- Joined

- Sep 30, 2017

- Messages

- 325

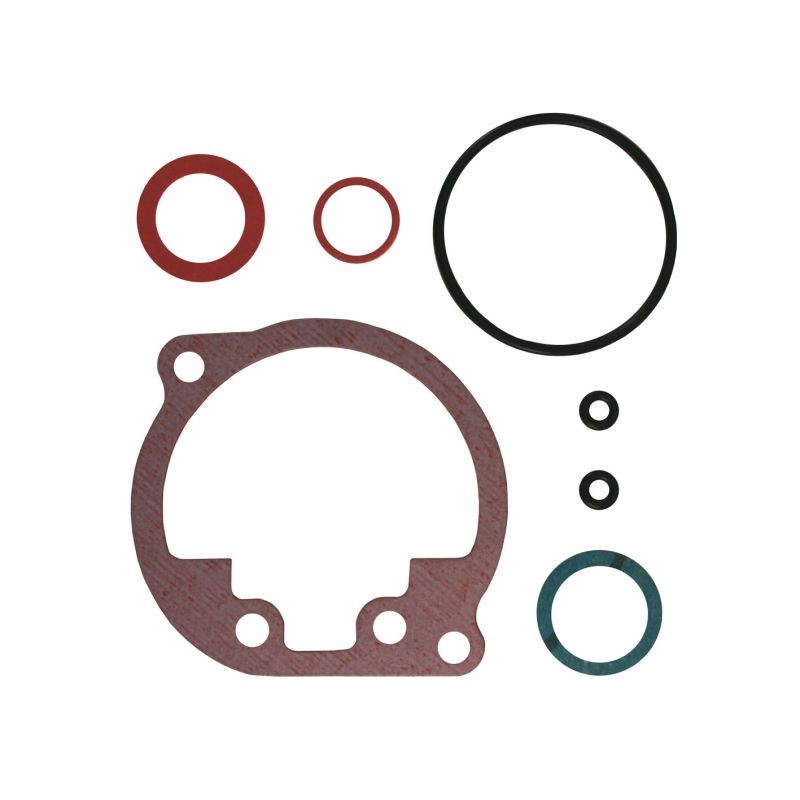

After having a constant dribble from carbs and non sealing taps I decided to order BAP taps and reseal the Mk 1 carbs. Once finished the (Premier) float bowls wouldn't seal at the drain and petrol was seeping up the thread from the banjo on the tap AND seeping from the joint where the dowty washer holds the tap in the tank.

So far I confronted the issue on the float bowls with using the old plastic screw plugs with the old thick green washers which had first been given a flat surface on some emery on a glass plate. To tighten them I use an old two shilling piece which seems to be made for the job.

Can these green gaskets be sourced still? In the Amal pack were only thin hard red ones supplied!

Now to the taps, my only theory to them is to use silikon tape to seal the threads but I wasn't enthralled by the look of the inverted conical joint where my banjo is bolted in to.

For now I have had enough inhaling of petrol, to the point I have a head full of it

and would dearly be glad to hear your input.

So far I confronted the issue on the float bowls with using the old plastic screw plugs with the old thick green washers which had first been given a flat surface on some emery on a glass plate. To tighten them I use an old two shilling piece which seems to be made for the job.

Can these green gaskets be sourced still? In the Amal pack were only thin hard red ones supplied!

Now to the taps, my only theory to them is to use silikon tape to seal the threads but I wasn't enthralled by the look of the inverted conical joint where my banjo is bolted in to.

For now I have had enough inhaling of petrol, to the point I have a head full of it

and would dearly be glad to hear your input.