Larry S

VIP MEMBER

- Joined

- Apr 15, 2020

- Messages

- 709

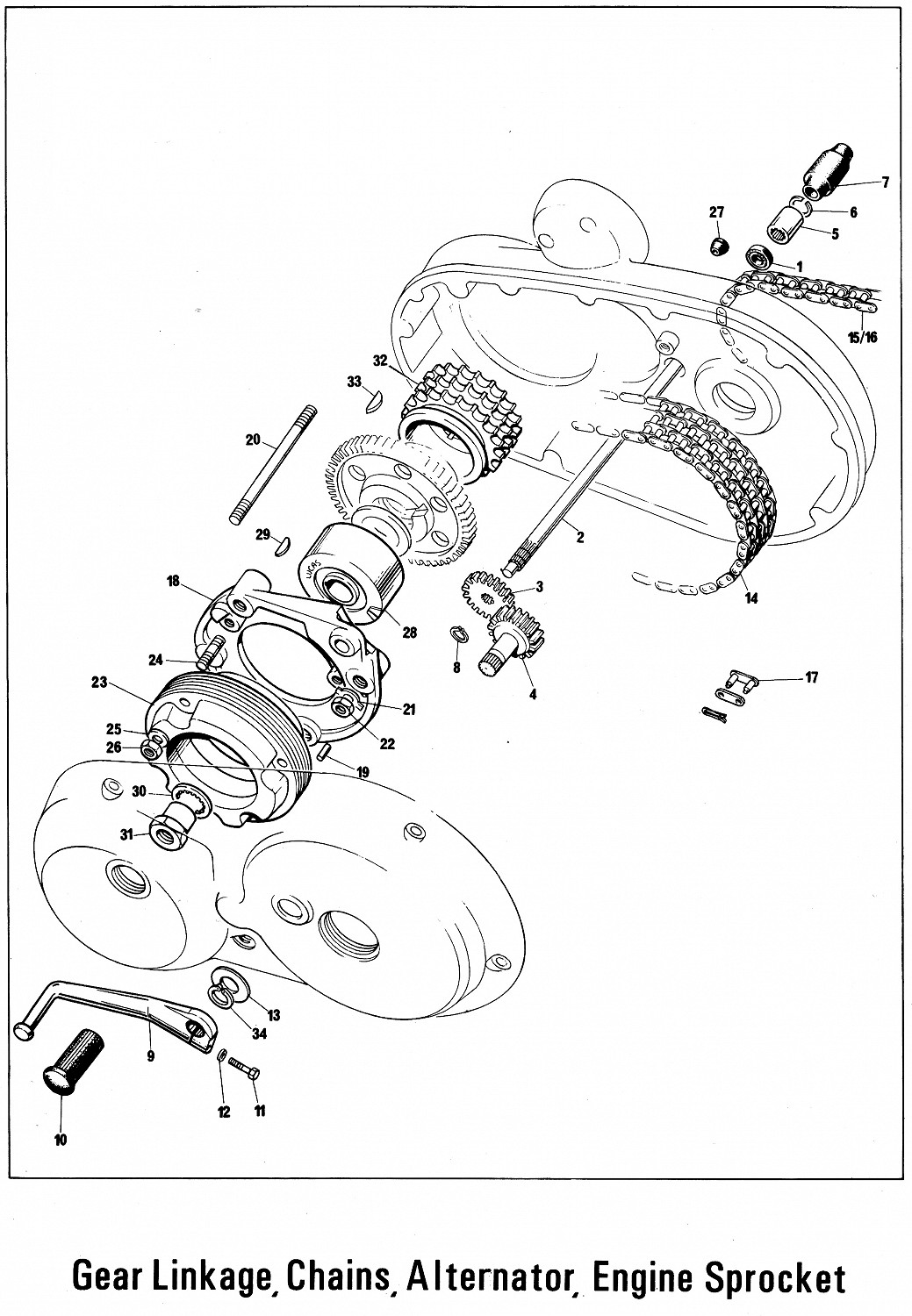

Went for a ride the other day and when I returned home I saw oil leaking from the bike. Upon further inspection it was determined that the oil was leaking from the inner primary gasket. It was easy to find the cause as the lower cradle/engine mounting bolt was snapped off and the middle bolt was loose. While dismantling the primary I also found that the chaincase steady stud was broken. Oh, and did I mention that my brand new right side silencer broke also? Enough with the crying and on with the repairs.

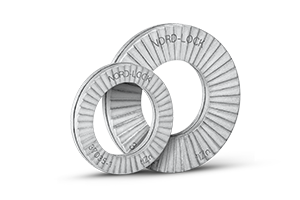

I ordered all brand new hardware and gaskets from Morris Place on Tuesday and received them today (Thursday). That is a quick delivery. I’m going to install everything tomorrow. The question I have is, should I use loctite on the threads? I’m thinking yes and blue. Any other tips or ideas? I’m going to take my silencer to my welder to see what he can do about welding it up. It broke perfectly at weld. We’ll see. After I get everything else put back together I would like to know if I’ll mess anything up with riding with just the headers with no silencers. I have read that you can burn up your exhaust valves if your headers are too short or too large of a diameter. Something about cold air hitting the valves ruining them. I didn’t completely understand it but it seems valid. Thoughts?

Thanks for all the help.

I ordered all brand new hardware and gaskets from Morris Place on Tuesday and received them today (Thursday). That is a quick delivery. I’m going to install everything tomorrow. The question I have is, should I use loctite on the threads? I’m thinking yes and blue. Any other tips or ideas? I’m going to take my silencer to my welder to see what he can do about welding it up. It broke perfectly at weld. We’ll see. After I get everything else put back together I would like to know if I’ll mess anything up with riding with just the headers with no silencers. I have read that you can burn up your exhaust valves if your headers are too short or too large of a diameter. Something about cold air hitting the valves ruining them. I didn’t completely understand it but it seems valid. Thoughts?

Thanks for all the help.