Triton T120R pre-unit engine

- Thread starter Flatspot

- Start date

- Joined

- Feb 10, 2009

- Messages

- 3,043

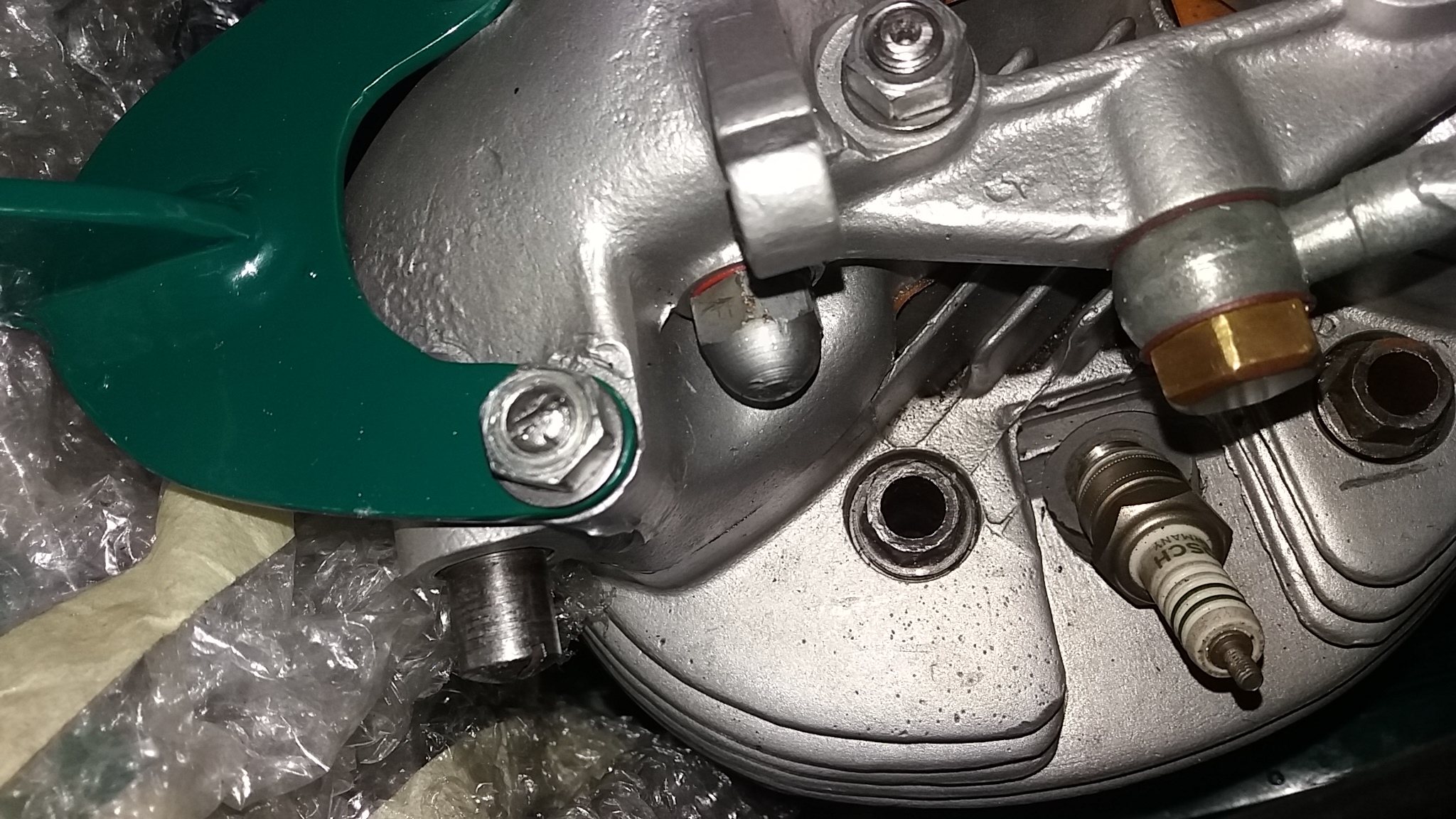

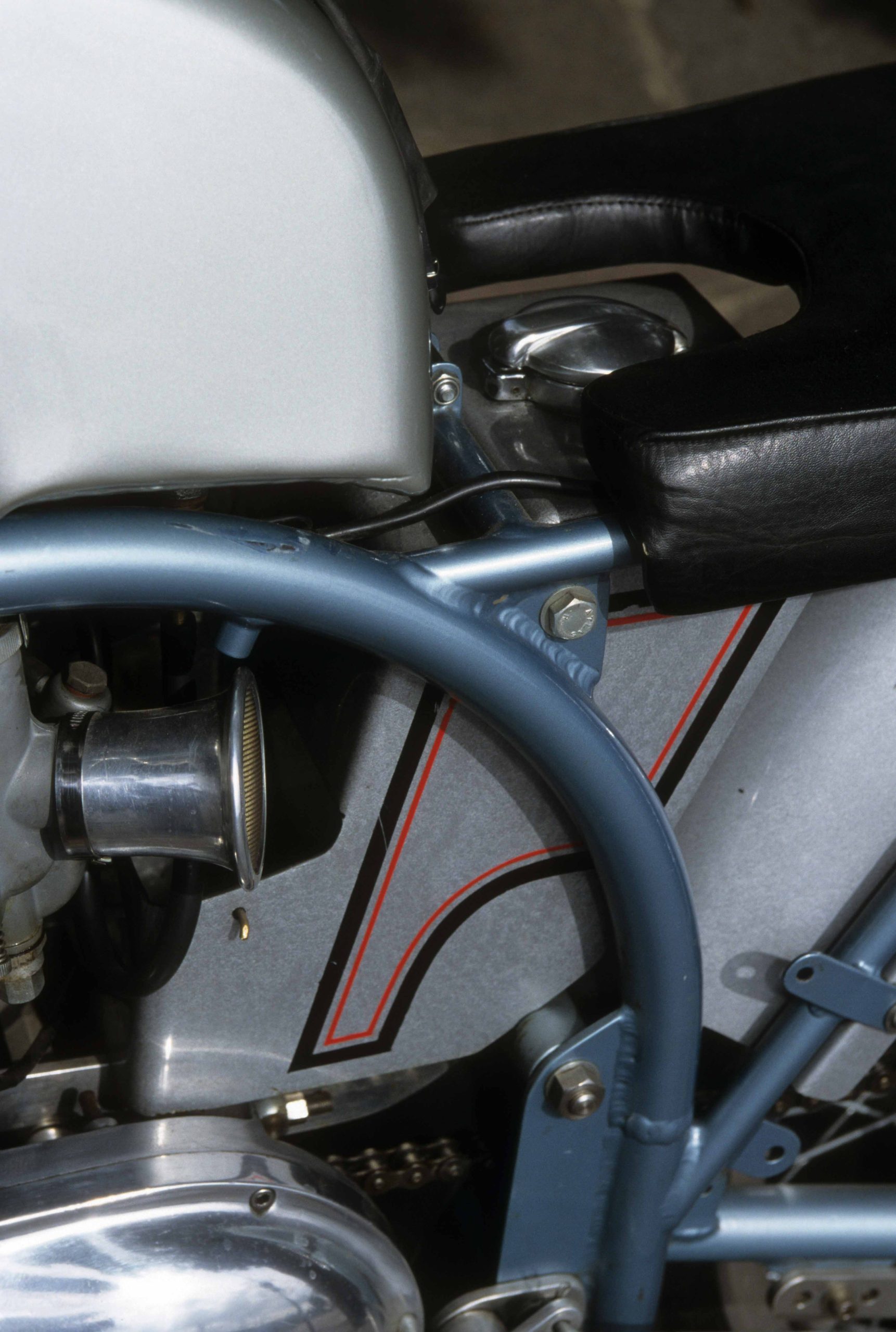

This arrangement of head steadies is junk, constructed by an idiot.

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,187

I have to agreeThis arrangement of head steadies is junk, constructed by an idiot.

A lot of people don't seem to realise the head steady on a feather bed frame forms part of it's structure

t ingermanson

VIP MEMBER

- Joined

- Oct 17, 2018

- Messages

- 622

Do a google image search for "Triton head steady", and it'll give you a good idea. Basically, you need a bridge between the tab on the back of the headstock, to the tab on the cross brace behind the head stock, to the rocker box studs. Make it out of 1/4"-ish plate.I’d appreciate your suggestion what I can do before I get around to reassembling it once more

There's a lot of cardboard and tape in your future.

- Joined

- Jul 25, 2010

- Messages

- 5,877

LIKE WE SAID ! : qrectrangle twixt FOUR BOLITS . and a fing upta THERE . Wot stopsit going back n forth , and falling off . The ole frontend , likewotitdid on the Vin Manx at puke a coee they said .

yer Clutch drum , amerem out , and get dressed .

Dress with semi fine FILE after having gently persuaded the BURRS back where the belong . shoulda bin hardened . HAVE A GOOD LOOK at the CENTER BEARING HARDENED SEAT , in the center .

thisiswhathereplaced it WITH . purloined from knockers . https://www.nortonownersclub.org/node/9530

NOW you wanna be sure its NOT vibe destructable Alloy or S Steel . Most would underbore head bolt holes and ream , CLOSE anyway .

Some have been know to bore Crankcase thru stud oles to 10 m.m. And fit 10 mm stainless studs . Bored 3/8 the 10 mm will tap in firm .

Another example of neccesity breeding sucess . THERE

You want SHANKED H.T. bolts to frame x 2 , at the FRONT there . And , if theres a cross brace aft to the bracing tube . or a lug , even ! - Go aft to THAT TOO .

Id CAREFULLY PAINT SRIP the frame , patiantly . dont let a Sand Blaster anywhere near it . Some leftem bare . SO THEY COULD SEE CRACKS . and it was lighter .

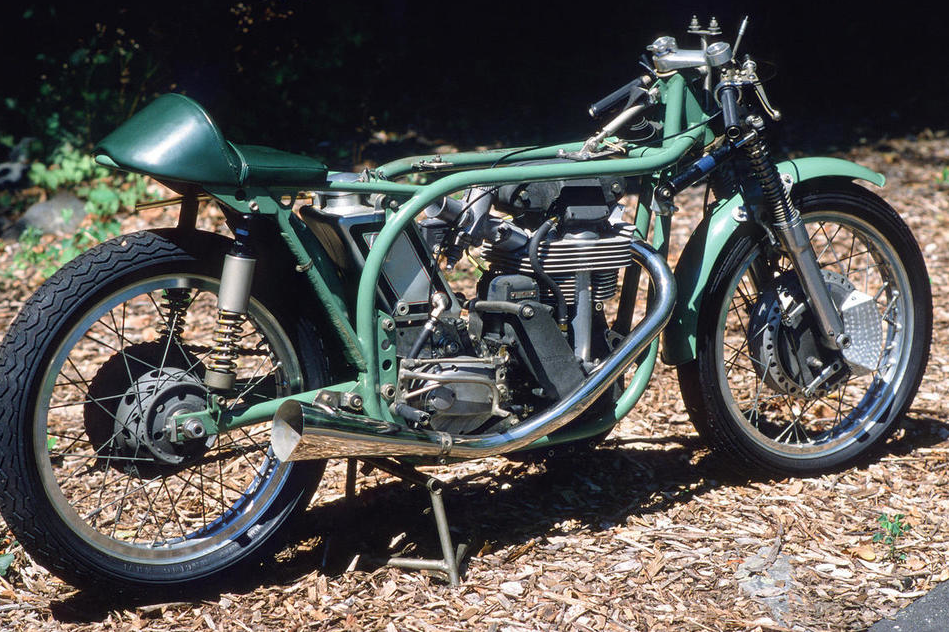

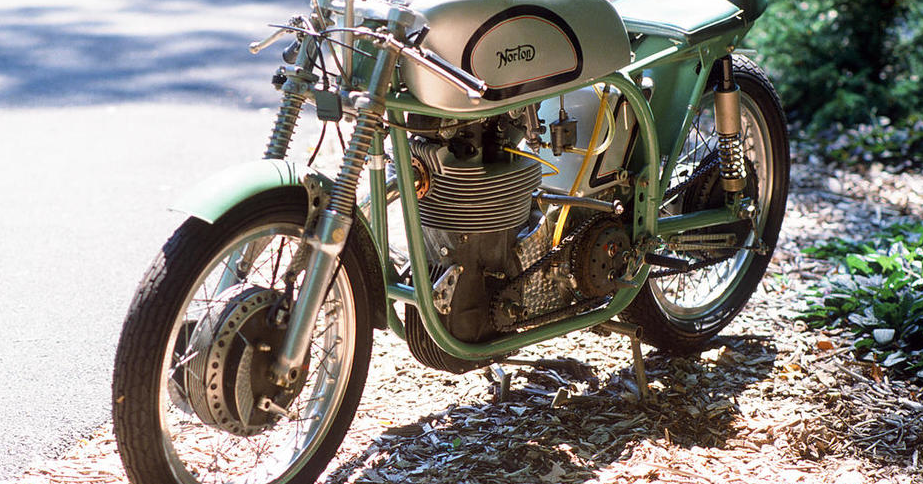

Pale Green & you can pretend your Fracis Beart .

Under The Hammer - ex Jimmie Guthrie, Francis Beart Manx Norton

It's not very often that such a fine racing motorbike comes up for auction. Actually, I guess that every year, there are plenty of signi...

Ducati Imola Blue ( metalic ) and you can dress as Dave Dedgens .

The original Dresda Triton is a loveable mongrel with race-winning pedigree | Hagerty UK

Roland Brown rides a 1965 Dresda Triton and finds that this Norton-Triumph mogrel is made of race-winning pedigree

They Obviously COPIED Maurie Lowes wideline TRITON T 100 R , Igot . donein 1960 maybe . couldabin earlier . anyone know . ?

Dresda Triton and Dresda Triumph

Dave Degens looks back at the pair of Dresda racers parked on the Montlhéry banking and says: “I never really liked riding here – I crashed in 1970 when I was blinded by the sun when I was right at the top. I hit the rail and came off. But Montjuïc Park, that was tight and twisty. The sort of...

T120 engines in Norton Featherbed frames

Apologies if this has been brought up before. Why is it that the cafe racer people like to substitute a T120 engine into a featherbed engine rather than use the more powerful 750 Atlas engine originally installed (or 650 dommie engine)? Is the evolved Turner engine better than Bert Hopwoods...

Was road tested , the dreda , after the race . Scotland & back .

Nuther GAME is RIDGID space twixt trans , for beter balance & location , if you do CUSTOM PLATES .

800 8 stud now in NZ , twin 32 Dellortos , dunlikeit . Otputs closer swing arm , cranks down'n'fwd. LOW . Steer Beter , and old the road . beta too .

Posn. Gearbox spocket optimumly to swing arm pivot , go from there . Norton or Trium box . triumphs tougher & 5 speeds cheaper too .

Last edited:

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,187

You are basically trying to triangulate the headstock to the motorI’d appreciate your suggestion what I can do before I get around to reassembling it once more

And stop the motor vibrating forward and backwards

You need minimum 6mm mild steel plate,not stainless or alloy

Not Powder coated but painted

The holes should be dead size to the bolts

The bolts should be shouldered high tensile with a fine pitch

I'd also pick up on the inlet and exhaust rocker box through bolts if you can rather than just the exhaust rocker box

All the above is just the way I'd go , others will have different opinions

- Joined

- Feb 10, 2009

- Messages

- 3,043

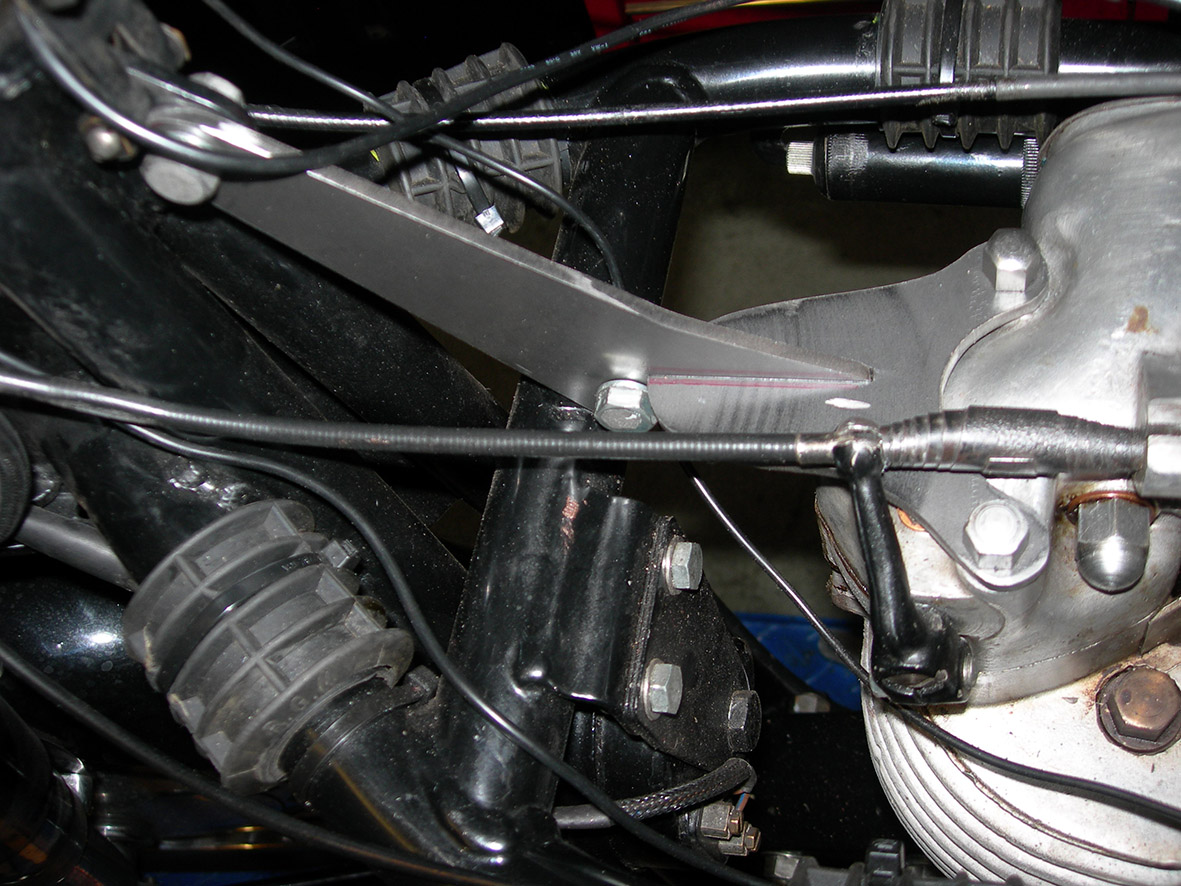

Here’s an example that is probably good enough.

Many people use a thick flat plate on the four cylinder head bolts and weld the vertical triangular part to it.

You can get away with only using the front two head bolts.

Many people use a thick flat plate on the four cylinder head bolts and weld the vertical triangular part to it.

You can get away with only using the front two head bolts.

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,187

Do you get rocker box gasket leaking problems if you only only use two studs?Here’s an example that is probably good enough.

Many people use a thick flat plate on the four cylinder head bolts and weld the vertical triangular part to it.

You can get away with only using the front two head bolts.

- Joined

- Feb 10, 2009

- Messages

- 3,043

Well I don’t, particularly, but I’m using a 650 iron head, which has different rocker boxes from the alloy head engines most people use. I actually can’t remember if there are gaskets between my rocker boxes and the head.Do you get rocker box gasket leaking problems if you only only use two studs?

I would never argue against using all four head bolts, but it involves a bit more drilling, which has to be accurate and buying an extra pair of bolts with the male threaded tops.

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,187

How many miles has it done in 60 plus years?Crumbs! There’s a lot to think about.

Bearing in mind the ones shown on my bike have been there for 60+ years with seemingly no issues what could it cause? I’ll need that top front mount to access the front fuel tank mount and strap.

Whatever you decide please make sure the headstock is properly supported how Norton designed it to be

Or you could end up with some very light steering

Flatspot

VIP MEMBER

- Joined

- Jan 30, 2020

- Messages

- 1,290

How many miles? No idea really. But the odometer at 23000 miles or so seems possible. How many miles will it do with me aboard? Probably rather less than a 10th of that in reality. Bike nights and shows only (or it may simply stay tucked away warmly in the garage)

It’s already likely to have slightly lighter steering as it has the longer wideline shocks fitted, and a centrestand with extended feet to cater for the increased height at the back.

It’s already likely to have slightly lighter steering as it has the longer wideline shocks fitted, and a centrestand with extended feet to cater for the increased height at the back.

t ingermanson

VIP MEMBER

- Joined

- Oct 17, 2018

- Messages

- 622

Mine are fine with no leaks using only the exhaust studs. That's how the Triumph motors are originally mounted.Do you get rocker box gasket leaking problems if you only only use two studs?

I used 1/4" 6061 alum plate, and bolted 1/4" 6061 angle plate like the above example that @Triton Thrasher posted. If you make the head steady too stiff, I think the motor's vibration may force leaks at the rocker box, and may crack a welded alloy version. Overthinking it might just make the situation worse, as the motor is going to vibrate with or without permission. I think any of the above are plenty strong for what's needed, and the original Norton part is hardly a fabrication masterpiece:

People are out there on all kinds of deathtraps, but this one does involve keeping the front end from separating, so probably worth going for. Missing the typical head steady that keeps the front end from wagging, you might check for cracks in the down tubes at the base of the "trouser gusset" below the head stock. It's a common mode of failure, which unsurprisingly might be exacerbated with a 16-year-old as original project engineer and test pilot.Bearing in mind the ones shown on my bike have been there for 60+ years with seemingly no issues what could it cause?

The top hole in the forward tab is used for the strap. If you're generous with the material, you can drill a new hole if need be in the head steady. I've found that the tanks on these bikes often want to slide forward, so a strap that goes down to the steady, around the front of the tank keeps it in place a bit better. No need if your tank doesn't slide around though.I’ll need that top front mount to access the front fuel tank mount and strap.

If you've got room in the tank tunnel, this type of head steady is also pretty handy for attaching all kinds of junk to, i.e., wiring harness, throttle cables, horn, etc, etc, etc. Keeps things snug that would otherwise rub.

Have a great vacation! Having a Triton project to come home to doesn't sound so bad either.

Last edited:

- Joined

- Feb 10, 2009

- Messages

- 3,043

Manx head steady.

Featherbed pushrod single head steady. Doesn’t look like the most rigid thing in the World.

Featherbed pushrod single head steady. Doesn’t look like the most rigid thing in the World.

- Joined

- Jul 25, 2010

- Messages

- 5,877

It'd depend if you have a twelve foot diameter Fontana Front Brake , megabuck race tyres , and intent to outbrake Velintino Rossi .

BAZ's brackets is the right principal .

Vibrations a bit of a missleading term , harmonious & sypathetic and things of that nature , so Absorbing & Transmitting , come into it .

But the " Head steady " is primarilly a " STEERING HEAD BRACE " . - 1/8 steel'd be min. 5/32 if drilled for lightening - polishing - impressing the neighbours etc .

with the widdle bitsat the bottom 1/8 , the Angles . There is one each side there . So the four bolts are utilised .

If your decadent , youd find a full matched set ?? of O E M period real steel HEAD BOLTS . the Lot . Better'n spending it on paint ! !

as theres expansion and osscilation in loads ! ( big word - thats it . ) say the front ' round holes ' 7 the aft two slotted 1/8 in ,

theyed go straight on .

Further to the Rdigid ( primary drivle ) If you are decadent and doing a BELT PRIMARY $$$$ , plywood plates / hardboard - between box & motor at something like the distance ,

The primary concern is if a chaincase , THAT dictates the rewardity , at the swing arm mount plate . And Fwd you would hope to have sump plate access .

concern is if a chaincase , THAT dictates the rewardity , at the swing arm mount plate . And Fwd you would hope to have sump plate access .

The front engine mount is primarilly vertical ' oscillation force ' location from the crank . Plus sideways then fore&aft . Whilst the REAR takes all the power transmision / thrust loads & torsional ( looking fwd at axle level , like ! ) As its NOT a UNIT , the two are less integrated . Therefore , they RUN SMOOTHER than a unit . if ya gettit right . No Paint in any connection - as its less directly secured with slimey paint in the joint .

ALSO , a CANTED engine , the vertical load distrobution is throw forward at the top & aft & down at the rear engine secureing / plates . rather than fat sitting on a hot griddle ! .

Be intresting someone fitting a infa red microdot to a commando craDLE FOR & AFT , OR AT THE ELASTICS , AND RECORDING oops the osscilation . around the Isle of Man .

BAZ's brackets is the right principal .

Vibrations a bit of a missleading term , harmonious & sypathetic and things of that nature , so Absorbing & Transmitting , come into it .

But the " Head steady " is primarilly a " STEERING HEAD BRACE " . - 1/8 steel'd be min. 5/32 if drilled for lightening - polishing - impressing the neighbours etc .

with the widdle bitsat the bottom 1/8 , the Angles . There is one each side there . So the four bolts are utilised .

