- Joined

- Aug 19, 2021

- Messages

- 1,455

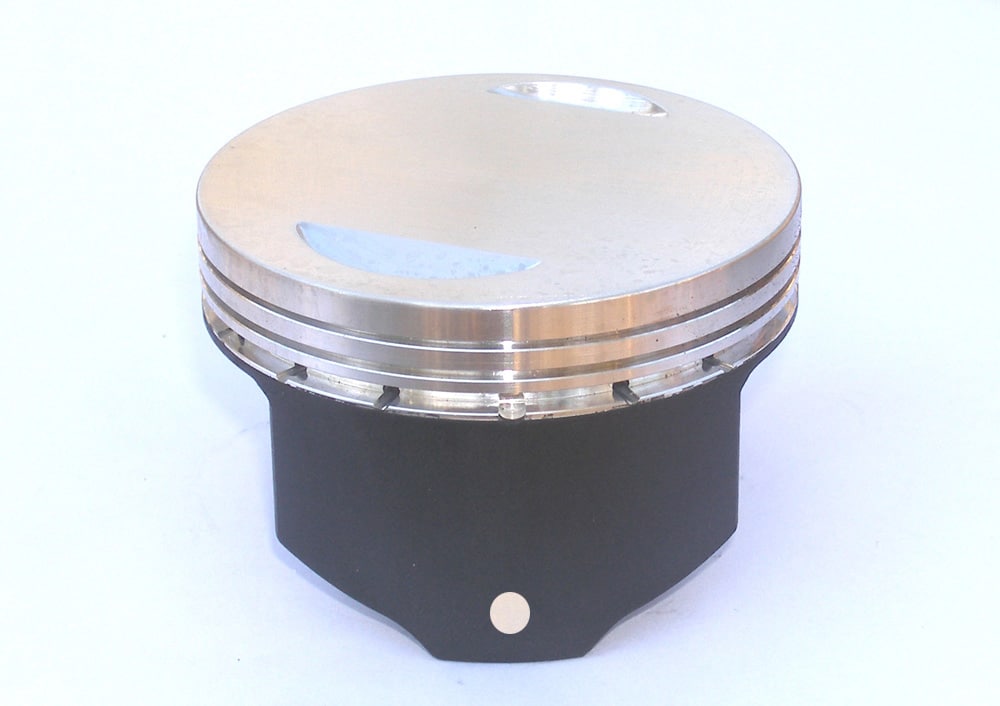

With a .021" copper shim under the cylinders the JS pistons are .125" above the cylinder deck.

The quench pad in the combustion chamber is .123" recess. With .035" fire ring gasket compressed height. there is only .033" clearance between the piston crown and head deck. Too close for my comfort.

The quench pad in the combustion chamber is .123" recess. With .035" fire ring gasket compressed height. there is only .033" clearance between the piston crown and head deck. Too close for my comfort.

Last edited: