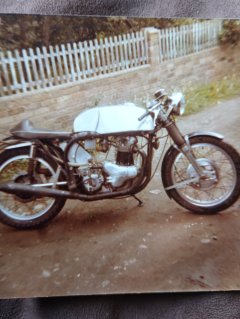

My hard mount 850 Commando motor in the Featherbed frame was balanced by an old English gentleman back in 1981 Ivan Tighe my cam builder here in Brisbane at the time put me on to this gentleman as soon as I told him what I was building he started to rattle off numbers and balance factors and what was needs for balancing, was too much for my young brain to absorb and I handed my crank, pistons, conrods, bearings, pushrods and all too him to do, he said around 72% balance factor.

Well whatever he did my hard mount Norton runs pretty smooth down low and mid-range but there are 2 rev ranges that the vibs in the handle bars that get a bit bad in the higher rev range but it smooths out over those two points in the rev range, other than that its quiet smooth around the suburbs, on the highway and where I use it the most up in the ranges so all the way up and over 100MPH its quiet good.

My stock Norton use to only rev to 6500 before losing it but after the balancing my crank, it revs very freely but have to be careful not to over rev it as it just keeps spinning up, but of course the crank is not the only thing that I have done too my motor but wasn't overdone.

My hoon days are no more but my motor works so well in my rev range, 2nd and 3rd gets a good workout throughout the rev range, but I no longer over rev my engine, but it gets up and over the ton very fast and surprises a lot of folks when out and about in the twisties.

I now run renthal 6.5 thick wall alloy handle bars and no longer get any vibs through the handle bars at those to rev ranges and in 44 years built this way I have only lost the top gearbox top mount nut and one nut off the left hand rear muffler nut, not bad for a hard mount motor that suppose to vibrate a lot and it was an everyday rider most of its life with me now its semi retired just like me.

Whether I been lucky or the old English gentleman knew what he was doing or I just have a freak Norton, but my 850 Commando/Featherbed has been the same way I built it in 1980/82 with only a few mods upgrades in the last 15 years, but the motor is very much the same when I first built it, it's a fun bike to ride, its light, plenty of torque and get up and go and handles like it's on rails, it's not as smooth as my 2016 1200 Thruxton but it's pretty good but it's not bad for a heavy 360 swing crank motor.

I love to build an 850 Commando motor with Jim's bits and pieces, but I don't have that much money in my kitty to play with, I built my motor when things were cheap to do and so far my motor has proved it worth for being reliable and not have things fall off since I brought it new, although its semi-retired now it's still my favorite bike to ride I have so much fun on it.

4 years as a Commando 44 years as Commando/Featherbed, would I do it again, sure would and would I change anything, no, as I have a 1960 Norton project bike build waiting to be restarted.

So yes, you can get them to run smooth with crank balancing if done right and in the right hands of the balancer.

Ashley