Thanks for visiting Access Norton

- Guest view limit reached

- Create a free account (more details)

- Already a member? Click here to login

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kenny Dreer's 355 lb street tracker

- Thread starter jseng1

- Start date

- Status

- Not open for further replies.

An 880 in decal only !

So if we change the rods, the pistons, the head, the cams and the crank that just leaves the crankcases as the weak link.

Change those too and you are almost set to go rev that extra 1000 rpm.

There's just the $6000 TTI box to order!

So if we change the rods, the pistons, the head, the cams and the crank that just leaves the crankcases as the weak link.

Change those too and you are almost set to go rev that extra 1000 rpm.

There's just the $6000 TTI box to order!

Last edited:

Matchless

VIP MEMBER

- Joined

- Dec 23, 2010

- Messages

- 1,281

That's exactly what I did when building the 920, including the crankcases. I just wanted a Commando that would hopefully NEVER break. Had to sell my Venom to fund it though.An 880 in decal only !

So if we change the rods, the pistons, the head, the cams and the crank that just leaves the crankcases as the weak link.

Change those too and you are almost set to go rev that extra 1000 rpm.

There's just the $6000 TTI box to order!

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 22,700

That was my objective too Martyn.

And it’s worked. I’ve done lots of track days on mine and regularly rev it to 7,000 which inevitably means that sometimes I go over that (one cannot look at the tacho all the time) plus it’s done road miles, albeit not that many. And it’s never leaked a drop, lost a screw or failed to perform apart from once when an o ring in the FCR carbs failed (the only Japanese parts on the bike)! I’m frankly quite staggered at how good the Maney stuff is and only regret not doing it years ago.

Its being retired as my main track bike and will be more road focused from now. So far that has entailed changing the clip ons for Vincent flats. Next will be pod filters instead of open stacks. With the Vincent bars and rearsets it feels very nice on the road. Practically a Goldwing.

And it’s worked. I’ve done lots of track days on mine and regularly rev it to 7,000 which inevitably means that sometimes I go over that (one cannot look at the tacho all the time) plus it’s done road miles, albeit not that many. And it’s never leaked a drop, lost a screw or failed to perform apart from once when an o ring in the FCR carbs failed (the only Japanese parts on the bike)! I’m frankly quite staggered at how good the Maney stuff is and only regret not doing it years ago.

Its being retired as my main track bike and will be more road focused from now. So far that has entailed changing the clip ons for Vincent flats. Next will be pod filters instead of open stacks. With the Vincent bars and rearsets it feels very nice on the road. Practically a Goldwing.

Last edited:

grandpaul

VIP MEMBER

- Joined

- Jan 15, 2008

- Messages

- 13,896

There is no "Tongue In Cheek" emoticon available.Were they that bad ?

grandpaul

VIP MEMBER

- Joined

- Jan 15, 2008

- Messages

- 13,896

That problem came about from the oil in frame.From what I've read they were that bad.

There was a pristine 880 for sale here some years ago. The price was very fair and I nearly went for it.

Reading about the blow ups put an end to that!

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 22,700

Care to expand ?That problem came about from the oil in frame.

grandpaul

VIP MEMBER

- Joined

- Jan 15, 2008

- Messages

- 13,896

I seem to recall him saying that certain modes of operation resulted in oil starvation; foggy memory on that, though...Care to expand ?

- Joined

- Nov 26, 2009

- Messages

- 3,381

Not necessarily. When you reduce the reciprocating weight and associated stresses - the cases and crank are less likely to fail and then a stock crank is OK on a hot street bike if you radius the PTO shaft. But all bets are off if you go full race on the track. I've had my hot street cafe 750 up to 8200 RPM as a one time test and have no problem going to 7000 or 7500 when wringing it out. My lightened stock cranks with radiused PTO shafts and lightened pistons survived my racing abuse but the 850 cases needed reinforcing or they would crack.An 880 in decal only !

So if we change the rods, the pistons, the head, the cams and the crank that just leaves the crankcases as the weak link.

Change those too and you are almost set to go rev that extra 1000 rpm.

There's just the $6000 TTI box to order!

Early desparate attempts to lighten stock 750 pistons for racing back in 1983-4, the crowns were also lightened (nothing blew up).

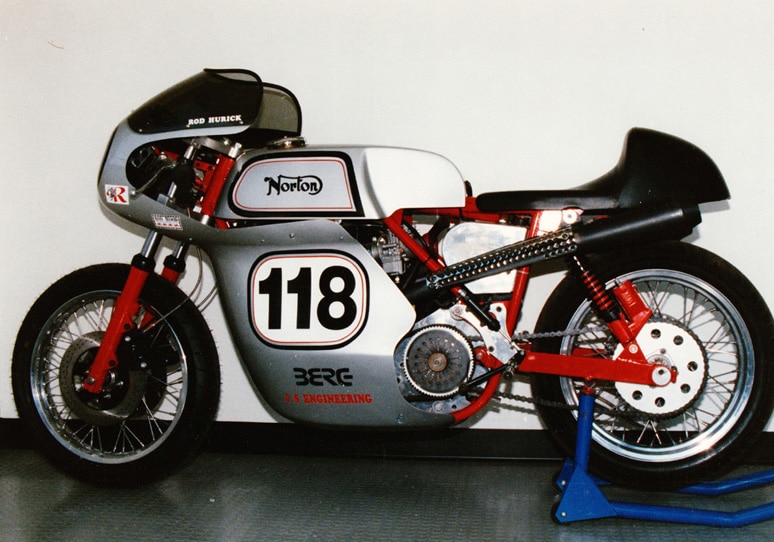

Kenny said he is using leftover parts from his 880 projects on the bike in the photo - hence the 880 side panel decal and other 880 similar items (I forgot to mention that).

****************************************************

I seem to recall him saying that certain modes of operation resulted in oil starvation; foggy memory on that, though...Care to expand ?

**********************************************************

CNW had a similar oiling problem when they tried to run oil in a Commmando frame. Then Comstock added a separate collection bottle as a work around.

What does work is to run the oil return line to the front of the large main frame tube and then a line from the rear of the tube into the oil tank - this allows your frame to act as an oil cooler as in the racer I built for Rod H in the 1980s.

Last edited:

Schwany

VIP MEMBER

- Joined

- Apr 22, 2020

- Messages

- 3,663

Little off topic: I was told by a person that manufactures Manx and Norton cases, that the old Norton twin cases really don't break that often. He may have been referring to street bikes because I told him that is what I am building, but he builds race performance parts, so I'm not sure. Anywho, he talked me out of buying new cases. That really happened.

While I've got the ear of you knowledgeable hot dogs... (well the ones that don't have me on their ignore list)

On a belt clutch is the belt running over the clutch gear self aligning? For example could the clutch be positioned 1/8" closer to the gearbox than typical and the belt stay on the clutch gear and not run off and get shredded?

While I've got the ear of you knowledgeable hot dogs... (well the ones that don't have me on their ignore list)

On a belt clutch is the belt running over the clutch gear self aligning? For example could the clutch be positioned 1/8" closer to the gearbox than typical and the belt stay on the clutch gear and not run off and get shredded?

Re the TEC Triumph shocks. I read a few Triumphrat reviews on these.

Most were written within a week of install and we're very positive. Apparently the stock shocks on the air cooled 790/865 Bonnies are quite awful.

The TEC are an improvement on awful.

One report was after 20,000 kms. At that point the TEC shocks were done, oil leaking out of both and no damping effect remaining. That owner felt that the TEC shocks never were very good, just marginally better than the horrid stock shocks.

When the TEK shocks died he installed IKON 7610s and felt that those shocks worked far better than the TEK Shocks did when new.

Glen

Most were written within a week of install and we're very positive. Apparently the stock shocks on the air cooled 790/865 Bonnies are quite awful.

The TEC are an improvement on awful.

One report was after 20,000 kms. At that point the TEC shocks were done, oil leaking out of both and no damping effect remaining. That owner felt that the TEC shocks never were very good, just marginally better than the horrid stock shocks.

When the TEK shocks died he installed IKON 7610s and felt that those shocks worked far better than the TEK Shocks did when new.

Glen

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 22,700

The belt is self aligning IF the pulleys are in line.Little off topic: I was told by a person that manufactures Manx and Norton cases, that the old Norton twin cases really don't break that often. He may have been referring to street bikes because I told him that is what I am building, but he builds race performance parts, so I'm not sure. Anywho, he talked me out of buying new cases. That really happened.

While I've got the ear of you knowledgeable hot dogs... (well the ones that don't have me on their ignore list)

On a belt clutch is the belt running over the clutch gear self aligning? For example could the clutch be positioned 1/8" closer to the gearbox than typical and the belt stay on the clutch gear and not run off and get shredded?

Ideally you want the belt to run right up to the inner edge of the clutch pulley.

If the belt is running towards the out edge it puts a far greater load on the mainshaft, and a far greater force on the clutch drum when the clutch lever is pulled in which will impact clutch action etc.

- Joined

- Jun 8, 2013

- Messages

- 64

Jim, thanks for that info on tires & rims, I went out and stuck an old 19" XS650 front wheel on my project and it does look better, the 18" now looks to small and is actually almost 1" smaller in diameter than the 18" rear with tires fitted, old GT501's.Here's the tire sizes:

Front tire - 100/90 x 19 Dunlop K180 WM4 rim

Rear tire - 120/90 x 18 Dunlop K180 WM4 rim

Looking back at Kenny's bike makes me think I need to order up a 19" front, it will also help fill the gap between front tire and frame down tubes better as frame was designed for 19" front and rear but I guess I thought I knew better at one time. Kenny's bike just looks right and for me the visual is important.

- Joined

- Jun 8, 2013

- Messages

- 64

My C&J swing arm measures 1" x 1 3/4" x .058" wall and measures 11" inside to inside...Triumph application but appears similar. MarkGP, Thank you for your info. My next year's project is set!

As you obtained one S/A from Kenny, can you please quote dimensions of the box section (H x W x thickness)? How wide is the swinging arm inside? The shock mounting is favourable.

I guess each vernier "nut" acts on the inner bearing race, compressing it against a stepped spindle and allowing the outer race to float in the swinging arm boss. It's my understanding Kenny left the S/A bushes in place for transfer of axial loads.

There has to be some way of shimming and sealing the S/A -- cradle joints.

The advantage of using a ball or roller bearing is absence of the oiling chamber(s) needed for the plain bushes, is it ? I have some difficulty figuring out another advantage of a ball bearing at this location.

- Knut

I just noticed Kenny's rear tail/brake/blinker LED tail light strip adhered to his rear frame loop, I put the same one on my little Surron dirt bike, never ridden behind myself so not sure how effective it is but it functions well and appears rather bright in the garage.

Last edited:

- Joined

- Jun 8, 2013

- Messages

- 64

edited post for tail lite info

- Joined

- Jun 8, 2013

- Messages

- 64

Sorry but made a mistake, the S/A is 11" outside to outside so is 9" inside to inside, I knew there was an 11" somewhere but just measured to be sure.My C&J swing arm measures 1" x 1 3/4" x .058" wall and measures 11" inside to inside...Triumph application but appears similar. Mark

I just noticed Kenny's rear tail/brake/blinker LED tail light strip adhered to his rear frame loop, I put the same one on my little Surron dirt bike, never ridden behind myself so not sure how effective it is but it functions well and appears rather bright in the garage.

Matchless

VIP MEMBER

- Joined

- Dec 23, 2010

- Messages

- 1,281

Now I can finally post pictures easily here is my rear set gear linkage I promised to post. It's basically a copy of the works bikes, only in bolt on form. It means that the lever is at the perfect angle.

Attachments

cliffa

VIP MEMBER

- Joined

- May 26, 2013

- Messages

- 4,428

That's very neat Martyn !! (and worth waiting forNow I can finally post pictures easily here is my rear set gear linkage I promised to post. It's basically a copy of the works bikes, only in bolt on form. It means that the lever is at the perfect angle.

- Joined

- Jan 14, 2004

- Messages

- 2,675

Very Nice!!!Now I can finally post pictures easily here is my rear set gear linkage I promised to post. It's basically a copy of the works bikes, only in bolt on form. It means that the lever is at the perfect angle.

Someone should market that..

- Status

- Not open for further replies.