ES234

VIP MEMBER

- Joined

- Apr 5, 2014

- Messages

- 72

Hi Ralph,I have an engine and I have sourced an aluminium head for it with a view to tuning it but that is as far as I got, mainly due to racing a twin.

I would be interested in what you have done to make it rev to 8500 and not lunch the motor. What crank, rod and piston do you use and what work has been done to the head, pretty much all your trade secrets so I do understand if you decide not to divulge this info.

The running gear would closely follow what I have on my Seeley.

Ralph.

A brief synopsis of a possibly wasted life:

"ES1" was an "iron" engine with improved porting, a 32mm Amal Concentric carb, 0.400" valve lift cams with appropriate timing, 12.5:1 on methanol, a modified standard crank 79 x 100mm. Single plug cylinder head set @ 32 degrees BTDC. Lightened rocker gear, standard cam followers. Revs were limited to 6,200 rpm pulling cleanly from 3,300 rpm. and probably made about 46/47 rear wheel BHP. Semi close gearbox ratios chosen to suit the power characteristics of the bike. Factory cases. "Tuned" length exhaust. The motor was punchy but ultimately fragile. (A photo of a young me on "ES1" circa 1981/2 Amaroo Park Sydney/NSW).

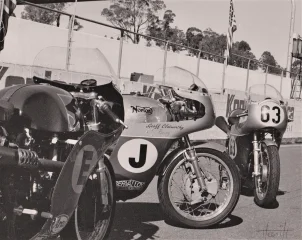

"ES2" was may first all allloy motor saving considerable weight, the distribution of which resulted in a significant improvement in the handling of the bike. Steel press up crank 80 x 100mm with a custom steel Carillo 7" rod and an INA big end. Modified standard main bearing arrangement. Arias custom piston 12.8:1. 48mm inlet valve, std diameter exhaust valve both in 21 4N 5/16" diameter stems. Gold Star or equivalent valve springs (R&D) set to provide 100lb seated/ 180-220lb "on the nose". 0.425" peak lift at the valve with appropriate valve timing. 1 3/8" Amal G.P. carburetor jetted for methanol. 15 degree down drought inlet with improved flow. exhaust port reduced in diameter by closing in the floor. Twin plug magneto set at 31 degrees BTDC (could have used a little less). 4 speed close ratio box. Factory cases. "Tuned" length exhaust. 5 speed Quaiffe box. 49 rear wheel BHP, but now a more robust motor. (A photo of "ES2" at Oran Park/Sydney circa 1988-90).

'ES3" my second alloy motor. Further improved head with similar valve sizes to "2". Similar steel crank but now with a more robust needle roller main bearing arrangement in slightly modified factory cases to accept such. 1 1/2" Amal GP and then later a 38mm Gardner both tuned for methanol. Twin plug magneto . Currently 14:1 with custom C.P. piston. 80 x 100mm crank , INA big end, 7 " custom Carillo rod all basically as per "2". 0.425" max inlet/exhaust valve lift. "Tuned" length exhaust. Now using 22 degrees of ignition/ twin plug magneto. 6,800 peak use rpm preferred ,but will rev cleanly to 7,000 rpm if required. 51 rear wheel rpm with a "fresh" engine. Bike weight with full fairing, oil but w/o fuel 107kg (236lb). A good package that could be built by anybody with the skill, time and patience. A frequent podium finisher, capable of winning with a good rider on board. I have had a few. (Photo of the current piston design x 2) + Photo of ES3 (rider Mike Soderland) 1st, ES3 (rider John Cronshaw) 2nd, and Glen English (Beale G50 3rd - Eastern Creek INCA meeting a long time ago .

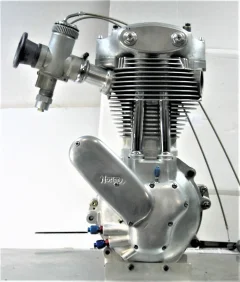

"ES4" uses a "full house" 90mm bore engine. One piece crank (2.1" crank journal/slipper bearings). Custom titanium rod 1.86 ratio). Modified high speed/high flow pump providing 70 p.s.i hot (regulated). 60 degree included valve angle, 1.62/1.58 custom rockers providing 0.625"/0.585" valve lift. Titanium valves. Roller cam followers. Appropriate valve spring choice to accommodate with 140lb seated/365 lb at full lift which translates to 590lb back at the follower. Special slotted cam gear wheel arrangement to accurately set the cam timing. Eccentric rocker spindles to set the tappet clearance ("lash" I believe is the US term). Substantial main bearings (caged needle rollers), running on a 1 3/4" D.S journal and 1 1/2" T.S. Improved rocker box holding down arrangement. Modified standard crankcases. 13.6: comp custom piston. A lot of cylinder head work with a compact shallow chamber (have a look at the Ilmor Mercedes chamber). 60+ rear wheel BHP. Pulls cleanly from 4,000 rpm. Custom hydro-formed tuned length exhaust. 5 speed TTI 'box.

I doubt that anybody will ever be as foolish or committed to build a better push rod Norton single cylinder engine, and I have been privileged to have seen inside a few here, and around the world. Peter Lodge (NZ) runs a similar set up with his own independent proven ideas and development program. (Photo of the engine on it's first complete assembly).

It is of course all in the detail which would take too much to go into here. After 40+ years of development, I don't think that I can extract much more performance from the humble ES2 engine, and I am probably now a little exhausted.

Sorry but these photos are out of sequence, but I am sure that you can sort it out.

Cheers - Geoff

Attachments

Last edited: