You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

fueltap with reserve

- Thread starter mudplugger

- Start date

- Status

- Not open for further replies.

- Joined

- Feb 10, 2009

- Messages

- 3,009

My sums may be "exact" but it's all very approximate in the real world.

But-

A margin of safety is sensible.

Standard old Brit taps and Concentrics are borderline for flow at top speed, in some cases.

But-

A margin of safety is sensible.

Standard old Brit taps and Concentrics are borderline for flow at top speed, in some cases.

- Joined

- May 7, 2005

- Messages

- 7,219

The tunnel is deceptive, as you ride along over bumps etc the fuel moves around enough for it not to help much at all. I ran a TR6 with 2 reserves unknowingly, ran out on what I thought was the main tap and switched to reserve. Reserve took me another 800 yards. Proper main tap with stand tube was installed later that day.

- Joined

- Nov 20, 2004

- Messages

- 20,508

Danno said:Considering the division between the two sides made by the center tube tunnel, a quart or so in the side of the tap with the standpipe can't be accessed. I think I may remove the standpipe. What good is it?

If bike is leant over far enough, the trapped fuel will slosh over to the reserve side so acts as an 'emergency' reserve supply.

As kommando warns, using two 'reserve' taps may not leave very much fuel in reserve.

I'm not running any standpipes for exactly Danno's reasoning. The roadster tank does give a measure of reserve because of the division, about a US pint or so, not much but it's something. If I run out of gas I will say to my self "I'M AN IDIOT". not "I wish I had a reserve".

As far as leaning the bike over and shaking it to access the fuel trapped on the standpipe side after you've once AGAIN run out of fuel,,, come on now what's this called, reserve, reserve? Three gallons is three gallons. Two Nortons that get the same mileage, side by side, going down that long desert hi-way, are going to run out of gas at the same point whether one has a standpipe or not. Only difference is the rider with "reserve" would have spent some time shaking his bike back and forth to get all his gas. Both riders "reserve" will be in a gas can in the bed of that pick-up truck that eventually comes along.

"What the matter, you boys run outta gas".

As far as leaning the bike over and shaking it to access the fuel trapped on the standpipe side after you've once AGAIN run out of fuel,,, come on now what's this called, reserve, reserve? Three gallons is three gallons. Two Nortons that get the same mileage, side by side, going down that long desert hi-way, are going to run out of gas at the same point whether one has a standpipe or not. Only difference is the rider with "reserve" would have spent some time shaking his bike back and forth to get all his gas. Both riders "reserve" will be in a gas can in the bed of that pick-up truck that eventually comes along.

"What the matter, you boys run outta gas".

- Joined

- Nov 20, 2004

- Messages

- 20,508

Biscuit said:Three gallons is three gallons. Two Nortons that get the same mileage, side by side, going down that long desert hi-way, are going to run out of gas at the same point whether one has a standpipe or not. Only difference is the rider with "reserve" would have spent some time shaking his bike back and forth to get all his gas. Both riders "reserve" will be in a gas can in the bed of that pick-up truck that eventually comes along.

We don't all ride desert highways. Running completely out of fuel on a busy British road can be hazardous due to the narrow width and sometimes there's nowhere to pull off the roadway, as for pickup trucks (not common in the UK) or anyone else stopping to offer petrol it's less likely here, so I'd rather keep the standpipe and have the chance to fill up sooner.

- Joined

- Feb 7, 2010

- Messages

- 4,195

With the SS/Hi-Rider tank, I don't figure on going more than 100 miles without fueling up in any case. Yesterday I drained the reserve (left) side to replace a sealing washer and there was still a bit of fuel on the right (main) side. I might do some experimenting while carrying a small container of fuel just to see what works how.

L.A.B. said:We don't all ride desert highways. Running completely out of fuel on a busy British road can be hazardous due to the narrow width and sometimes there's nowhere to pull off the roadway, as for pickup trucks (not common in the UK) or anyone else stopping to offer petrol it's less likely here, so I'd rather keep the standpipe and have the chance to fill up sooner.

