As previously noted, we've got another place for talking planes, aerobatics, inverted flight etc, so please keep those thoughts in that other repository. Thank you.

Unfortunately, much of the preamble and context relating to this subject has been deleted and/or locked, thus it is difficult for contributors henceforth to accurately quote the previous material, or worse, to review it and comment on it (since it no longer exists and is now locked out).

That said, at this juncture it seems virtually impossible to say something new or different than what has already been said, and which in turn has either been refuted or whole heartedly endorsed depending on view point. Interesting how we all see the same information, yet think totally different thoughts. In light of the above comments please allow me to voice my opinion on one aspect of "Rowley and the Magic Tube". And speaking of Mr Rowley, perhaps it would be fitting to thank Mr Rowley for the excellent job he did of improving the drivability of certain CDOs provided in a given configuration.

Background

I had been eagerly following and enjoying "Rowley and the Magic Tube" here on the forum, until the point of catastrophic deletions. A recent carb rebuild got me thinking about the relationships between the carb circuits, needles, needle jets, throttle openings, velocities, pressure depressions, magic tubes, rpm regimes, and roll-on results. I was curious about what range of rpm Rowley was probing with his 40-60 mph roll-on, and the many Forum voices suggesting that nobody really operates a motorcycle like that or that it is an unrealistic test. The combination of the deletions and my poor memory leave me unclear as to what the test actually was. I seem to recall clearly that the test occurred between 40-60 mph, but regarding throttle actuation rate, I believe the words "sudden acceleration" as well as "snapping the throttle open" were both used, though it remains unknown (at least to me) exactly what throttle opening rate each phrase refers to or what rate Mr Rowley employed. Do they refer to opening the throttle in 0.1 sec, 1 sec or 2 seconds, each of which IMHO would lead to dramatically different results.

Thus the following thoughts relate to the test method and conclude with some modern day roll-on results with a stock unmuted 850.

Rowley's RPM Regime

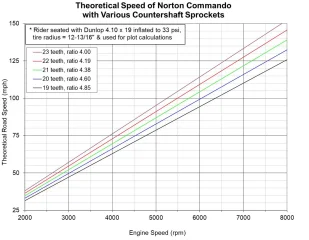

To start let's try to get a better handle on the possible engine rpm that Rowley explored. Using my '74 850 fit with 20 tooth countershaft sprocket as a model (was this the std sprocket they were shipped with?, don’t know, but somebody here does) the following plot was created.

The plot suggests that for my specific bike, Rowley would have been exploring an rpm regime from ~ 2400 to 3600 rpm. Within experimental error, my tach and speedo agree favorably with the plot data.

Roll-on Rates and 40-60 MPH Time Intervals

At times I operate a motorcycle in a fashion similar to Rowley, i.e., rolling on lots of throttle at 40 mph, so if this is what he was doing it is not an unrealistic test to me. I don't instantly roll to full throttle, but yet get there in a second or 2. Do I snap the throttle open in 0.1 sec? NO! Have I turned the throttle from a 40 mph cruising speed to full throttle in 1-2 sec? All the time. I figure the least you can do for the poor bike is to afford it the common courtesy of rolling (not snapping) the throttle on, thereby affording the poor beast some vague semblance of the rate a CV carb slide might actuate at, which in turn serves to maintain air velocity and allow a smoother transition between circuits. CV carbs were made for people that like throttle snapping, i.e., those that don't understand optimum throttle modulation, where the carb does it all for you regardless of the butterfly position. That must be why they came on my 78 BMW R100S!

My '74 850 is likely no different than anybody else's, and when cruising at 2000 rpm in high gear, will pull up cleanly without a stutter or blubber if the throttle is opened at a reasonable rate, i.e., perhaps 2 seconds to full throttle.

Several people made the point previously that dyno runs with A/F ratio monitoring is the best/only way to understand Rowley's solution, and I wouldn't argue that point. I was nevertheless curious to see how my freshly tuned bone stock '74 850 would operate in a test similar to Rowley's.

Some might ask "what does this have to do with Rowley's muted experiment?" Nothing. "Then why would you waste your time thinking and experimenting with such a subject?" Because I wanted to know the general time interval required for a decent running 850 to get from 40-60 mph, thereby gaining a better feel for what Rowley was doing and ultimately achieved.

The subject stock bike has points ignition, auto advance, cross-over exhaust header, and peashooters that are straight through, i.e., no intentional restriction other than 3 longitudinal rows of shallow baffle indents that face forward, with 1-3/8" ID and exit. The carbs are stock Amal Mk1 932s with Rowley's magic tube, 4 ring needle with clip in top groove, 106 needle jets and 260 main jets.

A stop watch was used to explore throttle opening rate and it was observed that a throttle can be snapped open in ~ 0.1 sec, opened comfortably in slightly over a second (1-1.2 sec), or opened very leisurely in 2 sec. Roll-ons from 40-60 mph were timed using different throttle opening rates, where at least a dozen runs were undertaken at each rate. Is the experiment perfect and can the rate of throttle opening be repeated exactly on each run? Of course not. Can a fairly decent job of getting the throttle open at the desired rates of 0.1, 1 sec or 2 sec time interval be achieved? Absolutely!

The slowest roll-on resulted in the shortest acceleration times which fell between 3.8 and 5.0 seconds. In this slow roll-on test, the bike was often over 50 mph before the throttle was 1/2 open. Likewise, the intermediate throttle opening rate gave acceleration times of ~ 4.0 to 5.2 sec. On some of these intermediate opening rate runs, there was a single hiccup occurring earlier in the run that momentarily slowed the acceleration process, thus resulting in the slightly longer times. The throttle snap sequence provided the slowest runs that tended to fall between 5.5 and 7.0 seconds. During all the throttle snap runs the engine behaved exactly like one would predict, it instantly lost fire as if both plug wires were pulled, yet very quickly gathered itself and yanked like hell up to 60 mph. This lag in circuit transitions accounts for the longer acceleration times associated with throttle snaps.

All in all I was surprised at how quickly our stock bikes cover the 40-60 mph interval, and especially how quickly they hit 50 mph - almost as soon as the throttle was eased on. For whatever reason, my intuition was that Rowley's test required a considerably longer time interval, but if his test bike gearing was like mine, suspect it was likely on the order of 5 seconds give or take.

Lastly, if Mr Rowley was snapping the throttle open, I'd be stunned if the bike actually pulled through with zero hesitation, but only he could inform on that front. It would be interesting to know more about "the test" and if his results relate or agree with the results reported here. Perhaps if Mr Rowley is reading this he might provide his thoughts to us by posting here or by sending them to me or a moderator for posting.

Would also be interested to hear from others that might be so inclined as to time a few roll-ons with different rates of throttle application to see if the time intervals or engine responses are similar or vastly different.

Unfortunately, much of the preamble and context relating to this subject has been deleted and/or locked, thus it is difficult for contributors henceforth to accurately quote the previous material, or worse, to review it and comment on it (since it no longer exists and is now locked out).

That said, at this juncture it seems virtually impossible to say something new or different than what has already been said, and which in turn has either been refuted or whole heartedly endorsed depending on view point. Interesting how we all see the same information, yet think totally different thoughts. In light of the above comments please allow me to voice my opinion on one aspect of "Rowley and the Magic Tube". And speaking of Mr Rowley, perhaps it would be fitting to thank Mr Rowley for the excellent job he did of improving the drivability of certain CDOs provided in a given configuration.

Background

I had been eagerly following and enjoying "Rowley and the Magic Tube" here on the forum, until the point of catastrophic deletions. A recent carb rebuild got me thinking about the relationships between the carb circuits, needles, needle jets, throttle openings, velocities, pressure depressions, magic tubes, rpm regimes, and roll-on results. I was curious about what range of rpm Rowley was probing with his 40-60 mph roll-on, and the many Forum voices suggesting that nobody really operates a motorcycle like that or that it is an unrealistic test. The combination of the deletions and my poor memory leave me unclear as to what the test actually was. I seem to recall clearly that the test occurred between 40-60 mph, but regarding throttle actuation rate, I believe the words "sudden acceleration" as well as "snapping the throttle open" were both used, though it remains unknown (at least to me) exactly what throttle opening rate each phrase refers to or what rate Mr Rowley employed. Do they refer to opening the throttle in 0.1 sec, 1 sec or 2 seconds, each of which IMHO would lead to dramatically different results.

Thus the following thoughts relate to the test method and conclude with some modern day roll-on results with a stock unmuted 850.

Rowley's RPM Regime

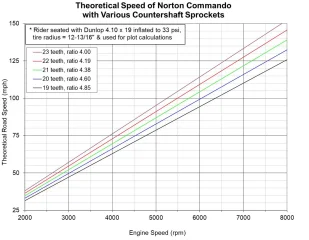

To start let's try to get a better handle on the possible engine rpm that Rowley explored. Using my '74 850 fit with 20 tooth countershaft sprocket as a model (was this the std sprocket they were shipped with?, don’t know, but somebody here does) the following plot was created.

The plot suggests that for my specific bike, Rowley would have been exploring an rpm regime from ~ 2400 to 3600 rpm. Within experimental error, my tach and speedo agree favorably with the plot data.

Roll-on Rates and 40-60 MPH Time Intervals

At times I operate a motorcycle in a fashion similar to Rowley, i.e., rolling on lots of throttle at 40 mph, so if this is what he was doing it is not an unrealistic test to me. I don't instantly roll to full throttle, but yet get there in a second or 2. Do I snap the throttle open in 0.1 sec? NO! Have I turned the throttle from a 40 mph cruising speed to full throttle in 1-2 sec? All the time. I figure the least you can do for the poor bike is to afford it the common courtesy of rolling (not snapping) the throttle on, thereby affording the poor beast some vague semblance of the rate a CV carb slide might actuate at, which in turn serves to maintain air velocity and allow a smoother transition between circuits. CV carbs were made for people that like throttle snapping, i.e., those that don't understand optimum throttle modulation, where the carb does it all for you regardless of the butterfly position. That must be why they came on my 78 BMW R100S!

My '74 850 is likely no different than anybody else's, and when cruising at 2000 rpm in high gear, will pull up cleanly without a stutter or blubber if the throttle is opened at a reasonable rate, i.e., perhaps 2 seconds to full throttle.

Several people made the point previously that dyno runs with A/F ratio monitoring is the best/only way to understand Rowley's solution, and I wouldn't argue that point. I was nevertheless curious to see how my freshly tuned bone stock '74 850 would operate in a test similar to Rowley's.

Some might ask "what does this have to do with Rowley's muted experiment?" Nothing. "Then why would you waste your time thinking and experimenting with such a subject?" Because I wanted to know the general time interval required for a decent running 850 to get from 40-60 mph, thereby gaining a better feel for what Rowley was doing and ultimately achieved.

The subject stock bike has points ignition, auto advance, cross-over exhaust header, and peashooters that are straight through, i.e., no intentional restriction other than 3 longitudinal rows of shallow baffle indents that face forward, with 1-3/8" ID and exit. The carbs are stock Amal Mk1 932s with Rowley's magic tube, 4 ring needle with clip in top groove, 106 needle jets and 260 main jets.

A stop watch was used to explore throttle opening rate and it was observed that a throttle can be snapped open in ~ 0.1 sec, opened comfortably in slightly over a second (1-1.2 sec), or opened very leisurely in 2 sec. Roll-ons from 40-60 mph were timed using different throttle opening rates, where at least a dozen runs were undertaken at each rate. Is the experiment perfect and can the rate of throttle opening be repeated exactly on each run? Of course not. Can a fairly decent job of getting the throttle open at the desired rates of 0.1, 1 sec or 2 sec time interval be achieved? Absolutely!

The slowest roll-on resulted in the shortest acceleration times which fell between 3.8 and 5.0 seconds. In this slow roll-on test, the bike was often over 50 mph before the throttle was 1/2 open. Likewise, the intermediate throttle opening rate gave acceleration times of ~ 4.0 to 5.2 sec. On some of these intermediate opening rate runs, there was a single hiccup occurring earlier in the run that momentarily slowed the acceleration process, thus resulting in the slightly longer times. The throttle snap sequence provided the slowest runs that tended to fall between 5.5 and 7.0 seconds. During all the throttle snap runs the engine behaved exactly like one would predict, it instantly lost fire as if both plug wires were pulled, yet very quickly gathered itself and yanked like hell up to 60 mph. This lag in circuit transitions accounts for the longer acceleration times associated with throttle snaps.

All in all I was surprised at how quickly our stock bikes cover the 40-60 mph interval, and especially how quickly they hit 50 mph - almost as soon as the throttle was eased on. For whatever reason, my intuition was that Rowley's test required a considerably longer time interval, but if his test bike gearing was like mine, suspect it was likely on the order of 5 seconds give or take.

Lastly, if Mr Rowley was snapping the throttle open, I'd be stunned if the bike actually pulled through with zero hesitation, but only he could inform on that front. It would be interesting to know more about "the test" and if his results relate or agree with the results reported here. Perhaps if Mr Rowley is reading this he might provide his thoughts to us by posting here or by sending them to me or a moderator for posting.

Would also be interested to hear from others that might be so inclined as to time a few roll-ons with different rates of throttle application to see if the time intervals or engine responses are similar or vastly different.

Last edited: