New project, but missing VIN plate

- Thread starter GraemeH

- Start date

- Joined

- Feb 18, 2018

- Messages

- 1,323

there are posts elsewhere to show extra holes that can be drilled, like the later crankcases.There is nothing but black paint under the plate on the steering head of a 1971 20M3S Commando so that number has been added after it left the factory.

I did replace the VIN plate but took extra care to save the original for legality purposes.

Only the country legal system will dictate what happens with a new plate added and not having the original at hand.

View attachment 117161

Your engine number is stamped in the concave curve of the case (like mine) so will be March or early April 1971, the number was moved rearward to the flat surface sometime after that time period. (Maybe the guy who could stamp in that previous location retired)

This is the plate for the bike you have with that one only 500 or so after my own March 1971 stamped 1971 Fastback.

View attachment 117160

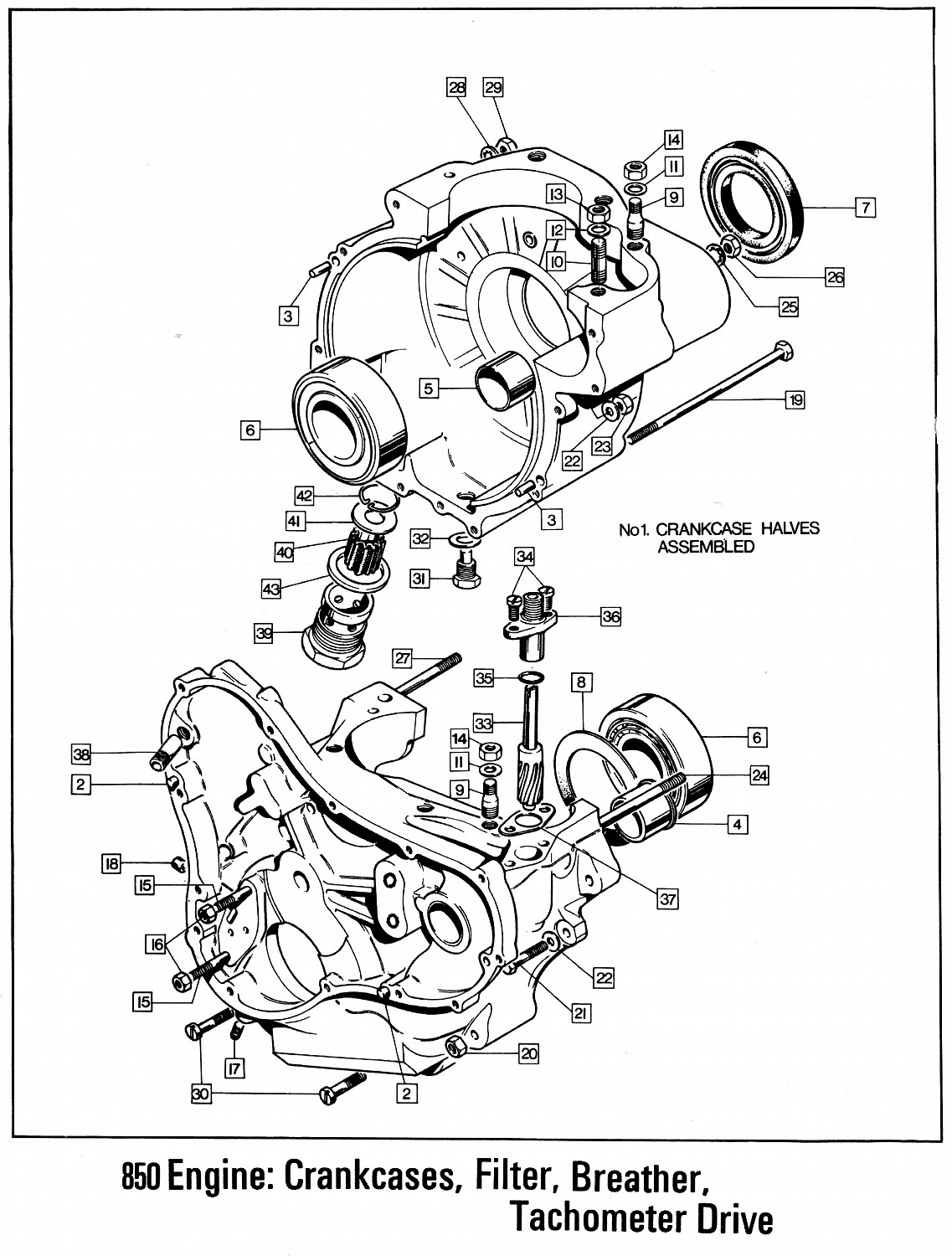

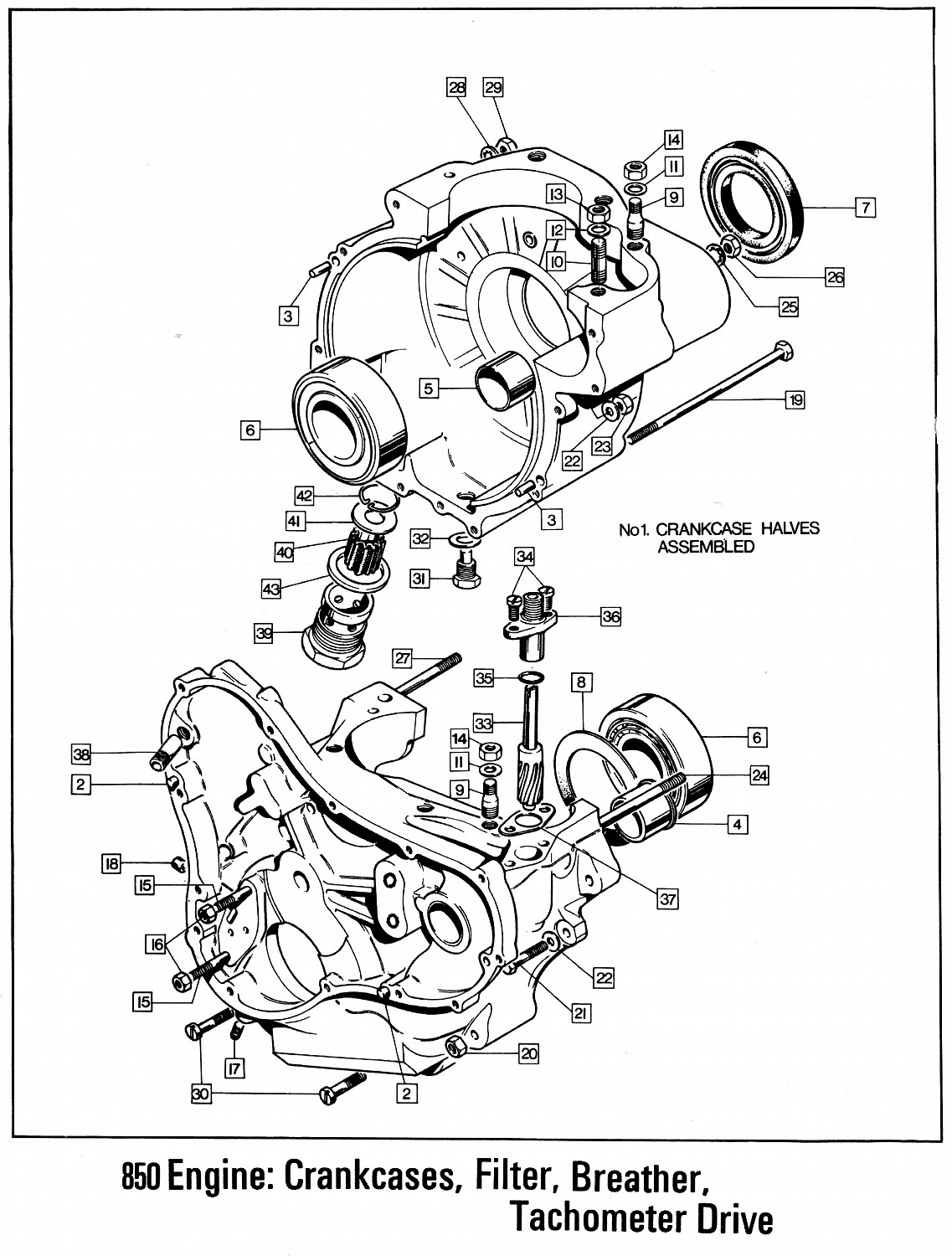

The vent from the location of what would have been the starter motor is fairly pointless as the divider wall is not drilled like the later engines to allow air flow from the central crankcase to the timing chest in any real volume.

The hole highlighted is the only purpose drilling on the camshaft breather 20M3S engine so flow would be restricted unless the case had extra's added for that purpose (venting)

View attachment 117159

- Joined

- Feb 18, 2018

- Messages

- 1,323

I would get expert help for spark plug if possible to avoid extra damage.

- Joined

- Feb 18, 2018

- Messages

- 1,323

I have good barrels( which came to me via northern Italy) if needed.I would get expert help for spark plug if possible to avoid extra damage.

Made some progress in the last couple of days. Head off and cleaned a bit. Got my rocker spindle extractor in the post and put it to good use. I have no clue as to the state of the valve seats and will seek expert advice. Ditto with the spark plug which is still in there.

Struggled with the barrels as the pistons were seriously stuck. I though gravity and WD40 overnight might help:

But came to the conclusion that only heat and violence are useful here. Looks like the piston rings are welded in place:

I won't be using the points again:

Got the timing cover off. Quite a bit of goo in there:

and even a stow-away:

But now I am stuck with the cam shaft nut. The books says to use a cut out timing cover to support it but not everyone has a spare cover to chop up. Will try a bigger lever tomorrow. Any other suggestions?

Cheers

Struggled with the barrels as the pistons were seriously stuck. I though gravity and WD40 overnight might help:

But came to the conclusion that only heat and violence are useful here. Looks like the piston rings are welded in place:

I won't be using the points again:

Got the timing cover off. Quite a bit of goo in there:

and even a stow-away:

But now I am stuck with the cam shaft nut. The books says to use a cut out timing cover to support it but not everyone has a spare cover to chop up. Will try a bigger lever tomorrow. Any other suggestions?

Cheers

- Joined

- Nov 20, 2004

- Messages

- 20,596

The books says to use a cut out timing cover to support it but not everyone has a spare cover to chop up.

Or, use the Andover Norton tool. It's the intermediate spindle that needs to be supported.

Andover Norton - INTERMEDIATE SHAFT SUPPORT PLATE TOOL - 06.7325

INTERMEDIATE SHAFT SUPPORT PLATE TOOL

andover-norton.co.uk

Ah, so this or the cutaway cover only protects the intermediate gear shaft. Do I need to support the camshaft somehow?

Norman White states "It is most important not to shock the camshaft nut into submission... for fear of snapping off the threaded end of the camshaft"

Norman White states "It is most important not to shock the camshaft nut into submission... for fear of snapping off the threaded end of the camshaft"

- Joined

- May 7, 2005

- Messages

- 7,269

Camshaft is already supported by the Crankcase bushes on both ends.Do I need to support the camshaft somehow?

Norman White states "It is most important not to shock the camshaft nut into submission... for fear of snapping off the threaded end of the camshaft"

You tighten the camshaft nut progressively not by hammering on the spanner to the required torque. This is especially important if you have a new cast chilled camshaft where due to the cast iron core it cracks easily, also the cast chilled torque figure for the nut is drastically lower than the factory manual.

So the camshaft nut came off with just a slightly longer lever - an old fork stanchion in this case. Now I have finally for the crank cases apart after buying a grinder to grind down the lips of the special crank pinion extractor tool (why don't they fit from factory?).

Some pics:

Quite dirty in there but no metal noticed

I guess I should replace the camshaft

Some scoring on the cases

Is that right angled cutaway supposed to be there?

Not sure how to get this off. I thought it would be in the crankcase. I only have the flimsy extractor from AN which doesn't fit behind the bearing. Should I just grind the lips thinner so they slip in behind?

Another question - should the intermediate shaft come out? Mine is quite solid. I see a circlip behind it but not sure what the purpose is. I don't see this on the drawings on AN

Some pics:

Quite dirty in there but no metal noticed

I guess I should replace the camshaft

Some scoring on the cases

Is that right angled cutaway supposed to be there?

Not sure how to get this off. I thought it would be in the crankcase. I only have the flimsy extractor from AN which doesn't fit behind the bearing. Should I just grind the lips thinner so they slip in behind?

Another question - should the intermediate shaft come out? Mine is quite solid. I see a circlip behind it but not sure what the purpose is. I don't see this on the drawings on AN

- Joined

- May 7, 2005

- Messages

- 7,269

It's an interference fit at room temperature, if it's tight in its hole and the shaft is not worn leave it be. To remove it take the circlip off, heat the case to 150 C and using a drift drive it out.

To remove the main bearing inners you need knife edged extractors that fit in behind the inner ring.

Note that a random example and you need the correct sized one for the Norton main bearings. Cheap Chinese ones will bend or crack before the bearing inner moves.

To remove the main bearing inners you need knife edged extractors that fit in behind the inner ring.

Note that a random example and you need the correct sized one for the Norton main bearings. Cheap Chinese ones will bend or crack before the bearing inner moves.

Last edited:

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,144

Only if there is a good reason to remove it: Remove the circlip, heat the case to about 200F and push it out from the inside. The circlip keeps it from going further inward - it does not keep it from going outward - the timing cover does that.So the camshaft nut came off with just a slightly longer lever - an old fork stanchion in this case. Now I have finally for the crank cases apart after buying a grinder to grind down the lips of the special crank pinion extractor tool (why don't they fit from factory?).

Some pics:

Quite dirty in there but no metal noticed

View attachment 117393

I guess I should replace the camshaft

View attachment 117392

Some scoring on the cases

Another question - should the intermediate shaft come out? Mine is quite solid. I see a circlip behind it but not sure what the purpose is. I don't see this on the drawings on AN

- Joined

- Nov 20, 2004

- Messages

- 20,596

Is there somewhere else this one will be required?

It's used to remove the engine sprocket (that's what the two long bolts are for).

The short bolts and hooks are used to remove the camshaft sprocket. It isn't intended to be used to extract the crank bearings.

- Joined

- May 7, 2005

- Messages

- 7,269

That would work, note with vapour blasting you will need to clean the cases thoroughly afterwards as even with the grit being within a fluid it will get everywhere and enter joints and holes no matter how well they are masked. I have stopped vapour blasting and now clean in an ultrasonic bath, but one large enough for a crankcase half is expensive.I suppose I need to mask it off before getting it vapour blasted.

An example half in and half out and ran for 20 mins

a finished brakeplate

I still have a question about the main bearing in the photo above - is it broken given that it is not in its surrounding shell in the crankcase? It surely shouldn't be in two parts? All videos I have seen show heating the crank cases to get the complete bearings out.

- Joined

- Nov 20, 2004

- Messages

- 20,596

is it broken given that it is not in its surrounding shell in the crankcase?

No. That's the early roller bearing with the rollers attached to the inner race. If original then it's likely to be marked MRJA30.

It surely shouldn't be in two parts?

Yes, it should even if it's the later type with the rollers attached to the outer race (NJ306E).

Andover Norton - CRANKSHAFT MAIN BEARING (NM17822/4) - 06.4118

CRANKSHAFT MAIN BEARING (NM17822/4)

andover-norton.co.uk

- Joined

- May 7, 2005

- Messages

- 7,269

Roller bearings come in several forms, the one where the rollers is captured in both the inner and outer is not used on Norton's as the bearing is required to float and allow easy assembly and disassembly. Some of these floating type bearings the rollers are either held by the inner or the outer. If, as yours are, the rollers are held by the inner then the rollers stay on the crank, the most common one has the rollers held by the outer leaving the inner ring on the crank and a lot easier to get the knife edge puller behind. You may have to pull the rollers and the cage off to get proper access to the inner.

Page 4 for a better explanation

You have NF and you are best with NJ

Page 4 for a better explanation

You have NF and you are best with NJ

Yes, the roller bearing is MRJA30 made in England.

The ball bearing is Swedish.

I guess none of these are made in Europe any more. Thanks for the doc above - I will now know more than I ever wanted to about bearings .

.

Engine parts now away for cleaning. Now to make a shopping list... more questions will certainly follow.

Thanks all

The ball bearing is Swedish.

I guess none of these are made in Europe any more. Thanks for the doc above - I will now know more than I ever wanted to about bearings

Engine parts now away for cleaning. Now to make a shopping list... more questions will certainly follow.

Thanks all

- Joined

- May 7, 2005

- Messages

- 7,269

The normal way to go is to upgrade to the later twin rollers nicknamed Superblends which will fit all the way back to the 500's. Assembly is much easier if you use the supplied rollers from AN or RGM, they will be FAG bearings made in India.

850 parts, superblend both sides

500 twin model 7 parts with ball on timing side and superblend on driveside

By going two superblend the crank can float from side to side but this has no ill effects.

850 parts, superblend both sides

Andover Norton Parts Drawings - Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.

andover-norton.co.uk

500 twin model 7 parts with ball on timing side and superblend on driveside

Andover Norton Parts Drawings - Genuine Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.

andover-norton.co.uk

By going two superblend the crank can float from side to side but this has no ill effects.