The bane of all projects right thereBusy weekend with kids activities, so little progress.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Build Thread" for my 1974 850

- Thread starter gatsby

- Start date

There is supposed to be an axle that works with the fittings in the bag that ride on the top rollers. Is that it at the top of the table?Progress…spokes in, and now I’m testing our different configurations in my new stand. Unfortunately the hub is just a little too small for the tapered “points” to hole the wheel in place. Can anyone chime in if they have faced this problem before?View attachment 101320View attachment 101321

gatsby

VIP MEMBER

Great advice! I will be bringing this up into l family room for sure!Not sure it can be too small. It's tapered to fit a variety of hubs. Mine fit fine which looks like a similar design

Tusk Motorcycle Wheel Balancing and Truing Stand | Parts & Accessories | Rocky Mountain ATV/MC

Shop for Tools, like Tusk Motorcycle Wheel Balancing and Truing Stand at Rocky Mountain ATV/MC. We have the best prices on dirt bike, atv and motorcycle parts, apparel and accessories and offer excellent customer service.www.rockymountainatvmc.com

BTW, i found it best to true the wheels on the coffee table watching sports and having a beer

Unfortunately the hub is just a little too small for the tapered “points” to hole the wheel in place.

Going by the picture below it looks like the balancing cones (in the bag on your bench) can be added to the truing cones.

BikeMaster Wheel Balancer 30cm X 54cm 800-256 for sale online | eBay

Find many great new & used options and get the best deals for BikeMaster Wheel Balancer 30cm X 54cm 800-256 at the best online prices at eBay! Free shipping for many products!

www.ebay.com

gatsby

VIP MEMBER

Yes - there is a axle that can go on the top rollers. This stand has both options. The axle is slightly smaller than the hub, but there are “O” rings on the axle to keep it in place.There is supposed to be an axle that works with the fittings in the bag that ride on the top rollers. Is that it at the top of the table?

bingo! Back in business! Thanks!There is supposed to be an axle that works with the fittings in the bag that ride on the top rollers. Is that it at the top of the table?

gatsby

VIP MEMBER

Yesir! Thanks again LAB!Going by the picture below it looks like the balancing cones (in the bag on your bench) can be added to the truing cones.

BikeMaster Wheel Balancer 30cm X 54cm 800-256 for sale online | eBay

Find many great new & used options and get the best deals for BikeMaster Wheel Balancer 30cm X 54cm 800-256 at the best online prices at eBay! Free shipping for many products!www.ebay.com

Great progress. Looking at the lift/stand photo and I see no securings to the frame . Big cables (zip ties ) would prevent a fall over.Progress…spokes in, and now I’m testing our different configurations in my new stand. Unfortunately the hub is just a little too small for the tapered “points” to hole the wheel in place. Can anyone chime in if they have faced this problem before?View attachment 101320View attachment 101321

gatsby

VIP MEMBER

Sound advice! I have completely forgotten about securing it. Thanks!Great progress. Looking at the lift/stand photo and I see no securings to the frame . Big cables (zip ties ) would prevent a fall over.

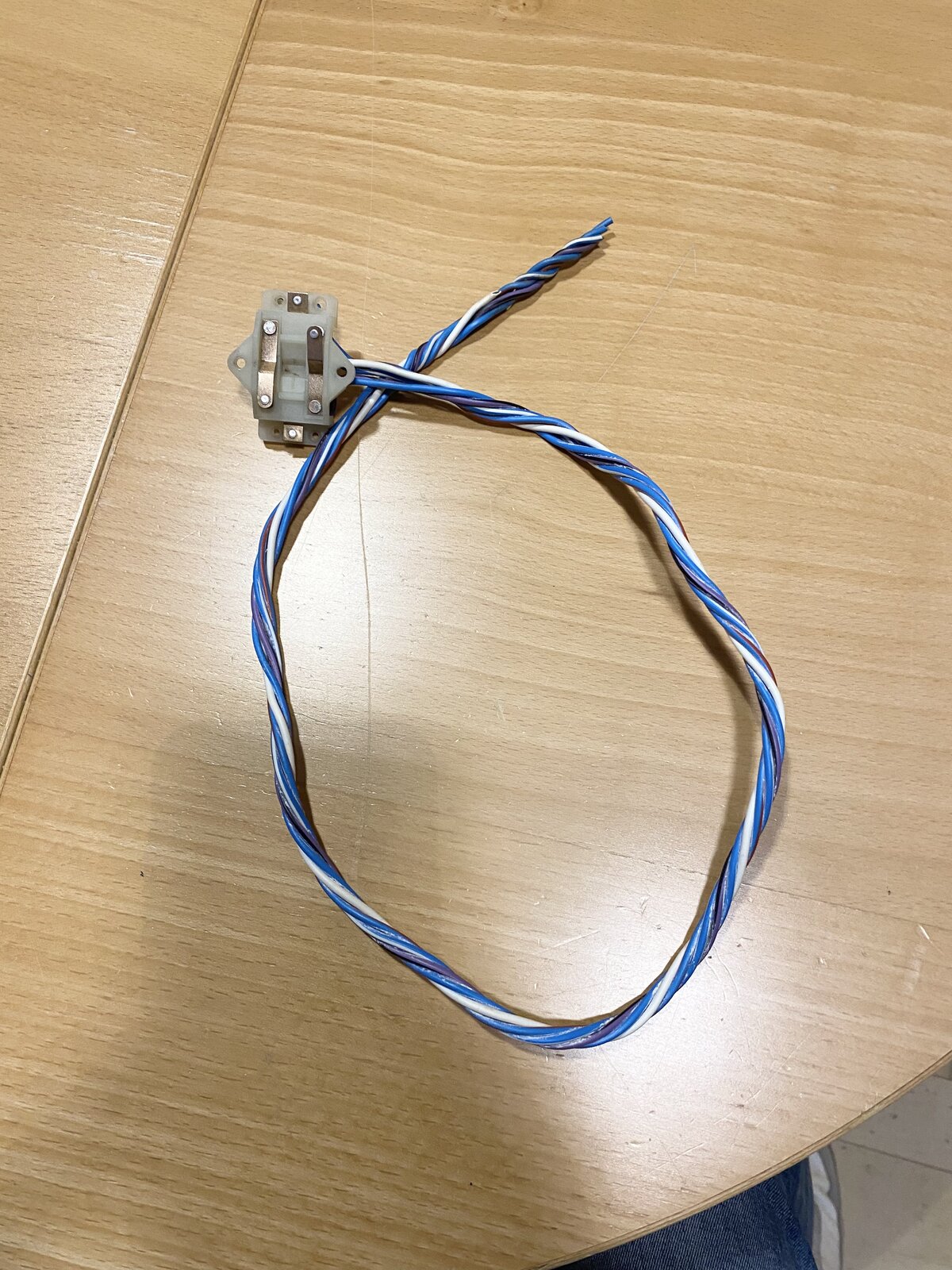

I’m putting my switch gear together, and the new thumb switch has a much shallower hole for the spring.

Do you mean two new levers for the switch clusters because the 3-position (direction indicators) and 2-position dip (Hi-Lo) levers in your picture are not interchangeable?

gatsby

VIP MEMBER

Good eye! Yes, I would need both. I have an old bag of tricks with switch gear parts, and I clearly do not have my glasses onDo you mean two new levers for the switch clusters because the 3-position (direction indicators) and 2-position dip (Hi-Lo) levers in your picture are not interchangeable?

gatsby

VIP MEMBER

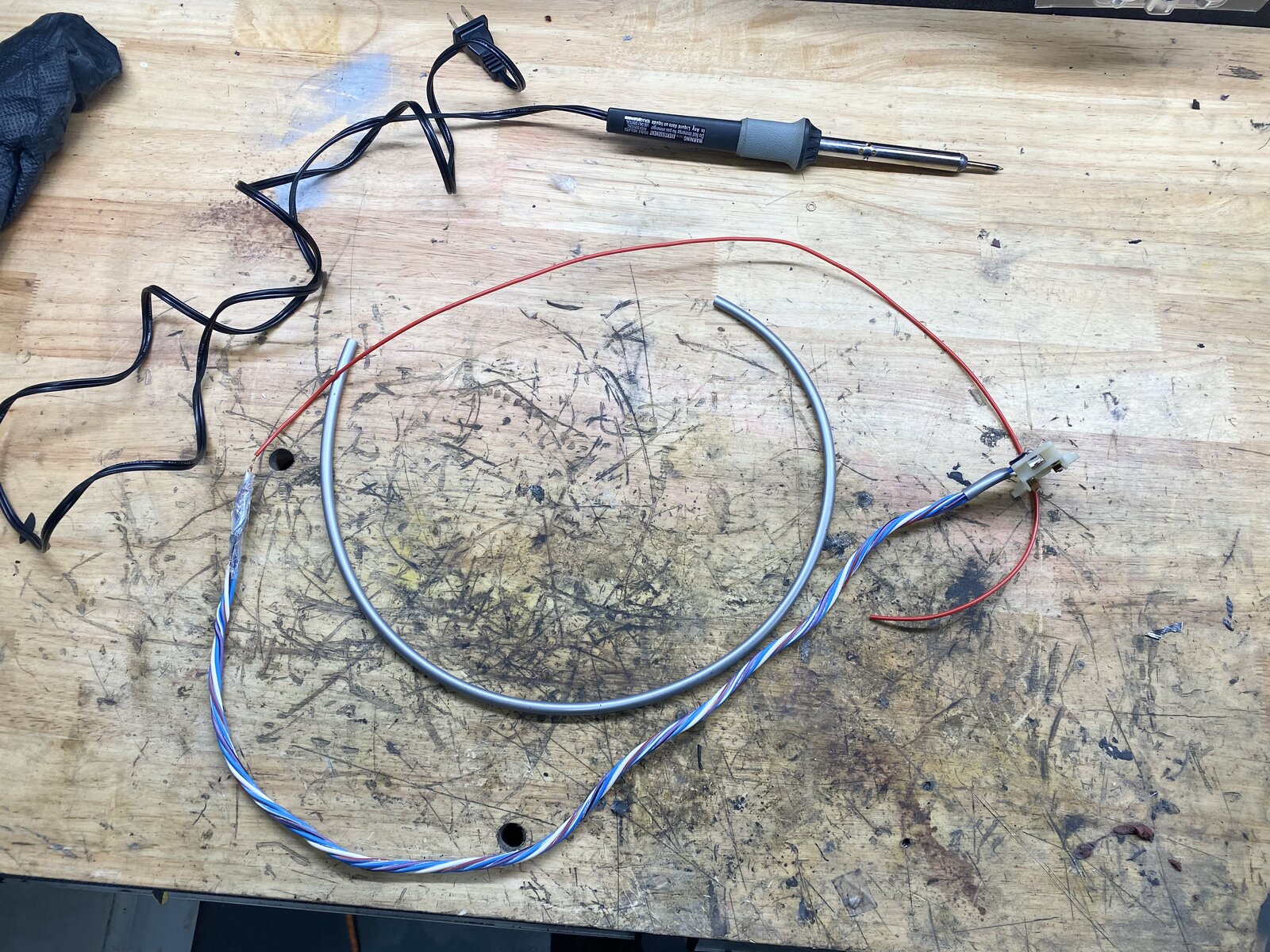

I did some experimenting with some 7mm ID PVC sleeving from Spark Moto. I first stripped off the original soiled and stained sleeving.

I then soldered a piece of wire to one of the switch gear wires. I tightly taped the remaining wires together (I ended up using proper non sticky black harness tape, this packing tape did not work). I fed the pull wire through the new PVC sleeve, and added some dabs of red rubber grease as I pulled. Once the pull wire poked out the sleeve, I secured it in my vice. I then slowly pulled and worked the new PVC sleeve over the wires with both hands, with the end secured in the vice.

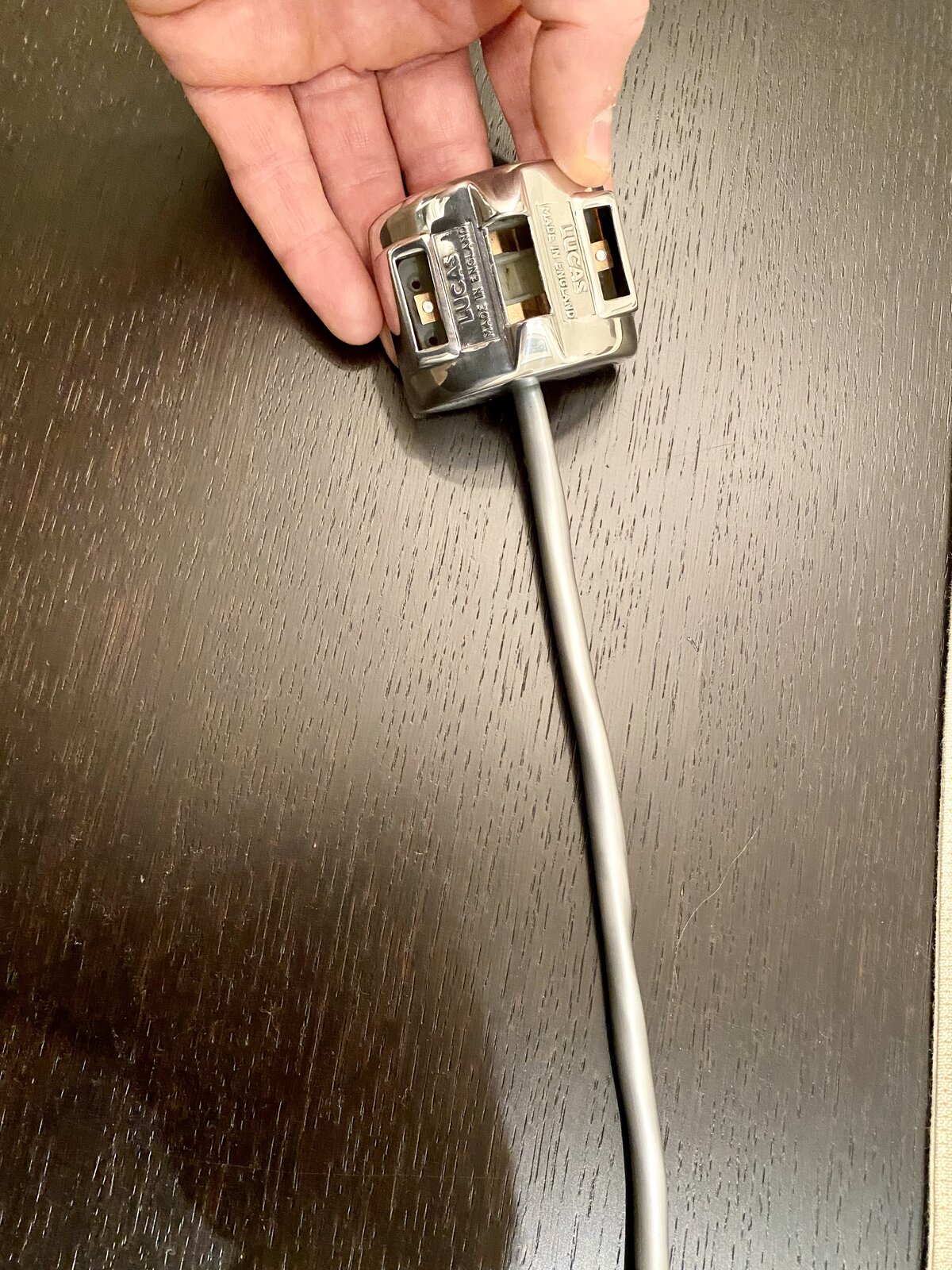

It turned out pretty good. Now I need to get some Lucas bullet connectors and a crimper (And finish the button/switch install of course)

I then soldered a piece of wire to one of the switch gear wires. I tightly taped the remaining wires together (I ended up using proper non sticky black harness tape, this packing tape did not work). I fed the pull wire through the new PVC sleeve, and added some dabs of red rubber grease as I pulled. Once the pull wire poked out the sleeve, I secured it in my vice. I then slowly pulled and worked the new PVC sleeve over the wires with both hands, with the end secured in the vice.

It turned out pretty good. Now I need to get some Lucas bullet connectors and a crimper (And finish the button/switch install of course)

gatsby

VIP MEMBER

Hi Everyone,

First update for awhile. I sure am looking forward to the holiday break to get more wrenching time. I have made some progress. I laced both of my wheels to the best of my abilities. Offsets are good. I appears that I had ordered tires and rim ribbons, but I forgot to order tubed. Doh! They are on order, and will hopefully arrive this week. I will then have a roller! My hand controls are built and mounted. Don Pender’s master cylinder fits the Lucas switchgear like a glove, and looks the business. I mated it to added a Venhill brake hose, and new RGM Bundy. Forks are assembled with oil. I had a pretty bad leak, and then I realized that I have forgotten to tighten the bolt on the bottom of the slider. Phew!

New seals are in place on the primary cover, and once I replace the pump seal I will mount it. I replaced the felt ring in the inner chain case cover (what a pain!), and now have it mounted. Belt drive install is next.

I test assembled the rear tail piece with new parts and hardware. The metal backing plate needed some shaping to sit right. I know its not Norton, but I thought it looked cool.

Progress!

Cheers,

Gatsby

Cheers,

Gatsby

First update for awhile. I sure am looking forward to the holiday break to get more wrenching time. I have made some progress. I laced both of my wheels to the best of my abilities. Offsets are good. I appears that I had ordered tires and rim ribbons, but I forgot to order tubed. Doh! They are on order, and will hopefully arrive this week. I will then have a roller! My hand controls are built and mounted. Don Pender’s master cylinder fits the Lucas switchgear like a glove, and looks the business. I mated it to added a Venhill brake hose, and new RGM Bundy. Forks are assembled with oil. I had a pretty bad leak, and then I realized that I have forgotten to tighten the bolt on the bottom of the slider. Phew!

New seals are in place on the primary cover, and once I replace the pump seal I will mount it. I replaced the felt ring in the inner chain case cover (what a pain!), and now have it mounted. Belt drive install is next.

I test assembled the rear tail piece with new parts and hardware. The metal backing plate needed some shaping to sit right. I know its not Norton, but I thought it looked cool.

Progress!

Cheers,

Gatsby

Cheers,

Gatsby

New seals are in place on the primary cover, and once I replace the pump seal I will mount it.

Timing cover? I can't be sure (as it's a low-res picture) but is the crank seal fitted correctly with the garter spring side away from the crankcase so facing the opposite direction to the camshaft seal? No circlip?

Also, the headlamp brackets are fitted on the wrong sides (and thus inverted). Fitted correctly the adjustment slots will be horizontal.

gatsby

VIP MEMBER

Hi LAB - here is an enlarged picture so it might be easier to see if I have the seals facing the right direction. They are both facing the same direction. Very high probability I have this wrong, as I did not take a picture of which way the seals were facing prior to removal. Surprisingly enough, I did remember the circlip after I took the picture!Timing cover? I can't be sure (as it's a low-res picture) but is the crank seal fitted correctly with the garter spring side away from the crankcase so facing the opposite direction to the camshaft seal? No circlip?

Also, the headlamp brackets are fitted on the wrong sides (and thus inverted). Fitted correctly the adjustment slots will be horizontal.

Ahhhh! those ears fell out so many times as I was trying to fit them by myself, and I did not pay attention to the direction they were installed. Thanks again LAB!

gatsby

VIP MEMBER

I 100% agree. I have too many hours put into these wheels to risk butchering them up mounting a tire!Looks good. From personal experience I recommend having a local motorcycle shop put on the tires

Yes, the crank seal (2) is facing the wrong direction because the oil flows from the timing cover to the crankshaft so the 'pressure' (lip with garter spring) side faces the timing cover gallery (factory manual, section C26).They are both facing the same direction. Very high probability I have this wrong,

gatsby

VIP MEMBER

Thanks for the save!! I would have completely missed this!Yes, the crank seal (2) is facing the wrong direction because the oil flows from the timing cover to the crankshaft so the 'pressure' (lip with garter spring) side faces the timing cover gallery (factory manual, section C26).