Lineslinger

VIP MEMBER

- Joined

- Feb 26, 2017

- Messages

- 1,790

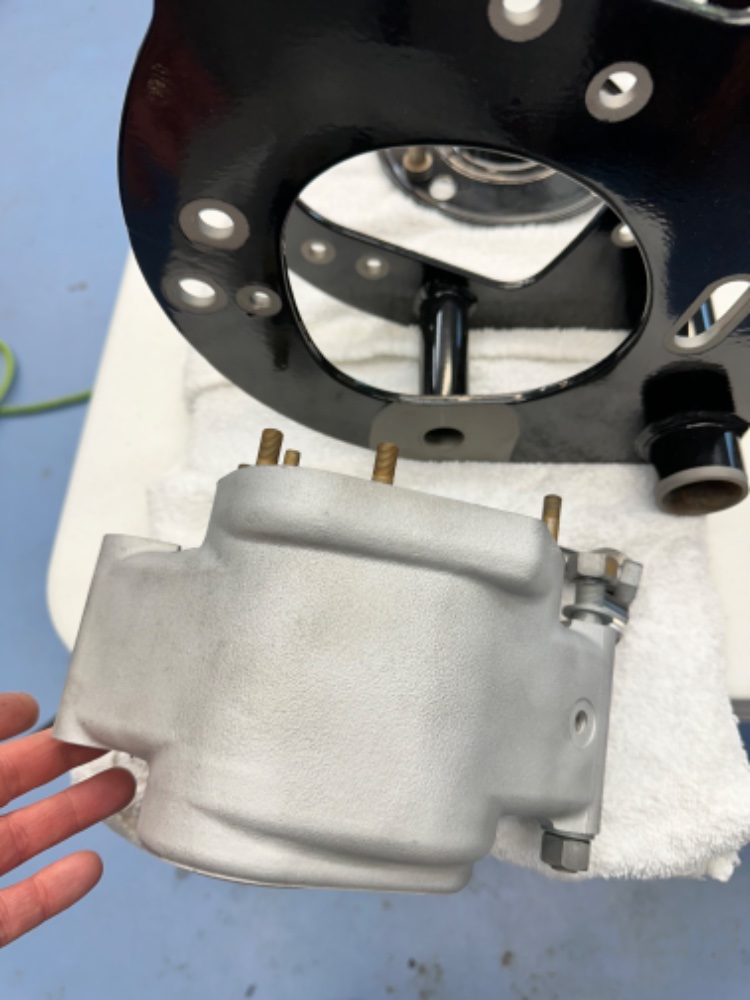

Vapor blasting is a very effective cleanup and leaves an attractive finished appearance. The Amals were Vpr. blasted then the manifolds, bowls and caps went out for powder coating along with a lot of other parts...much like your project appears.

Once I got a look at the finished results of vapor blasting I ended up taking lot of parts to my local shop. I found the cost very forgiving from the perspective of time spent on cleanup and the need for clean fitting/sealing surfaces.

The guys in the shop would come out to the truck and help me haul boxes inside, we were on a first name basis quickly.

Once I got a look at the finished results of vapor blasting I ended up taking lot of parts to my local shop. I found the cost very forgiving from the perspective of time spent on cleanup and the need for clean fitting/sealing surfaces.

The guys in the shop would come out to the truck and help me haul boxes inside, we were on a first name basis quickly.

Last edited: