You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replace Alternator Rotor??

- Thread starter WEM

- Start date

- Status

- Not open for further replies.

- Joined

- May 7, 2005

- Messages

- 7,174

Well ZF Services supplied the part according to the terms and conditions, so probably part of the Wassell group, as I know its rip off anyway I can't be bothered to research any further.

lucasclassic.com

lucasclassic.com

Lucas Classic | Terms of Use

TRADEMARKS

Please note that trademarks LUCAS, DIAGONAL (non-verbal trademark), LION AND FLAMBEAU (Lucas Classic non-verbal trademark) as well as the red and white trade dress shown on this web site, are owned by ZF Services UK Limited and may not be used without ZF Services UK Limited’s express written permission.- Joined

- Nov 20, 2004

- Messages

- 20,452

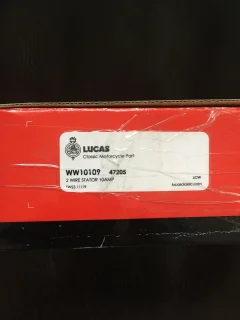

So from what I see , I was sold a Wassell knock off Lucas Stator ?

Technically, it is Lucas as Wassell are licensed to use the trademark.

Wassell Limited

In 2019, Wassell acquired the extended licence for Lucas Classic products, and Girling products worldwide, for Classic motorcycles. The Lucas Classic programme launched in 2019, and included the Lucas Classic Car, Lucas Classic Landrover, and Lucas Classic Motorcycle divisions."

Lucas Classic | Motorcycle

Lucas Classic | Motorcycle

Lucas Classic Motorcycle

111 Sadler Road

Lincoln

LN6 3RS"

Contact Us - Wassell Limited

"Contact Us

Wassell Ltd111 Sadler Road

Lincoln

LN6 3RS"

Craig

VIP MEMBER

- Joined

- Dec 20, 2005

- Messages

- 3,464

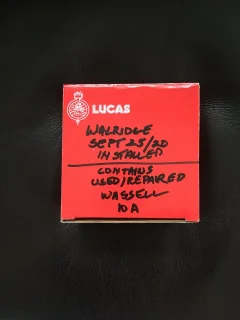

Still , I ordered the new stator from the man himself (Mike) Walridge after digging around looking for a better stator than what I had just repaired ..... he offered 2 choices with the Lucas a few dollars more .... no mention that in reality it was no better than the Wassell one it was replacing ... or is it ? ..... I did read what was linked and saw no real evidence of improvement ... I know how to swear like a worker in a ditch fixing a broken sewer pipe in -25C temps, but I won’t ....

- Joined

- Apr 15, 2009

- Messages

- 11,527

It's only a theory?Crank flex is only a hypothesis. Fortunately I didn’t suffer a catastrophic failure like you.

I was super careful in ensuring a min 10 thou gap on my 850, but when I stripped it (for other reasons) the rotor had clearly been fouling and the stator was looking very unhappy as a result.

The engine was revved hard, hence my crank flex theory. Can’t think of anything else?

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,657

It's only a theory?

Depends what you mean?

Of course it’s not a theory that the crank flexes, that’s pretty much fact.

But as to whether or not it flexed to the extent to be the casue of my issue, I do not know.

As @L.A.B. described very very thoroughly, Wassell are one of the companies that have purchased a license to use the Lucas name and logo (Wassell do not have exclusivity, there are other companies that have purchased the same license)

From my experience, and having had conversations with employees to confirm it, the Lucas alternator parts, whilst coming from the same suppliers as the Wassell parts go through several additional stages of final finishing and quality control.

A weighty component spinning at 6,000 rpm and having as little as 8 thou of clearance to a neighbouring part which is undoubtedly reduced when you snap shut the throttle from high revs needs all the help it can get.

For me, personally, I feel it is worth the additional money for the Lucas parts.

From my experience, and having had conversations with employees to confirm it, the Lucas alternator parts, whilst coming from the same suppliers as the Wassell parts go through several additional stages of final finishing and quality control.

A weighty component spinning at 6,000 rpm and having as little as 8 thou of clearance to a neighbouring part which is undoubtedly reduced when you snap shut the throttle from high revs needs all the help it can get.

For me, personally, I feel it is worth the additional money for the Lucas parts.

No, just because it is distributed by Wassell doesn’t mean it’s a ‘weak knock off’.

A ‘weak knock off’ would suggest poor quality and illegally labelled/branded.

In my experience they are good quality, and the licensing situation is clearly declared on Wassell’s website as @L.A.B. has pointed out.

A ‘weak knock off’ would suggest poor quality and illegally labelled/branded.

In my experience they are good quality, and the licensing situation is clearly declared on Wassell’s website as @L.A.B. has pointed out.

Lineslinger

VIP MEMBER

- Joined

- Feb 26, 2017

- Messages

- 1,790

Don’t recall color of boxes , I do remember the toasted Wassel stator I was replacing was branded as Wassel , the new item from Walridge motors was branded as Lucas as was the rotor .... I had mined the Wassell stator and repaired broken wires , turned out to be a wasted afternoon in bike shed as I had no faith in my repair , used it most of this season with no troubles but found myself staying close to home , so ordered up the new kit and now at least in my mind I’m free to roam on the old bike .... no doubt I have old stator in new box , will take a look in the morning ...

- Joined

- Apr 15, 2009

- Messages

- 11,527

What was the outcome of the bad stator? Did it get replaced by the vendor? Did you go with a different brand?I had an electrical issue earlier this year with my 1974 Commando 850 which, with considerable help from forum members, was ultimately diagnosed as a bad stator. Sure enough, when I pulled the primary cover off to investigate, the stator epoxy? coating was cracked and looked like it was partially melted at one location. A new stator is definitely a must. However, my question now relates to the existing rotor. The rotor came off easily and looks good physically. No obvious signs of damage. The rotor will hang unsupported from a wrench handle so the magnets appear to be holding their magnetism as well. I'm wondering if it's false economy to re-use a 46 year rotor as opposed to spending $140.00 CAD for a new rotor, or if buying a new rotor is an unnecessary expense given that the old one seems fine?

I just got a Lucas stator and I’m a little nervous. The Sparx stuff has been so bulletproof.

- Joined

- Nov 11, 2013

- Messages

- 5,396

Can't answer you're specific question, but I have had a new Lucas stator/rotor (not Wassell) for ~4 years. The only issue I have had was the protective wiring sheath got very brittle snd cracked in ATF. I had to get some oil resistant heat shrink over it in thru the primary and repot the end into the stator with black silicone RTV.What was the outcome of the bad stator? Did it get replaced by the vendor? Did you go with a different brand?

I just got a Lucas stator and I’m a little nervous. The Sparx stuff has been so bulletproof.

- Joined

- Dec 8, 2017

- Messages

- 154

What was the outcome of the bad stator? Did it get replaced by the vendor? Did you go with a different brand?

I just got a Lucas stator and I’m a little nervous. The Sparx stuff has been so bulletproof.

I replaced the bad stator, which was the original 46 year old stator, with a new Lucas RM24 three phase stator over the winter season. I haven’t had the bike started yet for this season. Still not conducive to comfortable riding here yet weatherwise. The installation went pretty well apart from a little fiddling to get the required spacing between the new rotor and the new stator. However, I’m now second guessing the install a little. The new rotor nut has been torqued to 80 ft-lbs as per the original Workshop Manual but I didn’t think to loctite the nut. No mention of Loctite in the manual, which is probably not surprising given that the manual is also 46 years old. My quandary now is that I recently came across a source which recommends loctiting the rotor nut and I’m wondering if it’s worth the effort to take everything apart again to apply loctite given that the rotor nut has been torqued to spec. The primary is buttoned up with a new sealing band and no leaks. The foot peg and brake assembly has been reinstalled and those nuts have loctite.

robs ss

VIP MEMBER

- Joined

- Aug 16, 2016

- Messages

- 3,578

I have found a useful improvement over the method the manual offers is to install 3 pieces if 0.010" shim stock, at 120 degrees apart, between the rotor and the stator whilst tightening the stator nuts. Afterward, remove the shims, no checking required - it's already equalised.The installation went pretty well apart from a little fiddling to get the required spacing between the new rotor and the new stator. However, I’m now second guessing the install a little.

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,657

If you tightened it to 80 ft-lbs and use the correct spring washer I see no reason its gonna want to come off.I replaced the bad stator, which was the original 46 year old stator, with a new Lucas RM24 three phase stator over the winter season. I haven’t had the bike started yet for this season. Still not conducive to comfortable riding here yet weatherwise. The installation went pretty well apart from a little fiddling to get the required spacing between the new rotor and the new stator. However, I’m now second guessing the install a little. The new rotor nut has been torqued to 80 ft-lbs as per the original Workshop Manual but I didn’t think to loctite the nut. No mention of Loctite in the manual, which is probably not surprising given that the manual is also 46 years old. My quandary now is that I recently came across a source which recommends loctiting the rotor nut and I’m wondering if it’s worth the effort to take everything apart again to apply loctite given that the rotor nut has been torqued to spec. The primary is buttoned up with a new sealing band and no leaks. The foot peg and brake assembly has been reinstalled and those nuts have loctite.

Yes... next time you’re in there add some loctite for good measure.

No... stripping it down just to do that is not necessary IMHO.

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 7,937

After using this method I would still turn the engine and check the clearance with the crank in different positionsI have found a useful improvement over the method the manual offers is to install 3 pieces if 0.010" shim stock, at 120 degrees apart, between the rotor and the stator whilst tightening the stator nuts. Afterward, remove the shims, no checking required - it's already equalised.

- Joined

- Dec 8, 2017

- Messages

- 154

Thanks to all for the responses. I think I’ll leave it until the next time I have the primary cover off.If you tightened it to 80 ft-lbs and use the correct spring washer I see no reason its gonna want to come off.

Yes... next time you’re in there add some loctite for good measure.

No... stripping it down just to do that is not necessary IMHO.

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 21,657

S’wot I’d do.Thanks to all for the responses. I think I’ll leave it until the next time I have the primary cover off.

Even then, wicking loctite could be used so as not to have to disassemble ...

- Joined

- Aug 14, 2009

- Messages

- 144

Hello everybody,

i rebuild my engine this winter.

(BTW: many thanks Jim S.! I am so happy with yours parts! My Norton runs wonderfully and is a pleasure to ride!)

I fitted also a new Lucas RM24 stator – because the wires of my old Sparx were looking unhealthy where they come out of the bakelite….

When i put the new on I controlled several times in several crankshaft positions (turning engine and controlled again) the stator – rotor – gap : of course!

Gap was less then with the Sparx – but in the specs given by Lucas.

First start……engine runs several minutes without driving: no problems

First testride and inspection of engine and primary – no problems

Second testride this friday: Stator cracked and damaged.

Same happened to a friend of mine with his Commando and a new Lucas stator 2 years ago…

Next: I made a total rebuild of a 1962 T100ss Tiger the last months.

Same procedure as I always do with recontioned or new engines:

First start: engine running without driving – no problems

First testride: no problem

Second testride: stator cracked and damaged

Measured ID of both new Lucas RM24: hardly 75mm (some 74.8mm)

Me thinking this is too less!!!

Sparx got 76mm ID and non problems the last 10 years……..with many many kilometers of hard riding in hot and cold climates

What do you think what should be the difference between rotor OD to stator ID?

What would be the maximum difference so that the power output is not influenced in a bad way….?

Difference between Sparx stator to rotor is 2mm and works fine………I think this is the minimum gap that works....

i rebuild my engine this winter.

(BTW: many thanks Jim S.! I am so happy with yours parts! My Norton runs wonderfully and is a pleasure to ride!)

I fitted also a new Lucas RM24 stator – because the wires of my old Sparx were looking unhealthy where they come out of the bakelite….

When i put the new on I controlled several times in several crankshaft positions (turning engine and controlled again) the stator – rotor – gap : of course!

Gap was less then with the Sparx – but in the specs given by Lucas.

First start……engine runs several minutes without driving: no problems

First testride and inspection of engine and primary – no problems

Second testride this friday: Stator cracked and damaged.

Same happened to a friend of mine with his Commando and a new Lucas stator 2 years ago…

Next: I made a total rebuild of a 1962 T100ss Tiger the last months.

Same procedure as I always do with recontioned or new engines:

First start: engine running without driving – no problems

First testride: no problem

Second testride: stator cracked and damaged

Measured ID of both new Lucas RM24: hardly 75mm (some 74.8mm)

Me thinking this is too less!!!

Sparx got 76mm ID and non problems the last 10 years……..with many many kilometers of hard riding in hot and cold climates

What do you think what should be the difference between rotor OD to stator ID?

What would be the maximum difference so that the power output is not influenced in a bad way….?

Difference between Sparx stator to rotor is 2mm and works fine………I think this is the minimum gap that works....

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 469

- Replies

- 13

- Views

- 869