The "desert highway" thing was kind of a metaphor. My point was, "out of gas is out of gas". Reserve does not get you more gas any more than hiding money in a book gets you extra cash. Reserve is in your head, not your tank.

Onder

VIP MEMBER

- Joined

- May 11, 2010

- Messages

- 4,285

Im in the run two reserve taps camp. Use the odometer to tell you when to take fuel. In the rural areas

now (USA) there are fewer filling stations so pay attention and plan your ride. Never hurts to top off

when you can.

Another reason to move to an Interstate tank.

now (USA) there are fewer filling stations so pay attention and plan your ride. Never hurts to top off

when you can.

Another reason to move to an Interstate tank.

The reserve setup certainly has saved my bacon a few times when out on tour. Admittedly with the Interestate it tends to be less of a problem , but with the Vincent tank at just 3 3/4 Imperial gallons, I find reserve gas to be very useful.

A 3 3/4 gallon tankful generally gets you down the road about 180 miles or so but sometimes, with a big headwind or heavy load in mountainous terrain, or both, range is reduced to 125 miles or so. I never really know exactly what the range will be. Sometimes you are climbing a lot and it doesn't feel like it. Sometimes that head wind is stronger than you realize.

So the fuel runs out and the engine goes onto the rear cylinder ( lower Carb). While rolling along I reach down and open the reserve tap (3 position type to suck out all fuel) and make it to the next town which I wasn't planning on stopping at.

The reserve has informed me that I'm nearly out of fuel much earlier than planned. Without a reserve I would have run out of fuel about twenty miles past the crappy little gas station I did not want to stop at, but still ten miles from the lovely new Chevron station of my dreams.

The gas from the crappy little station works just fine, much better than no gas, no cell phone reception ( mountains) and pushing ten miles in the mountains. Always in the mountains.

I like reserve. Twenty mile size is nice.

Glen

A 3 3/4 gallon tankful generally gets you down the road about 180 miles or so but sometimes, with a big headwind or heavy load in mountainous terrain, or both, range is reduced to 125 miles or so. I never really know exactly what the range will be. Sometimes you are climbing a lot and it doesn't feel like it. Sometimes that head wind is stronger than you realize.

So the fuel runs out and the engine goes onto the rear cylinder ( lower Carb). While rolling along I reach down and open the reserve tap (3 position type to suck out all fuel) and make it to the next town which I wasn't planning on stopping at.

The reserve has informed me that I'm nearly out of fuel much earlier than planned. Without a reserve I would have run out of fuel about twenty miles past the crappy little gas station I did not want to stop at, but still ten miles from the lovely new Chevron station of my dreams.

The gas from the crappy little station works just fine, much better than no gas, no cell phone reception ( mountains) and pushing ten miles in the mountains. Always in the mountains.

I like reserve. Twenty mile size is nice.

Glen

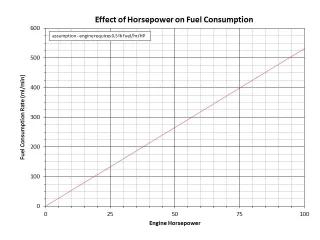

I believe the reality and bottom line to the discussion of fuel consumption rate was articulated correctly by TritonThrasher, as it is well accepted that air cooled naturally aspirated (NA) engines require ~ 0.5 lb fuel/hr/hp, thus for any HP engine we can easily calculate the fuel consumption rate as Triton did. I used Triton’s number (266 ml/min for 50 HP) to create the plot below that should cover the majority of NA iterations of our engines.

Using a fuel density of 0.75 g/ml (in reality could be anywhere from 0.71 to 0.77 g/ml), the HP numbers provided below, and assuming all gallons were Imperial, the examples given by Leadbeater and Eddie were subject to calculation to see how they compared to the oft cited 0.5 lb fuel/hr/hp.

Leadbeater’s example was very close to Triton's number coming in at 0.6 lb fuel/hr/hp (assumed a 50 HP engine). Eddie's example also required a HP value to get back to a fuel consumption rate and in this case I arbitrarily chose a 65 HP engine (reasoning that his 840 cc Triton racing rig was somewhat better than a stock 50 HP Norton). Eddie’s 12 mpg example consumed ~ 2X more fuel than Leadbeater, coming in at a fuel consumption rate of 1.16 lb/hr/hp.

Using a fuel density of 0.75 g/ml (in reality could be anywhere from 0.71 to 0.77 g/ml), the HP numbers provided below, and assuming all gallons were Imperial, the examples given by Leadbeater and Eddie were subject to calculation to see how they compared to the oft cited 0.5 lb fuel/hr/hp.

Leadbeater’s example was very close to Triton's number coming in at 0.6 lb fuel/hr/hp (assumed a 50 HP engine). Eddie's example also required a HP value to get back to a fuel consumption rate and in this case I arbitrarily chose a 65 HP engine (reasoning that his 840 cc Triton racing rig was somewhat better than a stock 50 HP Norton). Eddie’s 12 mpg example consumed ~ 2X more fuel than Leadbeater, coming in at a fuel consumption rate of 1.16 lb/hr/hp.

Attachments

texasSlick

VIP MEMBER

- Joined

- Jan 2, 2013

- Messages

- 4,258

The fuel consumption rates Fast Eddie. JM Leadbeater, and I were attempting to calculate, or at least estimate, was for MAXIMUM RPM AND SUSTAINED MAXIMUM POWER OUTPUT. We each expressed concerns that fuel taps could not deliver the required fuel rates.

I dusted off some old textbooks and did some research on specific fuel consumption rates (sfcr). The following Figures are from 1960's textbooks, so the data is representative of the period of our Norton engines. Modern engines with computer controlled fuel injection, ignition timing, and variable cam timing are not to be compared to this data.

The first thing to notice, is the value of sfcr for a typical (all engines in such data sheets should be considered typical, unless a footnote declares otherwise) gasoline engine. There, in the first line of the data, is that value of 0.5 lb/hr/hp that Triton Thrasher used in his computations, and that WZ507 used for his graph above. But there is a big rub ... take notice of note (b), which tells us the value is taken at maximum thermal efficiency. Now review Fig 2, and note that the sfcr curve (high-lighted in yellow, and scale read at right), is not constant, but has a minimum at the maximum thermal efficiency rpm. This rpm corresponds to the maximum torque point as well. Auto designers gear the vehicle so this maximum thermal, and minimum sfcr, rpm corresponds to typical highway cruise speeds. Note further, that the value of sfcr increases by about 17% from the minimum for this engine, peaking out at the maximum rated rpm which is a modest 4400 rpm (this is an engine for economy, not performance).

Specific fuel consumption rises with increasing rpm mainly due to increased internal friction of the engine. For a high performance, high revving engine, we should expect sfcr to increase by a greater amount than that shown in Fig 2.

Note, in Fig 1, the values of sfcr for an aircraft engine. Note (c) tells us the value is at maximum efficiency, while note (d) indicates the value is at maximum (but not take-off) power. (In an aircraft, maximum power is the maximum sustained cruise power, while the engine can deliver more power for take-off but such higher power is limited to a 5 minute burst only). The sfcr increases by a whopping 59% from max efficiency to max power! You can bet take-off power will increase the sfcr even more.

One more point to consider: the data is for typical engines, the engine of Fig 2 develops 0.67 hp/cubic inch displacement, the Lycoming aircraft engine which powers the ubiquitous Cessna 172 develops 0.5 hp/ci. Our Nortons develop 1.3 hp/ci. Higher performance engine have higher sfcr.

Fig 1

Fig 2

Triton Thrasher's calculations and WZ507 's graph are 100% accurate, but are appropriate ONLY for cruise conditions, which is the rpm range that the value of 0.5 applies. From a strictly technical standpoint, the performance data such as Fig 2 are developed at WOT, and since no one cruises at WOT, the value of the chart is moot.

To accurately determine the minimum fuel delivery rate that a petrol tap must deliver for SUSTAINED MAXIMUM POWER, we must have a performance chart for our Norton engines similar to Fig. 2, and we must use the value of sfcr that is found to occur AT THE MAXIMUM POWER RPM. A dyno run will not suffice for the performance chart we need, unless the instantaneous fuel consumption rate is simultaneously measured while the hp vs rpm chart is developed.

In lieu of a proper performance chart for a Norton engine, we can only "guesstimate" a reasonable value of sfcr at max. rpm and power. I would say 0.8 to 1.0 is reasonable ... admittedly, this is a "gut" estimate, but from the discussion above, it should be accepted that 0.5 does not apply. Using 0.8, I calculate a required fuel delivery rate of 0.9 US pints per minute (426 ml/min), while sfcr of 1.0 requires 1.12 US pints per minute (530 ml/min). These numbers are based on a 60 hp engine, apply proportional calculation for other hp ratings.

htown16 quoted a source who stated 300 ml/min FOR EACH FLOAT was the minimum with sufficient reserve. That is 600 ml/min total, or 1.26 US pints per minute. That latter value corresponds to Fast Eddie's and my own initial estimate.

I would like to hear from the racers and speed trials guys .... how are you ensuring adequate fuel flow?

For now, it seems like the guys who are running dual petrol taps feeding dual concentrics with dual floats and needles, have an advantage over us with sawed off Monoblocs sharing one float and needle.

Slick

I dusted off some old textbooks and did some research on specific fuel consumption rates (sfcr). The following Figures are from 1960's textbooks, so the data is representative of the period of our Norton engines. Modern engines with computer controlled fuel injection, ignition timing, and variable cam timing are not to be compared to this data.

The first thing to notice, is the value of sfcr for a typical (all engines in such data sheets should be considered typical, unless a footnote declares otherwise) gasoline engine. There, in the first line of the data, is that value of 0.5 lb/hr/hp that Triton Thrasher used in his computations, and that WZ507 used for his graph above. But there is a big rub ... take notice of note (b), which tells us the value is taken at maximum thermal efficiency. Now review Fig 2, and note that the sfcr curve (high-lighted in yellow, and scale read at right), is not constant, but has a minimum at the maximum thermal efficiency rpm. This rpm corresponds to the maximum torque point as well. Auto designers gear the vehicle so this maximum thermal, and minimum sfcr, rpm corresponds to typical highway cruise speeds. Note further, that the value of sfcr increases by about 17% from the minimum for this engine, peaking out at the maximum rated rpm which is a modest 4400 rpm (this is an engine for economy, not performance).

Specific fuel consumption rises with increasing rpm mainly due to increased internal friction of the engine. For a high performance, high revving engine, we should expect sfcr to increase by a greater amount than that shown in Fig 2.

Note, in Fig 1, the values of sfcr for an aircraft engine. Note (c) tells us the value is at maximum efficiency, while note (d) indicates the value is at maximum (but not take-off) power. (In an aircraft, maximum power is the maximum sustained cruise power, while the engine can deliver more power for take-off but such higher power is limited to a 5 minute burst only). The sfcr increases by a whopping 59% from max efficiency to max power! You can bet take-off power will increase the sfcr even more.

One more point to consider: the data is for typical engines, the engine of Fig 2 develops 0.67 hp/cubic inch displacement, the Lycoming aircraft engine which powers the ubiquitous Cessna 172 develops 0.5 hp/ci. Our Nortons develop 1.3 hp/ci. Higher performance engine have higher sfcr.

Fig 1

Fig 2

Triton Thrasher's calculations and WZ507 's graph are 100% accurate, but are appropriate ONLY for cruise conditions, which is the rpm range that the value of 0.5 applies. From a strictly technical standpoint, the performance data such as Fig 2 are developed at WOT, and since no one cruises at WOT, the value of the chart is moot.

To accurately determine the minimum fuel delivery rate that a petrol tap must deliver for SUSTAINED MAXIMUM POWER, we must have a performance chart for our Norton engines similar to Fig. 2, and we must use the value of sfcr that is found to occur AT THE MAXIMUM POWER RPM. A dyno run will not suffice for the performance chart we need, unless the instantaneous fuel consumption rate is simultaneously measured while the hp vs rpm chart is developed.

In lieu of a proper performance chart for a Norton engine, we can only "guesstimate" a reasonable value of sfcr at max. rpm and power. I would say 0.8 to 1.0 is reasonable ... admittedly, this is a "gut" estimate, but from the discussion above, it should be accepted that 0.5 does not apply. Using 0.8, I calculate a required fuel delivery rate of 0.9 US pints per minute (426 ml/min), while sfcr of 1.0 requires 1.12 US pints per minute (530 ml/min). These numbers are based on a 60 hp engine, apply proportional calculation for other hp ratings.

htown16 quoted a source who stated 300 ml/min FOR EACH FLOAT was the minimum with sufficient reserve. That is 600 ml/min total, or 1.26 US pints per minute. That latter value corresponds to Fast Eddie's and my own initial estimate.

I would like to hear from the racers and speed trials guys .... how are you ensuring adequate fuel flow?

For now, it seems like the guys who are running dual petrol taps feeding dual concentrics with dual floats and needles, have an advantage over us with sawed off Monoblocs sharing one float and needle.

Slick

Last edited:

In the sixties, the Harley flat trackers experienced fuel starvation problems due to fuel taps. The Pingel fuel tap was designed to eliminated that problem.

I used a pair of them on my Special.

They are a bit pricey, but have a very high flow rate. Pingel has a 3 position reserve tap that will drain all of the fuel out.

They also have solenoid operated taps if you would like the fuel to automatically shut off and on with the ignition.

http://www.pingelonline.com/prodcat/fuel-valves.asp

Glen

I used a pair of them on my Special.

They are a bit pricey, but have a very high flow rate. Pingel has a 3 position reserve tap that will drain all of the fuel out.

They also have solenoid operated taps if you would like the fuel to automatically shut off and on with the ignition.

http://www.pingelonline.com/prodcat/fuel-valves.asp

Glen

- Joined

- Feb 10, 2009

- Messages

- 3,009

Texasslick-

Interesting that the aero engine at max power is quoted at 0.67 lb/hp/hr. That looks more realistic than the 0.5 I used.

I also don't know how the efficiency of a Norton at max output compares to an aero engine. Aero stuff is generally better engineered.

Interesting that the aero engine at max power is quoted at 0.67 lb/hp/hr. That looks more realistic than the 0.5 I used.

I also don't know how the efficiency of a Norton at max output compares to an aero engine. Aero stuff is generally better engineered.

texasSlick

VIP MEMBER

- Joined

- Jan 2, 2013

- Messages

- 4,258

I have made some flow measurements on an Ewarts fuel tap. As this type tap was used on the Atlas, I will post results in the "Other Nortons" forum.

The results are interesting, and should be informative to all, regardless of fuel taps being used.

Slick

The results are interesting, and should be informative to all, regardless of fuel taps being used.

Slick

- Joined

- Nov 11, 2013

- Messages

- 5,403

texasSlick said:htown16 quoted a source who stated 300 ml/min FOR EACH FLOAT was the minimum with sufficient reserve. That is 600 ml/min total, or 1.26 US pints per minute. That latter value corresponds to Fast Eddie's and my own initial estimate.

Is this really right, since a cylinder only sucks fuel every other rotation, and only one carb is actively sucking at a time, wouldn't the constant rate for the entire engine be 300m/l?

texasSlick

VIP MEMBER

- Joined

- Jan 2, 2013

- Messages

- 4,258

gortnipper said:texasSlick said:htown16 quoted a source who stated 300 ml/min FOR EACH FLOAT was the minimum with sufficient reserve. That is 600 ml/min total, or 1.26 US pints per minute. That latter value corresponds to Fast Eddie's and my own initial estimate.

Is this really right, since a cylinder only sucks fuel every other rotation, and only one carb is actively sucking at a time, wouldn't the constant rate for the entire engine be 300m/l?

I interpreted the source was recommending 300 ml/min as minimum fuel delivery rate to each carb. That would be the amount each carb could swallow in a minute, leaving some for reserve. Of course, engine size and horsepower enter into this. IMO, 600 ml/min is not excessive for a 60 plus hp engine, but smaller hp and displacement engines will not require as much. Perhaps htown16 can tell us the engine displacement his source was using.

I have just posted fuel delivery rates for the tap on my Atlas over in the "Other Norton's" forum. My Atlas tap can deliver nearly 700 ml/min. if Main and Reserve are turned on simultaneously.

Slick

Ok so i just went into garage an tried measuring flow. Half full roadster tank with two reserve type taps to get every last drop if needs be. Twin Amal Premier carbs with float drain plugs removed.

1tap on 1 carb flows 200ml per minute

1tap on 2 carbs flow 300ml per minute

2taps on 2 carbs flow 400ml per minute

The bike will hold 70mph about 4000rpm all day or 80mph but on motorway its me that gets bored not the bike. It will also go to the ton and stay there but normally you run out of space or my license starts to panic (i have nearly lost it in the past an that would be far to life changing)

So given the way the bike runs and way i ride it i believe i should not worry (unless you think otherwise) and i guess many other owners have same performance.

So my point is really how long do you need to hold max power of flow to be an issue? An if it doesn't seem at any rate to be an issue is it an issue?

1tap on 1 carb flows 200ml per minute

1tap on 2 carbs flow 300ml per minute

2taps on 2 carbs flow 400ml per minute

The bike will hold 70mph about 4000rpm all day or 80mph but on motorway its me that gets bored not the bike. It will also go to the ton and stay there but normally you run out of space or my license starts to panic (i have nearly lost it in the past an that would be far to life changing)

So given the way the bike runs and way i ride it i believe i should not worry (unless you think otherwise) and i guess many other owners have same performance.

So my point is really how long do you need to hold max power of flow to be an issue? An if it doesn't seem at any rate to be an issue is it an issue?

htown16

VIP MEMBER

- Joined

- Apr 29, 2009

- Messages

- 1,527

The figure I quoted, 300 ml/min per carb was from a fellow that posted on Triumph bulletin boards. His handle was Mr Pete and he was from Australia. He was one of those guys who's opinion was widely respected based on his extensive background working on old bikes. I'm assuming he was mainly referring to 650 Triumphs, but the hp difference between them and Commando's is probably insignificant.

He stated that the 300 ml/min per carb was twice what was required, but because you were measuring max flow with the float sitting in the bottom of the bowl it was a safe margin. Here's a link to the original post. His is the 4th post down.

http://www.triumphrat.net/classic-vinta ... -taps.html

He stated that the 300 ml/min per carb was twice what was required, but because you were measuring max flow with the float sitting in the bottom of the bowl it was a safe margin. Here's a link to the original post. His is the 4th post down.

http://www.triumphrat.net/classic-vinta ... -taps.html

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,784

WZ507 said:I believe the reality and bottom line to the discussion of fuel consumption rate was articulated correctly by TritonThrasher, as it is well accepted that air cooled naturally aspirated (NA) engines require ~ 0.5 lb fuel/hr/hp, thus for any HP engine we can easily calculate the fuel consumption rate as Triton did. I used Triton’s number (266 ml/min for 50 HP) to create the plot below that should cover the majority of NA iterations of our engines.

Using a fuel density of 0.75 g/ml (in reality could be anywhere from 0.71 to 0.77 g/ml), the HP numbers provided below, and assuming all gallons were Imperial, the examples given by Leadbeater and Eddie were subject to calculation to see how they compared to the oft cited 0.5 lb fuel/hr/hp.

Leadbeater’s example was very close to Triton's number coming in at 0.6 lb fuel/hr/hp (assumed a 50 HP engine). Eddie's example also required a HP value to get back to a fuel consumption rate and in this case I arbitrarily chose a 65 HP engine (reasoning that his 840 cc Triton racing rig was somewhat better than a stock 50 HP Norton). Eddie’s 12 mpg example consumed ~ 2X more fuel than Leadbeater, coming in at a fuel consumption rate of 1.16 lb/hr/hp.

Just for clarity, my 840 Triton produced 72rwp. I assume fuel needs would be based on crankshaft horsepower, so I guess we would have to assume somewhere in the region of 80 crankshaft bhp?

That would put it at 425 ml/m.

- Status

- Not open for further replies.