JS exhaust port fillers

- Thread starter Carl H

- Start date

- Joined

- Dec 28, 2009

- Messages

- 5,468

I bought a pair recently and glued them in with high temp copper silicone seal . A very good fit and they are D - floor . Can't say I've noticed much difference in running . MK111 flared pipes mated to 750 silencers .Do these exhaust port fillers make the ports similar to the Fullauto ports?

- Joined

- Nov 26, 2009

- Messages

- 3,254

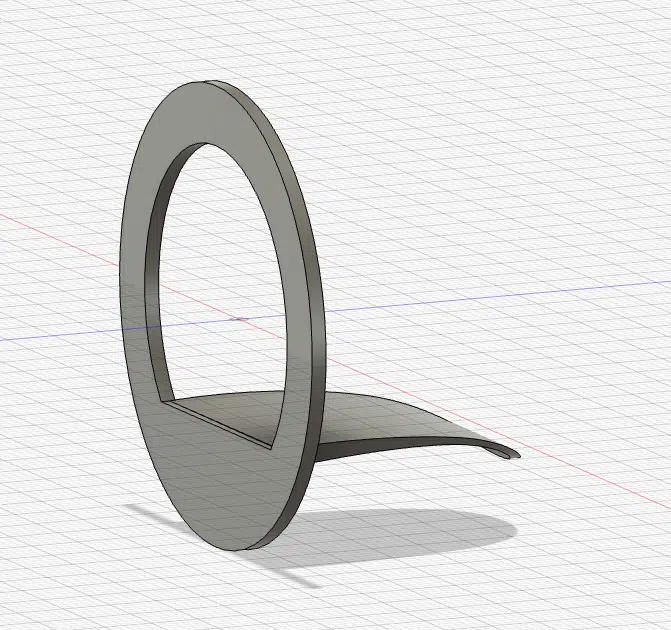

The best shape is the HD XR 750 exhaust port and thats the general shape of the JS ex "Narley" port floor. The point is to present a broad curve on the floor for improved flow.Do these exhaust port fillers make the ports similar to the Fullauto ports?

The air dam at the bottom also helps prevent reversion of slower moving spent gases back into the combustion chamber.

Last edited:

There were many other things also, I put a wire wheel in my Dremel to clean the OD of the exhaust pipes so the mufflers slipped on easier and put some lube on the surface. I had to Dremel the mount holes in the muffler brackets at the holes didn't align. After I got the parts on' I started the bike twice and ran for a few minutes ( my normal warm up procedure) and then retightened the exhaust rose nuts and then I still had to put all the tools away. I probably spent 2 + hours doing it. But knowing the next rides will be better, makes an old race mechanic a happy camper and time flys when your old.That would do it! I had to chase the threads on one of my exhaust ports myself last trip in there. Thankfully I had an old set of 850 roses (I use 750 ones now, with aftermarket non-crossovered pipes) so I was able to cut slots in the threads of one of those to make a tool. It now sits in my "thread tools" box instead of my "Norton parts" box.

- Joined

- Aug 12, 2011

- Messages

- 1,251

When I installed mine all I had to do was to slide the silencers back a little as the inserts push the header pipes a bit forward.No drama.There were many other things also, I put a wire wheel in my Dremel to clean the OD of the exhaust pipes so the mufflers slipped on easier and put some lube on the surface. I had to Dremel the mount holes in the muffler brackets at the holes didn't align. After I got the parts on' I started the bike twice and ran for a few minutes ( my normal warm up procedure) and then retightened the exhaust rose nuts and then I still had to put all the tools away. I probably spent 2 + hours doing it. But knowing the next rides will be better, makes an old race mechanic a happy camper and time flys when your old.

Mike

Do they require an adhesive? There's nothing about that in Jim's instructions. I have a pair sitting on my workbench waiting for winter....I bought a pair recently and glued them in with high temp copper silicone seal . A very good fit and they are D - floor . Can't say I've noticed much difference in running . MK111 flared pipes mated to 750 silencers .

- Joined

- Dec 28, 2009

- Messages

- 5,468

Correct . No sealant/adhesive specified but I smeared some around anyways . I go overboard on the high temp copper at times in the exhaust port threads area . Next time things are off I'll inspect and possibly remove the floors insert sealant .Do they require an adhesive? There's nothing about that in Jim's instructions. I have a pair sitting on my workbench waiting for winter....

I've also got Jim's very thin intake sleeves for my RH4 head and will be carefully tapping them into place using the same silicone sealant , sometime this week .

- Joined

- Oct 28, 2009

- Messages

- 1,365

Sounds like these are available for the Combat head?

Many folks think the Combat heads left the factory in a sorry state, and were further degraded by subsequent well- intentioned but misguided diy tuners.

Will the exhaust port fillers help with this?

Many folks think the Combat heads left the factory in a sorry state, and were further degraded by subsequent well- intentioned but misguided diy tuners.

Will the exhaust port fillers help with this?

Hi Stephen, I was wondering the same thing; I’ve asked Carl - post #10- for info when he tries them in his Combat.Sounds like these are available for the Combat head?

Many folks think the Combat heads left the factory in a sorry state, and were further degraded by subsequent well- intentioned but misguided diy tuners.

Will the exhaust port fillers help with this?

From your post I take it the Combat head “situation” is a generally accepted concept in Canada and the USA (?). Do you know does this originate from?

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,954

Hi Stephen, I was wondering the same thing; I’ve asked Carl - post #10- for info when he tries them in his Combat.

From your post I take it the Combat head “situation” is a generally accepted concept in Canada and the USA (?). Do you know does this originate from?

IIRC the Combat head ‘situation’ is in regard to the inlet port size being too big to be optimal, especially on a 750, and especially with stock valve sizes. By ‘too’ big, I mean big enough such it sacrifices charge velocity, and the extra CFM that should in theory be available, just isn’t able to get past the valve. The smaller port heads have greater velocity, and CFM can be greatly enhanced by careful porting work around the valve throat, and when doing this, many people, like Comnoz, opt to keep the port at the smaller size unless building engines for pure peak hp.

In enlarging the port, the port floor is also lower, creating issues with the charge as it enters the combustion chamber.

The inlet sleeves that JS sells are mainly designed for 850 RH4 heads and reduce the inlet port from 32mm. If they also fit Combat heads (both are 32mm) then I’d imagine it would be a good idea to try them.

None of this means the heads ‘don’t work’. The ‘issue’ is that they’re not optimal.

The exhaust port fillers are a different thing altogether.

Last edited:

FE, thank you. Excellent explanation. Seems a potentially optimal solution is - assuming JS’s fit Combat heads - to fit sleeves and bigger valves.IIRC the Combat head ‘situation’ is in regard to the inlet port size being too big to be optimal, especially on a 750, and especially with stock valve sizes. By ‘too’ big, I mean big enough such it sacrifices charge velocity, and the extra CFM that should in theory be available, just isn’t able to get past the valve. The smaller port heads have greater velocity, and CFM can be greatly enhanced by careful porting work around the valve throat, and when doing this. many people, like Comnoz, opt to keep the port at the smaller size unless building engines for pure peak hp.

In enlarging the port, the port floor is also lower, creating issues with the charge as it enters the combustion chamber.

The inlet sleeves that JS sells are mainly designed for 850 RH4 heads and reduce the inlet port from 32mm. If they also fit Combat heads (both are 32mm) then I’d imagine it would be a good idea to try them.

None of this means the heads ‘don’t work’. The ‘issue’ is that they’re not optimal.

The exhaust port fillers are a different thing altogether.

Of course more power has its associated issues…and ££££ .

Have to say I’m not unhappy with what I have; The usual suspects- PW3 , Paton etc - produce the goods.

Maybe trying out the exhaust port fillers first ; Carl H is heading this route ATM …

- Joined

- Feb 21, 2013

- Messages

- 245

My two combat heads are standard heads ( the early type with 1 1/8” inlet ports ) that had 0.040” shaved of the face and the inlet ports tapered down from 1 1/4”, at the manifold joint, to 1 1/8” at a distance of 2” into the port.

I still don’t know why this is considered ‘too big’. Can someone please explain it?

For the record, my cyl. heads are genuine combats.

I still don’t know why this is considered ‘too big’. Can someone please explain it?

For the record, my cyl. heads are genuine combats.

Mine’s genuine too, late 72 , but don’t know if it’s the same dimensionally as yours…did they change during production cycle ?My two combat heads are standard heads ( the early type with 1 1/8” inlet ports ) that had 0.040” shaved of the face and the inlet ports tapered down from 1 1/4”, at the manifold joint, to 1 1/8” at a distance of 2” into the port.

I still don’t know why this is considered ‘too big’. Can someone please explain it?

For the record, my cyl. heads are genuine combats.

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,954

Jim Comstock did a LOT of testing of inlet port stuff, size of port, whether or not to taper, etc,etc.

It’s all in here, well worth a read…

It’s all in here, well worth a read…

I would like to build up a database of flowtests on modified Norton heads. The tests would be done on one intake port and be from 0 to .450 lift and would include a single velocity measurement measured central in the port 3/4 inch in front of the guide.

If anyone has a modified head setting around that you are curious about and want to get it to me I will test it and pay the return freight. [domestic only] I will post the results here for all to see. It would need to be disassembled and I would need 2 valves. No springs or hardware. Jim

If anyone has a modified head setting around that you are curious about and want to get it to me I will test it and pay the return freight. [domestic only] I will post the results here for all to see. It would need to be disassembled and I would need 2 valves. No springs or hardware. Jim

- comnoz

- Replies: 591

- Forum: Norton Commando Forum

- Joined

- Jul 7, 2009

- Messages

- 189

I think I might try both the intake and exhaust inserts on my newly rebuild combat. This is al interesting to me.IIRC the Combat head ‘situation’ is in regard to the inlet port size being too big to be optimal, especially on a 750, and especially with stock valve sizes. By ‘too’ big, I mean big enough such it sacrifices charge velocity, and the extra CFM that should in theory be available, just isn’t able to get past the valve. The smaller port heads have greater velocity, and CFM can be greatly enhanced by careful porting work around the valve throat, and when doing this, many people, like Comnoz, opt to keep the port at the smaller size unless building engines for pure peak hp.

In enlarging the port, the port floor is also lower, creating issues with the charge as it enters the combustion chamber.

The inlet sleeves that JS sells are mainly designed for 850 RH4 heads and reduce the inlet port from 32mm. If they also fit Combat heads (both are 32mm) then I’d imagine it would be a good idea to try them.

None of this means the heads ‘don’t work’. The ‘issue’ is that they’re not optimal.

The exhaust port fillers are a different thing altogether.

From Atlantic GreenMy two combat heads are standard heads ( the early type with 1 1/8” inlet ports ) that had 0.040” shaved of the face and the inlet ports tapered down from 1 1/4”, at the manifold joint, to 1 1/8” at a distance of 2” into the port.

I still don’t know why this is considered ‘too big’. Can someone please explain it?

For the record, my cyl. heads are genuine combats.

The combat RH3 was cut .042" to raise the compression. It had a 32 mm porting job. It appears the factory learned more about the porting business as time went on. First hand inspection of several "combat" porting jobs show how crudely (bad) they were done. Big.... yes. By today's standards these heads have been ruined. The "BIRCO" on the right and the casting number faintly visible on the left side are negatives (depressions in the surface).

And

"A 73&75 RH4 850 32 mm port head. The porting job out to 32 mm seems to have improved somewhat over the combat. The 850 head types are marked above the right hand exhaust rocker cover. They show a much bigger head gasket pattern compared to all the earlier head styles."

"A 73&75 RH4 850 32 mm port head. The porting job out to 32 mm seems to have improved somewhat over the combat. The 850 head types are marked above the right hand exhaust rocker cover. They show a much bigger head gasket pattern compared to all the earlier head styles."

- Joined

- Feb 21, 2013

- Messages

- 245

Neither of my combat heads are marked “BIRCO” and l’ll read the Jim Comstock posts. The 750 short stroke head re-angled big valves seems to have been copied from the Dunstall big valve head ( or was it the other way round?). Reviewing the factory drawing of the short stroke head the 1 1/4 inlet ports look much the same as those in the earlier 88ss head.

- Joined

- Jun 30, 2012

- Messages

- 14,350

Jim Schmidt's exhaust fillers make sense. Exhaust systems are not so much about flow as they are about resonance. My 2 into 1 system is as smooth as possible when it fits to the head, but I had not thought about the shape where the gas leaves the exhaust valve. The length of my header pipes before the collector are the same length as the tail pipe and muffler after the collector. The resonance frequency of the gas in the tailpipe is always double that of the gas in one of the header pipes. at all revs. And so the tuned lengths are always correct. There is no conflict between sound waves. The pulses in the tail pipe reinforce the pulses in the header pipes.

Most road Commandos probably do not get revved above 5000 RPM, so the exhaust system is not so important.

I run my cam advanced by 12 degrees, so the sound levels are too high.

Most road Commandos probably do not get revved above 5000 RPM, so the exhaust system is not so important.

I run my cam advanced by 12 degrees, so the sound levels are too high.

Last edited:

- Joined

- Dec 28, 2009

- Messages

- 5,468

The same I think too for Combat heads . 32 mm.Neither of my combat heads are marked “BIRCO” and l’ll read the Jim Comstock posts. The 750 short stroke head re-angled big valves seems to have been copied from the Dunstall big valve head ( or was it the other way round?). Reviewing the factory drawing of the short stroke head the 1 1/4 inlet ports look much the same as those in the earlier 88ss head.