- Joined

- Jan 7, 2022

- Messages

- 8

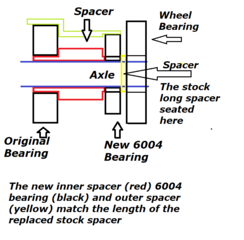

the mk3 two piece axle is 17mm. If you cut the stud off the stud shaft and open it up to 17mm you can insert a one piece axle. I have used the axle from a 1983 kawasaki gpz 750. one must redeuce the length of the shaft and put threads on it for it to fit the swingarm.