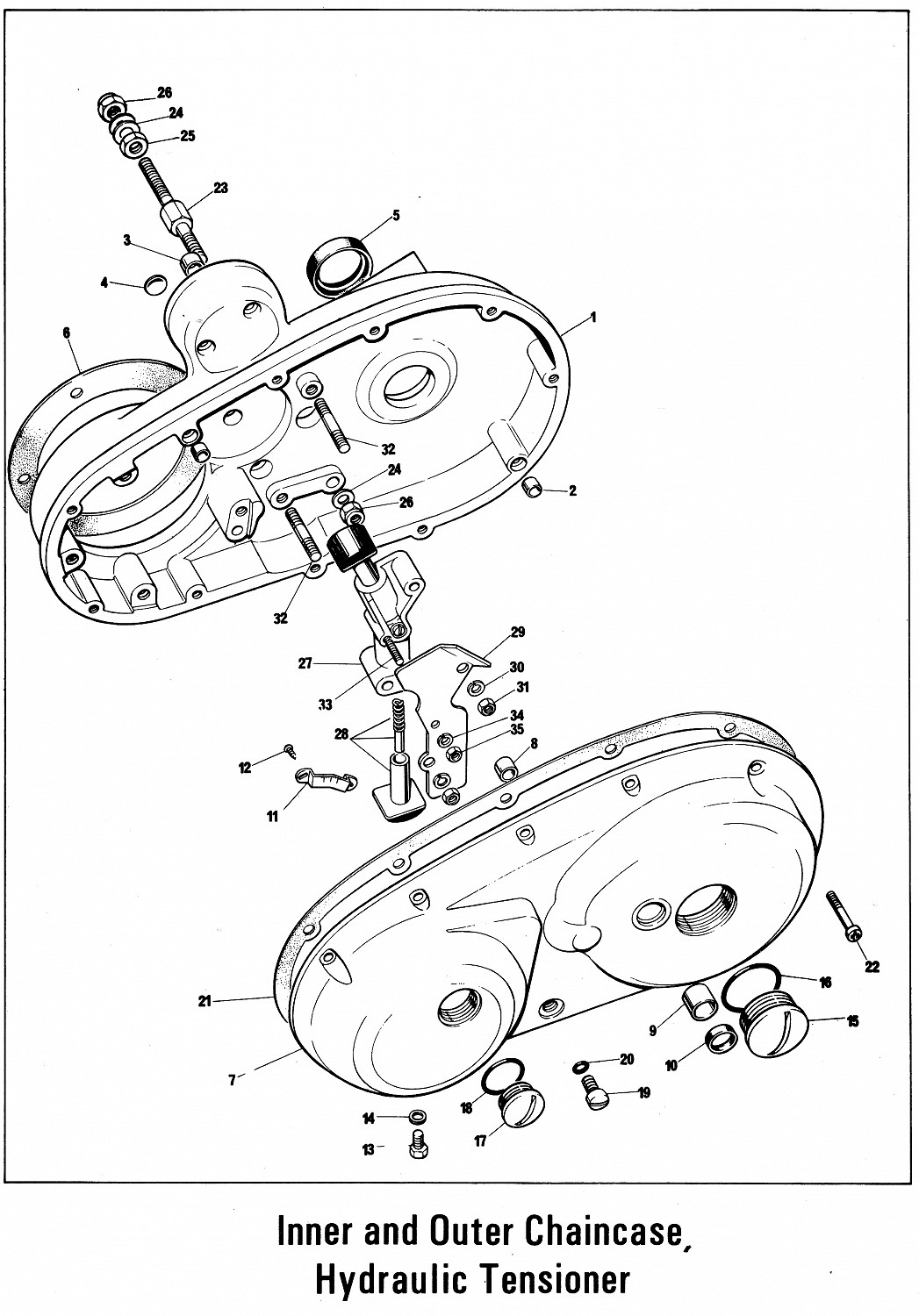

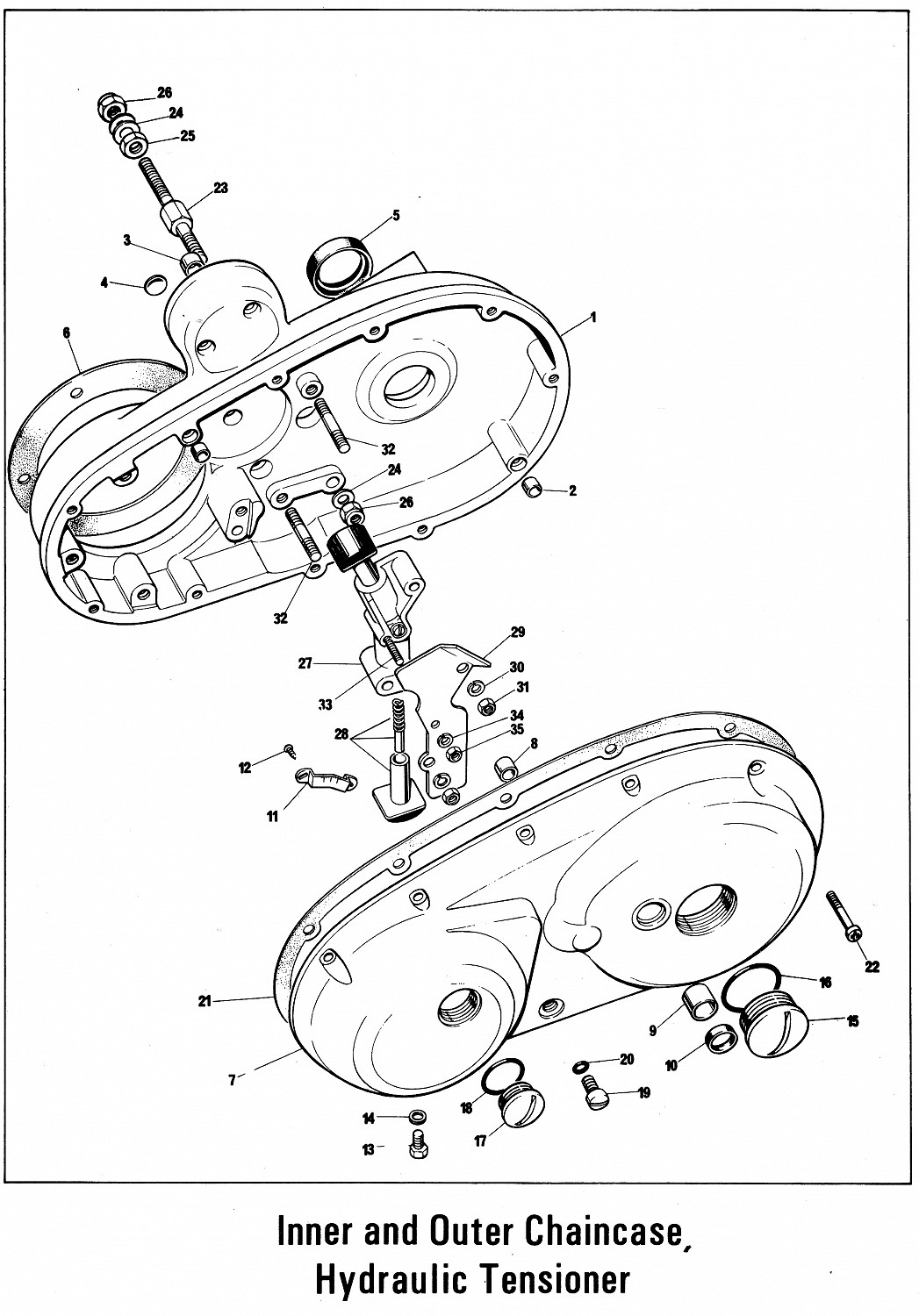

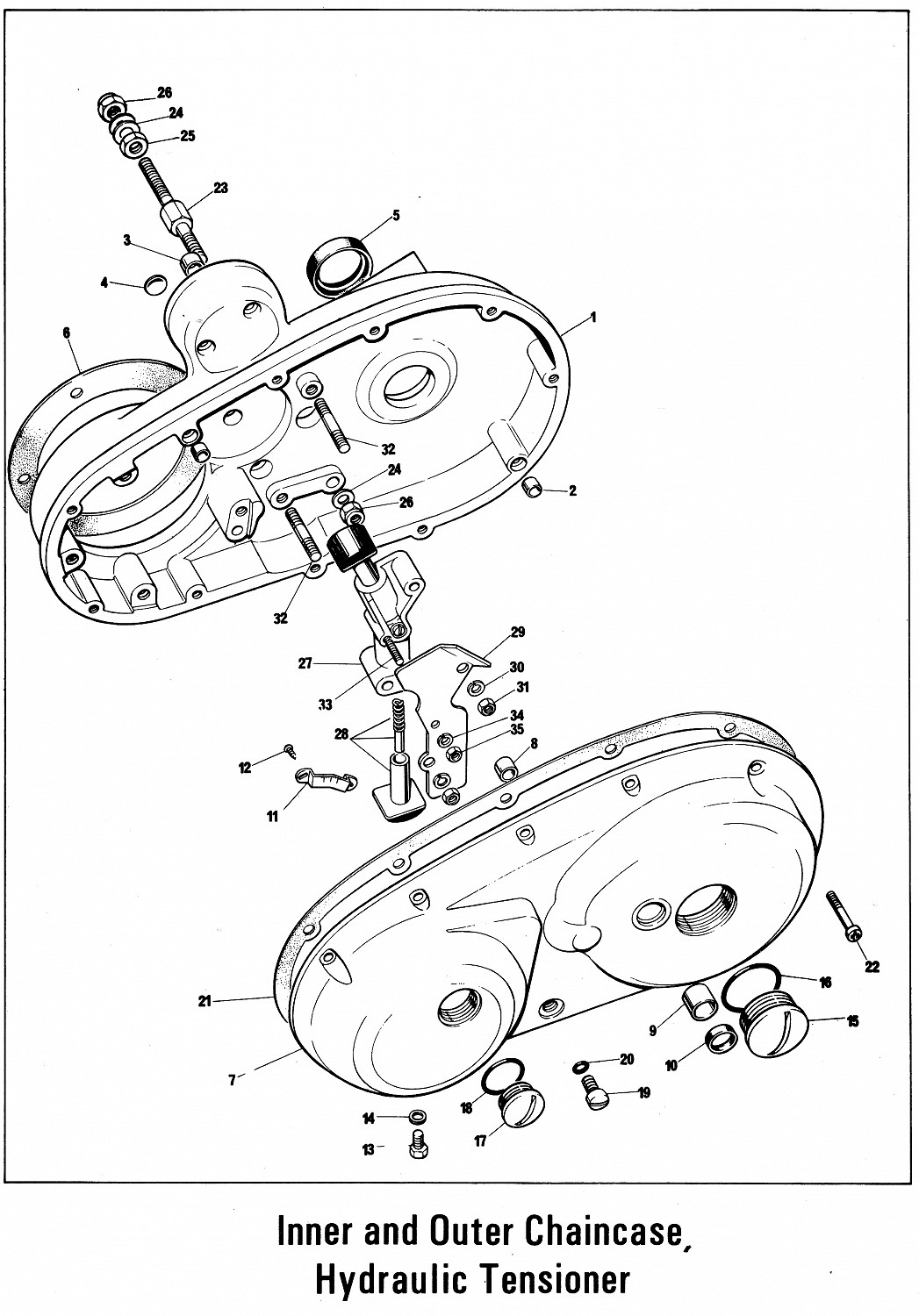

The MK111 hydraulic tensioners parts diagram assembling is wrong . The teflon spring plungers are reversed , up is down .

Mart UK

VIP MEMBER

- Joined

- Mar 11, 2021

- Messages

- 1,258

Not sure I follow. Do you have a link to the diagram?The MK111 hydraulic tensioners parts diagram assembling is wrong . The teflon spring plungers are reversed , up is down .

- Joined

- Dec 28, 2009

- Messages

- 5,278

No . But I have the new revised MK 111 manual , by Charles Kuss ( Chaztuna ) , Myself and other contributors .

The MK 111 primary is complex .

The tensioner body ( 2 of ) requires the nylon pin plunger to fit thick end on to the spring itself . Then press down into the plunger to fit . .

Also the gasket is omitted . You need the thin gasket for the double tensioner body . Omitted in original parts diagrams . 06-6570 .

The MK 111 primary is complex .

The tensioner body ( 2 of ) requires the nylon pin plunger to fit thick end on to the spring itself . Then press down into the plunger to fit . .

Also the gasket is omitted . You need the thin gasket for the double tensioner body . Omitted in original parts diagrams . 06-6570 .

Mart UK

VIP MEMBER

- Joined

- Mar 11, 2021

- Messages

- 1,258

That's understood. I didn't know what you meant by "Teflon spring plungers". I think you mean the white nylon top hat abutment spacers.

The photo of item 28 lower down the page, shows the orientation of the top hat.

The photo of item 28 lower down the page, shows the orientation of the top hat.

This was a source of major failure on my mk3. They were the incorrect way round (by PO). Insufficient chain tension. Chain was grinding lower inner case (grooves several mm deep). Sludge in the oil wore the starter sprag and it failed. Alloy glitter everywhere, in every component in the primary.

Andover Norton Parts Drawings - Genuine Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.

andover-norton.co.uk

This was a source of major failure on my mk3. They were the incorrect way round (by PO). Insufficient chain tension. Chain was grinding lower inner case (grooves several mm deep). Sludge in the oil wore the starter sprag and it failed. Alloy glitter everywhere, in every component in the primary.

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 5,013

Now I'm a little confused. The AN drawing shows 2X of item 28, the plunger and spring and 28 (one each for upper and lower plungers, I assume), but 0X of the 28A abutment spacers. In the photos below, the one for item 28 shows the plunger, spring, and plastic spacer, and item 28A shows just a plastic spacer. The dimensions of the two plastic spacers appear to be significantly different. Why the difference in dimensions for the two plastic spacers? Is the 28A and update design? The factory parts manual just shows item 28 as a set of plunger, spring, and spacer. From that, I'd assume that upper and lower plungers each have the same spring and spacer, but then I don't understand what the AN item 28A is for. Cam someone clarify this for me?That's understood. I didn't know what you meant by "Teflon spring plungers". I think you mean the white nylon top hat abutment spacers.

The photo of item 28 lower down the page, shows the orientation of the top hat.

Andover Norton Parts Drawings - Genuine Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.andover-norton.co.uk

This was a source of major failure on my mk3. They were the incorrect way round (by PO). Insufficient chain tension. Chain was grinding lower inner case (grooves several mm deep). Sludge in the oil wore the starter sprag and it failed. Alloy glitter everywhere, in every component in the primary.

Ken

- Joined

- Nov 20, 2004

- Messages

- 20,260

The AN drawing shows 2X of item 28, the plunger and spring and 28

Correct, two assemblies.

but 0X of the 28A abutment spacers.

The factory parts manual just shows item 28 as a set of plunger, spring, and spacer. From that, I'd assume that upper and lower plungers each have the same spring and spacer, but then I don't understand what the AN item 28A is for. Cam someone clarify this for me?

28a can now be purchased separately. This was not the case originally as there's no 28a in the Mk3 parts book.

The dimensions of the two plastic spacers appear to be significantly different. Why the difference in dimensions for the two plastic spacers?

No, they are the same.

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 5,013

More discussion of clutch issues here:

www.accessnorton.com

www.accessnorton.com

It includes the link below, to a really interesting, if lengthy (127 pages), article on Norton clutches, posted some time back by lister J.M. Leadbeater:.

Ken

heavy clutch/ stack height (2015)

If the gasket you're talking about is the large O-ring, I silicone it into the inner case and put a smear of silicone on the O-ring just before I install the outer cover. Seems to work for me leak free. I believe it is an 850 MkIII, so it would have a conventional gasket instead of the large...

It includes the link below, to a really interesting, if lengthy (127 pages), article on Norton clutches, posted some time back by lister J.M. Leadbeater:.

Ken

Last edited:

Similar threads

- Replies

- 44

- Views

- 2,068

- Replies

- 9

- Views

- 547

- Replies

- 4

- Views

- 209