You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are Amal Premiers any good?

- Thread starter jimbo

- Start date

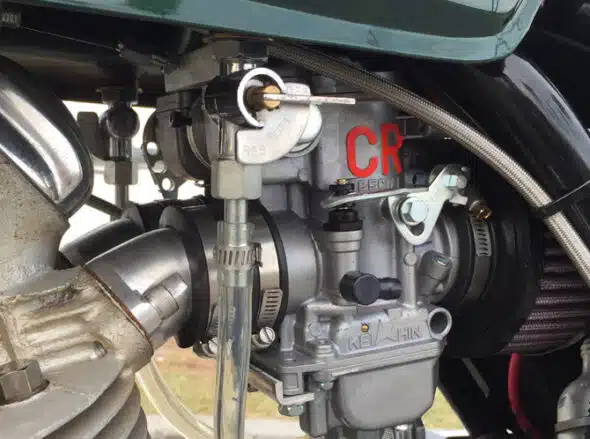

Burlen does not produce the rubber-mounted Amal Mk 1.5 any longer, the Mk2 Concentric is available however. Unfortunately, it has a bad reputation for being difficult to tune properly when fitted to a Norton. A smoothbore version is not available. Apart from the Keihin CRS carb offered by JS Motorsport and the very expensive Keihin FCR offered by CnW, which other options are there that have been tried and tested? How about DellOrto? Their rubber-mounted PHF1 carb comes in suitable sizes and is of compact design, which makes it a viable option to the Mk1 Concentric from a geometrical point of view. It is also cheaper than the current asking price for the Concentric Mk1. I think it is worth looking into.The real issue is that any solid mounted carbs vibrate hard on a Norton . Then wear ( vibration ) . The answer is rubber mounting . I'm running the Wassell pair equivalent and happy . Next carbs / carb ... will be rubber mounted .

But:

The amount of squirt on the phf and phm can be adjusted down , my old B33 has a phf30 it was quite rich when you reved it , I just reset the pump screw , it's getting a phf36 soon which might help the 600cc .

- Knut

Last edited:

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,089

How does rubber mounting carbs on a rubber mounted engine work?

If I took a stick and rubber mounted a carburettor on the end and shook the stick the carb would move more than a carb solidly mounted

I can't imagine a pair of amal carbs sitting dead still on an engine constantly moving for and aft unless the rigidly mounted to the frame ?

If I took a stick and rubber mounted a carburettor on the end and shook the stick the carb would move more than a carb solidly mounted

I can't imagine a pair of amal carbs sitting dead still on an engine constantly moving for and aft unless the rigidly mounted to the frame ?

Good point. What we have here is a dual mass dynamic system. Depending on the spring stiffness and the inherent damping, in a certain range of excitation (rpm) the carb *might* vibrate more, in the remaining range it won't. Cylinder of rubber which is free to deform is short, while mass of the carburettor is comparatively high. This will usually give a low eigenfrequency. The eigenfrequency of the isolastic mounted engine occurs at approx. 2500 rpm (262 Hz). I doubt there will be an excitation of the carb, but it depends on the rubber composition, its thickness, and length of the sleeve.How does rubber mounting carbs on a rubber mounted engine work?

If I took a stick and rubber mounted a carburettor on the end and shook the stick the carb would move more than a carb solidly mounted

I can't imagine a pair of amal carbs sitting dead still on an engine constantly moving for and aft unless the rigidly mounted to the frame ?

- Knut

concours

VIP MEMBER

- Joined

- Dec 29, 2011

- Messages

- 9,570

We have a winner.How does rubber mounting carbs on a rubber mounted engine work?

If I took a stick and rubber mounted a carburettor on the end and shook the stick the carb would move more than a carb solidly mounted

I can't imagine a pair of amal carbs sitting dead still on an engine constantly moving for and aft unless the rigidly mounted to the frame ?

The low frequency/high amplitude vibration is destructive in different ways from high frequency.

The big, soft rubber mounts on my Rotax PowerTek 800 snowmobile engine allow it to jump around crazy at idle. The rubber reed valve carb mounts are really stressed. They fail.

Big airbox (mounted to the carbs) as well. I tucked a big car wash sponge between the airbox & chassis, for at least a placebo level damping.

Last edited:

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,089

So are you saying it could vary from bike to bike depending on ISO setup , rubber composition,etc ?Good point. What we have here is a dual mass dynamic system. Depending on the spring stiffness and the inherent damping, in a certain range of excitation (rpm) the carb *might* vibrate more, in the remaining range it won't. Cylinder of rubber which is free to deform is short, while mass of the carburettor is comparatively high. This will usually give a low eigenfrequency. The eigenfrequency of the isolastic mounted engine occurs at approx. 2500 rpm (262 Hz). I doubt there will be an excitation of the carb, but it depends on the rubber composition, its thickness, and length of the sleeve.

- Knut

Also carburettor weight could be a factor, I'm thinking of the lightweight aluminium amals ?

Influence by the ISO setup will likely be negligible, unless rubber specs are way off and iso not shimmed/pretensioned to spec.

Carburettor weight, rubber composition of sleeves, and their design will have an impact on that system's eigenfrquency (f1).

It's the ratio of eigen frequencies f1/f2 which determines the response.

Let's assume the iso mounted engine has an eigenfrequency of f2 = 262 Hz and f1 = 75 Hz. The frequence ratio becomes 0.286 .

If f2 is reduced to 230 Hz (corresponding to a vibration peak at 2200 rpm), the frequency ratio changes to 0.326 (+14%).

On the other hand, if f1 changes from 75 Hz to 100 Hz, the frequency ratio changes to 0.382 (+34%).

Hence, your attention should be on the carburettor and it's mounting.

As a rule of thumb, frequency ratios below 0.1 or greater than 10 are unaffected of excitation by the main system (i.e., the engine).

Between 0.1 and 1, and between 1 and 10, the excitation by the main system grows exponentially (at f1/f2 = 1 the response is infinite, i.e., the subsystem collapses),

so it's desireable to steer the ratio towards low numbers.

- Knut

Carburettor weight, rubber composition of sleeves, and their design will have an impact on that system's eigenfrquency (f1).

It's the ratio of eigen frequencies f1/f2 which determines the response.

Let's assume the iso mounted engine has an eigenfrequency of f2 = 262 Hz and f1 = 75 Hz. The frequence ratio becomes 0.286 .

If f2 is reduced to 230 Hz (corresponding to a vibration peak at 2200 rpm), the frequency ratio changes to 0.326 (+14%).

On the other hand, if f1 changes from 75 Hz to 100 Hz, the frequency ratio changes to 0.382 (+34%).

Hence, your attention should be on the carburettor and it's mounting.

As a rule of thumb, frequency ratios below 0.1 or greater than 10 are unaffected of excitation by the main system (i.e., the engine).

Between 0.1 and 1, and between 1 and 10, the excitation by the main system grows exponentially (at f1/f2 = 1 the response is infinite, i.e., the subsystem collapses),

so it's desireable to steer the ratio towards low numbers.

- Knut

Last edited:

milfordite

VIP MEMBER

- Joined

- Feb 13, 2012

- Messages

- 316

I ran rubber mounted Dellorto's on my race Norton. They worked well. I installed a spring that was tethered to the tops of the carbs back to the engine. That solved any problems with the weight of the carbs hanging off the manifolds. Simple yet effective.

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,089

Was that in a commando chassis ?I ran rubber mounted Dellorto's on my race Norton. They worked well. I installed a spring that was tethered to the tops of the carbs back to the engine. That solved any problems with the weight of the carbs hanging off the manifolds. Simple yet effective.

If so did you try it with and without rubber mounts?

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,073

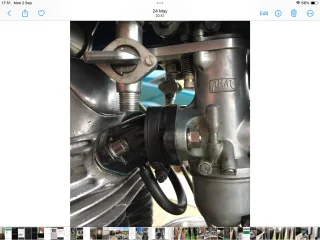

Norton AMAL MK1 carbs could be rubber mounted like the 69 and later Triumph 650/750 twins.

Instead of the standard 99.0522 (thin) o-ring, you use the much thicker 70.9711 o-ring and the rubber washers and cups shown here:

The Norton carb studs would likely need to be modified.

This method is not nearly as flexible as rubber manifolds, but it does remove at least some vibration from the carbs. You can feel the frame of a running 69 & later Triumph 650/750 twin and then the carbs and feel the difference.

IMHO and layperson thinking, engine shaking is not nearly as important as the higher frequency vibration which can froth the fuel. I assume that this is why Triumph went to this mounting method.

Instead of the standard 99.0522 (thin) o-ring, you use the much thicker 70.9711 o-ring and the rubber washers and cups shown here:

Triumph Parts Drawings - Genuine Triumph Factory Parts - Commando Parts -

Andover Norton Parts are the only Norton spare parts in the market manufactured to original drawings, within the factory-approved tolerances, from the correct materials, and with the correct finish.

andover-norton.co.uk

The Norton carb studs would likely need to be modified.

This method is not nearly as flexible as rubber manifolds, but it does remove at least some vibration from the carbs. You can feel the frame of a running 69 & later Triumph 650/750 twin and then the carbs and feel the difference.

IMHO and layperson thinking, engine shaking is not nearly as important as the higher frequency vibration which can froth the fuel. I assume that this is why Triumph went to this mounting method.

rubber mounting Amal’s , is so easy , quick to remove carbs , cooler carbs , mine runs better smoother tick over , why do you think all other manufacturers rubber mount ? Drag your Norton into the 21st century , they are made to be ridden not kept as museum pieces

Attachments

marshg246

VIP MEMBER

- Joined

- Jul 12, 2015

- Messages

- 5,073

I suppose it's easy if you have the hardware to do it - where did you get it?rubber mounting Amal’s , is so easy , quick to remove carbs , cooler carbs , mine runs better smoother tick over , why do you think all other manufacturers rubber mount ? Drag your Norton into the 21st century , they are made to be ridden not kept as museum pieces

o0norton0o

VIP MEMBER

- Joined

- Apr 27, 2015

- Messages

- 2,075

Someone explain what rubber mounting changes...

If the claim is that the carb is secured to the frame to vibrate less and attached by a rubber tunnel to the isolastic engine moving around, then you are claiming that the rubber intake is flexing and changing shape to allow the engine to move and the carb to remain steady. So much for the shape of the intake track being important..

If you don't secure the carb body to the frame to steady it, then the carb is whipping around on a rubber whip attached to the vibrating engine..... so it's vibrating with the engine anyway....

Or,.... I don't know how to explain it, but I spent money doing it, so it's better... (a standard of proof equal to the claim of passing a Z900 at 140 mph on a commando. Ok, maybe I had a tailwind and was going downhill)

Or, The carbs don't work the same bolted to the manifold as they do mounted on rubber tubes because,...... (Enter your known physics defying explanation here)

If the claim is that the carb is secured to the frame to vibrate less and attached by a rubber tunnel to the isolastic engine moving around, then you are claiming that the rubber intake is flexing and changing shape to allow the engine to move and the carb to remain steady. So much for the shape of the intake track being important..

If you don't secure the carb body to the frame to steady it, then the carb is whipping around on a rubber whip attached to the vibrating engine..... so it's vibrating with the engine anyway....

Or,.... I don't know how to explain it, but I spent money doing it, so it's better... (a standard of proof equal to the claim of passing a Z900 at 140 mph on a commando. Ok, maybe I had a tailwind and was going downhill)

Or, The carbs don't work the same bolted to the manifold as they do mounted on rubber tubes because,...... (Enter your known physics defying explanation here)

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,089

Nobody is saying don't do itrubber mounting Amal’s , is so easy , quick to remove carbs , cooler carbs , mine runs better smoother tick over , why do you think all other manufacturers rubber mount ? Drag your Norton into the 21st century , they are made to be ridden not kept as museum pieces

For my part I can't understand how rubber mounting to something that's shaking can smooth it out ? It can only shake more at some stage because a commandos engine vibration isn't constant

ashman

VIP MEMBER

- Joined

- Jul 11, 2010

- Messages

- 6,090

Vibrations of carbs will wear out the jets and needles over time the needle vibrate which in turn cause the jets to wear oval so rubber mounting the carbs will slow down the jets wearing out, myself just replace the needles and jets every so many years of riding, carb rebuild kits are cheap and keep the Norton running great, just another part of maintenance on our beloved Nortons, I usually do the carbs every 2 or 3 years depends on the miles I clock up each year, has worked for me in the 48+ years of ownership.

Ashley

Ashley

baz

VIP MEMBER

- Joined

- May 26, 2010

- Messages

- 8,089

Yes but the reason carbs are rubber mounted is to stop frothing in the float bowlVibrations of carbs will wear out the jets and needles over time the needle vibrate which in turn cause the jets to wear oval so rubber mounting the carbs will slow down the jets wearing out, myself just replace the needles and jets every so many years of riding, carb rebuild kits are cheap and keep the Norton running great, just another part of maintenance on our beloved Nortons, I usually do the carbs every 2 or 3 years depends on the miles I clock up each year, has worked for me in the 48+ years of ownership.

Ashley

I can understand it working on a rigidly mounted engine

But not on a violently shaking engine in a commando

As an aside from this a very high mileage riding mate of mine always keeps the choke slides in his amals even though he never uses the choke

He claims to get a lot more wear out of them because of the damping effect

johnm

VIP MEMBER

- Joined

- Feb 26, 2008

- Messages

- 1,834

Nice. I made similar but simpler manifolds for a 500 twin in a feather bed frame. A vertical mounted engine so no need for the radius.rubber mounting Amal’s , is so easy , quick to remove carbs , cooler carbs , mine runs better smoother tick over , why do you think all other manufacturers rubber mount ? Drag your Norton into the 21st century , they are made to be ridden not kept as museum pieces

One of several steps to eliminate fuel starvation at the end of long straights.

On a dyno without rubber mounting touching the carbs was like getting an electric shock. Painful.

Last edited:

milfordite

VIP MEMBER

- Joined

- Feb 13, 2012

- Messages

- 316

I was using a featherbed frame. Didn't try solid mounts. These were carbs from my F1B Ducati.Was that in a commando chassis ?

If so did you try it with and without rubber mounts?