If your decadent , youd find a full matched set ?? of O E M period real steel HEAD BOLTS . the Lot . Better'n spending it on paint ! !

as theres expansion and osscilation in loads ! ( big word - thats it . ) say the front ' round holes ' 7 the aft two slotted 1/8 in ,

theyed go straight on .

Further to the Rdigid ( primary drivle ) If you are decadent and doing a BELT PRIMARY $$$$ , plywood plates / hardboard - between box & motor at something like the distance ,

The primary

The front engine mount is primarilly vertical ' oscillation force ' location from the crank . Plus sideways then fore&aft . Whilst the REAR takes all the power transmision / thrust loads & torsional ( looking fwd at axle level , like ! ) As its NOT a UNIT , the two are less integrated . Therefore , they RUN SMOOTHER than a unit . if ya gettit right . No Paint in any connection - as its less directly secured with slimey paint in the joint .

ALSO , a CANTED engine , the vertical load distrobution is throw forward at the top & aft & down at the rear engine secureing / plates . rather than fat sitting on a hot griddle ! .

Be intresting someone fitting a infa red microdot to a commando craDLE FOR & AFT , OR AT THE ELASTICS , AND RECORDING oops the osscilation . around the Isle of Man .

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,943

You got the head off yet to establish whether or not it is a 750 ?

Flatspot

VIP MEMBER

- Joined

- Jan 30, 2020

- Messages

- 1,290

Not me. Years ago I would not have hesitated to rip it apart. However, although I have amassed a large number of tools over the years I don’t have things such as cam drive pullers - and I no longer have any expertise on an old Triumph engine. As such, I have taken the motor alone to a local highly recommended engineer who specialises in Triumphs.

My money on it is it’s a 650, and I’m happy with that, it was what I was expecting prior to actually doing the deal.

His brief is to strip it totally and advise me what requires doing to it. He has suggested that I replace the conrods with billet ones as we have no idea what has happened over the years, do we trust 60+ year old rods? - that will give me a spare set to go along with a spare set of TR6 cases, crank, cams, oil pump etc.etc. If I decide to sell off some ‘stuff’ to finance the build.

We won’t be looking to change cams for more power or anything else like that. It’s not needed, reliability is king.

I’ve asked him to ship the magneto off to a local specialist for refurbishing, condenser, points, remagnetise and such like. I know I could go for an electronic ignition conversion but it’s not how I want this to go back together.

What I will likely be doing is to strip and check the gearbox, and give it a good clean externally, new seals and bearings.

My money on it is it’s a 650, and I’m happy with that, it was what I was expecting prior to actually doing the deal.

His brief is to strip it totally and advise me what requires doing to it. He has suggested that I replace the conrods with billet ones as we have no idea what has happened over the years, do we trust 60+ year old rods? - that will give me a spare set to go along with a spare set of TR6 cases, crank, cams, oil pump etc.etc. If I decide to sell off some ‘stuff’ to finance the build.

We won’t be looking to change cams for more power or anything else like that. It’s not needed, reliability is king.

I’ve asked him to ship the magneto off to a local specialist for refurbishing, condenser, points, remagnetise and such like. I know I could go for an electronic ignition conversion but it’s not how I want this to go back together.

What I will likely be doing is to strip and check the gearbox, and give it a good clean externally, new seals and bearings.

t ingermanson

VIP MEMBER

- Joined

- Oct 17, 2018

- Messages

- 622

A freshly rebuilt magneto by a competent person with a good AAU is the epitome of reliability. While there are electronic options to replace the mag, they are not worth the headache of the battery maintanence and charging required.We won’t be looking to change cams for more power or anything else like that. It’s not needed, reliability is king.

I’ve asked him to ship the magneto off to a local specialist for refurbishing, condenser, points, remagnetise and such like. I know I could go for an electronic ignition conversion but it’s not how I want this to go back together.

While a pair of 3134 "q" cams with "r" lifters might be considered an upgrade from the stock cams on pre-unit motors, they became the stock cams on units and are the gold standard for Triumphs. They do not limit reliability, and offer easy starting and good torque.

It would also be worth having your cases checked for cracks. They are not indestructible by any means. If they are, it might be worth finding some "big bearing" cases. You can tell if they are, if there's a bulge under the bottom corner of the timing chest area. They are less likely to end up with a roached bearing, but the window of when the big bearing cases were made is fairly small.

These bikes are way more fun to ride than wax on about how much you hotrodded it into oblivion, so your approach is excellent!