- Joined

- Mar 7, 2020

- Messages

- 3,156

I replaced mine due to excessive clutch movement, but found the mainshaft was worn too and needed replacing...

On a bike with allegedly 20k miles....

On a bike with allegedly 20k miles....

Yes, and as noted the spacer locks over the circlip and the shims are for clutch drum to engine sprocket alignment, adjusted to ensure a straight run for your triplex chain.

And, sort of irrelevant after L.A.B.s post, but on the pre Commando short mainshaft gearbox on the shelf in my workshop I can see the phosphor bronze bush end maybe 1/16" in from the sleeve gear outer end.

Yeah, I'm hoping for the best.I replaced mine due to excessive clutch movement, but found the mainshaft was worn too and needed replacing...

On a bike with allegedly 20k miles....

When you pull the transmission out check that it has a two piece roller bearing on the layshaft on the opposite end to the KickstartThanks. At this point, with the play I have, I'd be surprised to find anything in there.

I'll pull the transmission today and find out though.

The cable/ internal cam should have been fine (until, of course, the cable broke). And when I replaced the repaired cable the cam was moving like it should have.If it is feeling like the lever has locked up, the cam that the cable fits into inside the transmission has likely slipped down out of position, quite common if the cable is disconnected and the clutch adjuster screw is removed to facilitate the use of the clutch spring compressor.

What do you have for a shop manual?

The cable/ internal cam should have been fine (until, of course, the cable broke). And when I replaced the repaired cable the cam was moving like it should have.

When it happened, the response of the clutch plates wasn't exactly "locked". At the lever I had almost a "soft" resistant pull until a stop, but it's hard to explain. I have never quite felt it before (on any bike/ ever). Shutting the bike off half way through the ride I couldn't get the clutch plates to open enough to not have the bike jerk and stall when shifting from neutral. I had to ride it down a hill, the bike running and in neutral, and shift into first while I was rolling -- then ten miles later was when I started having more problems and then the cable broke.

Thanks/ will do.When you pull the transmission out check that it has a two piece roller bearing on the layshaft on the opposite end to the Kickstart

Check that the main shaft output bearing is tight in the case

Check for any cracks between the layshaft bearing housing and the output bearing housing

Always replace the circlip that the clutch spacer sits against

If you had a tab washer on the clutch retaining nut throw it away and just use loctite

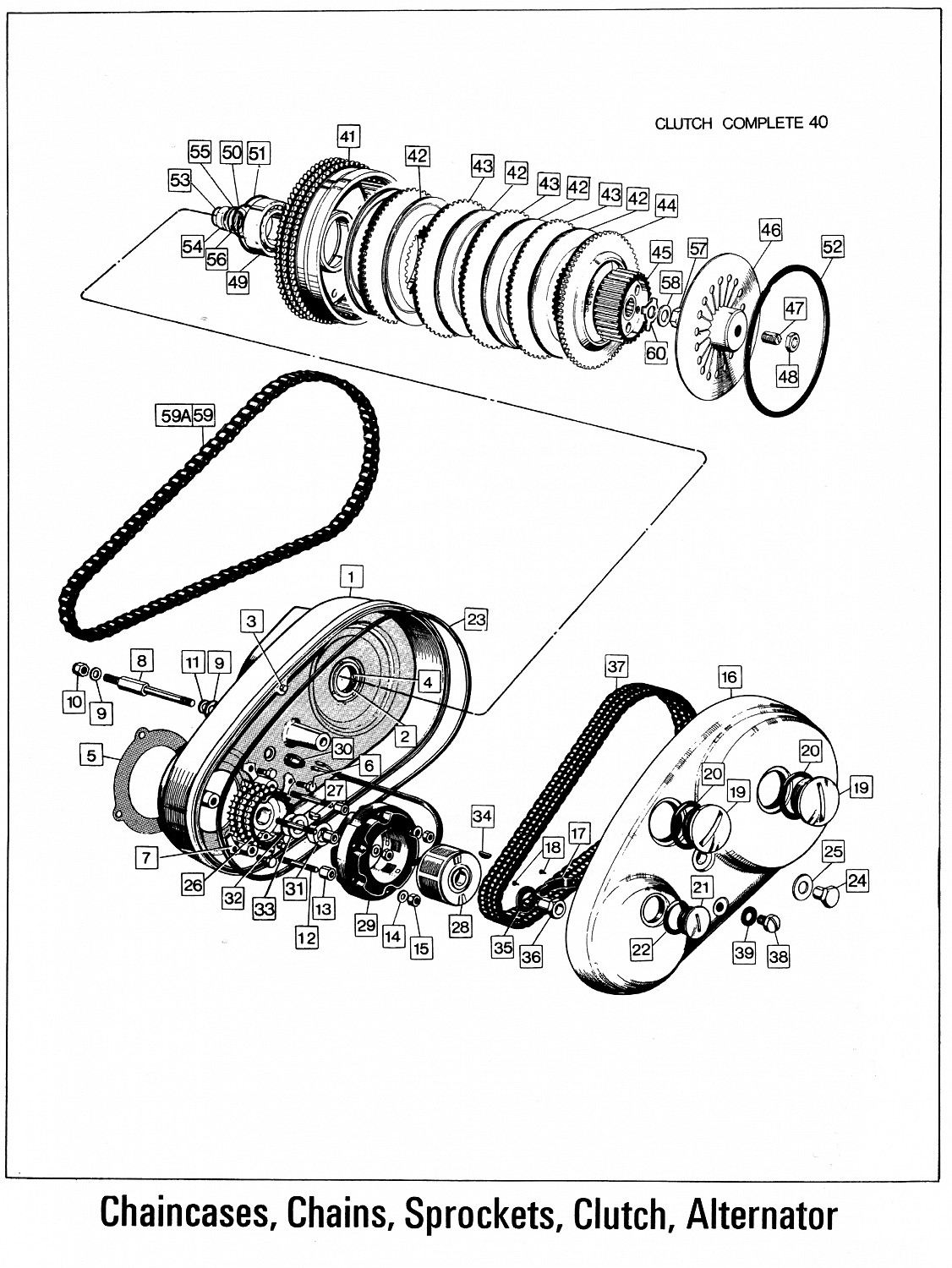

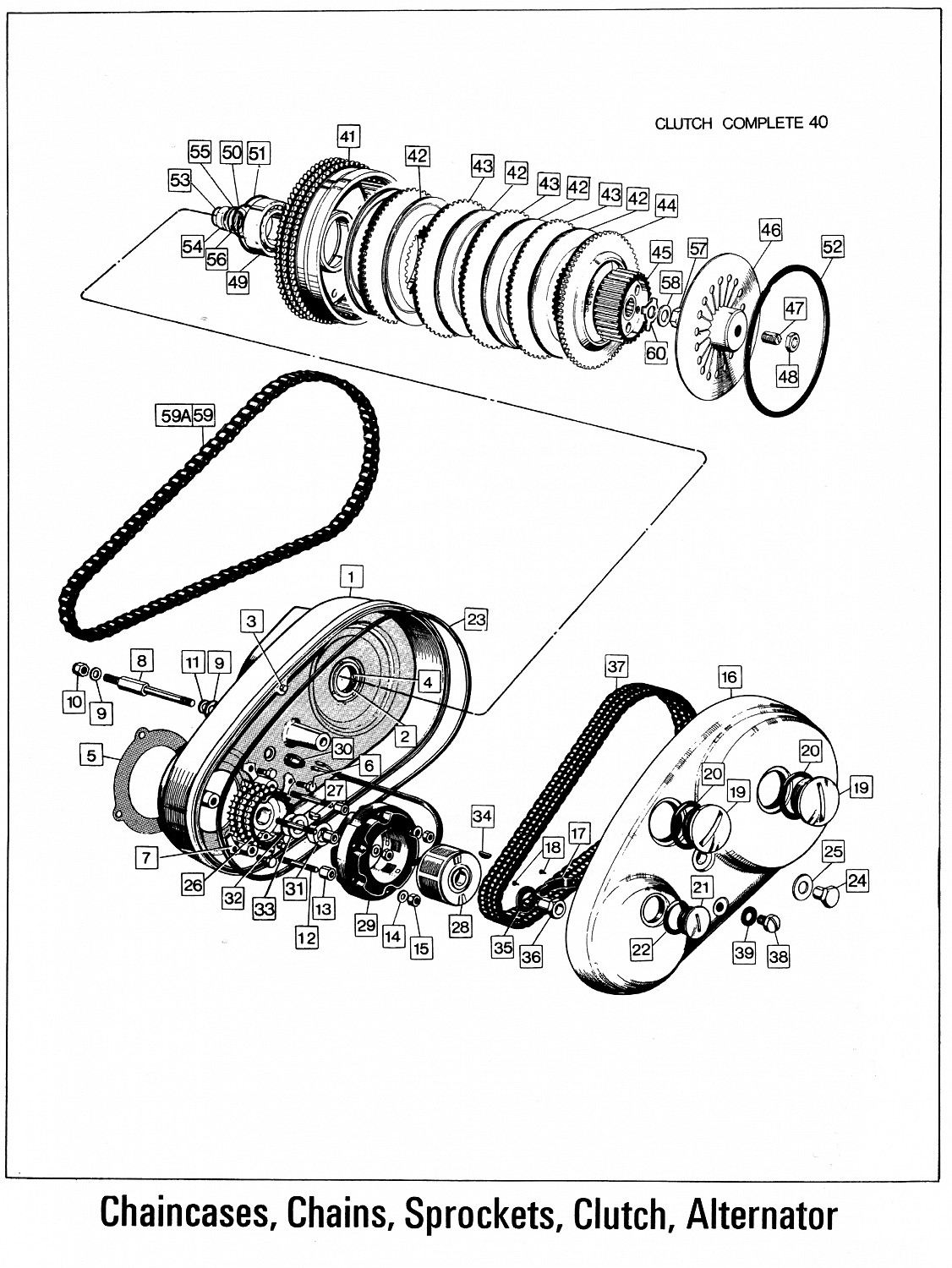

Yes, the clutch nut was loose -- movable, but trapped within the center tab washer (which had opened up a little).Was the clutch nut (57) loose?

Andover Norton Parts Drawings - Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.andover-norton.co.uk

If not, then the nut (26) at the opposite end of the mainshaft might be?

Andover Norton Parts Drawings - Andover Norton Factory Parts - Commando Parts

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.andover-norton.co.uk

The clutch tab washer is too soft and the nut works it way way looseYes, the clutch nut was loose -- movable, but trapped within the center tab washer (which had opened up a little).

As far as I can remember yesPulled the shaft -- not a trace of either bushing. Minimal scoring on I.D. and shaft though.

View attachment 81663

And so I'm clear, two bushings (@1.2") are used?

https://steadfastcycles.com/product...ing-1-2-long-bush?_pos=1&_sid=a0eaadf63&_ss=r

ThanksAs far as I can remember yes

a suitably fat feeler gauge would have established no bushes from the start.Thanks