Ok progress finally. So you dont have to read the whole thread I'll describe the bike and problems. I bought the bike as a beater in 2016, only needed everything, perfect for a project, I did see a running video. I think I paid $3,000

I did a 100% restoration.

I handled every part on the bike, either refinished or replaced. Polishednevery chrome and aluminum part.

1972 Combat Commando. Less than 50 miles since completion.

Cases. superblend bearings,

JS-1 Camshaft.

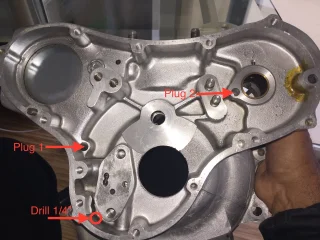

Did the revision on the drive side case to improve the oil flow.

Blocked all the holes from the timing side into the crankcase and drilled a 1/4" hole under the oil pump.

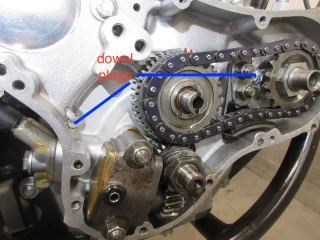

Sent the timing cover to AMR for the Nortec revision and had them rebuild the oil pump.

Comstock reed valve off the back of the case.

Jim Comstock rebuilt the head.

+20 on the JCC pistons with Hastings rings

New Amal premiers 932s middle grove , 220

Last time I ran it the right side was spitting oil out the cam seal @ the Electronic Ignition. Spitting oil out the exhaust port and leaking at the exhaust nut and the header to muffler joint was weeping a lot of oil. I drained the sump and out comes 20oz of oil.

How does a wert dumping condition put oil in the exhaust ports?

So I have pulled the head and taken a lot of pictures.

View attachment 105087