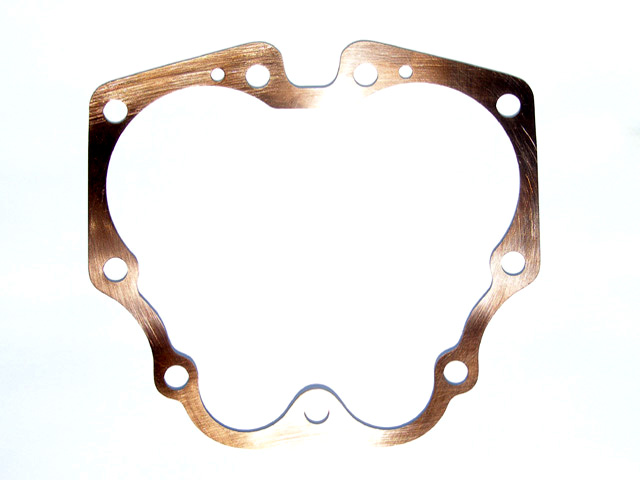

I would also contact Cometic for a base gasket. I know they make them so you might be able to get the exact thickness you need.

Pete

On my 1360 I doubled up standard Cometic .043" base gaskets to get the required squish clearance.

Perfect sealing, gasket and spacer all in one.

Because it is rubber coated, and in my case there are four rubberized surfaces, the gaskets did compress a bit more than a straight metal spacer, so this has to be taken into account.

.086" torqued down to about .075"

On retorque the change was minimal, didn't even require tappet adjustment.

As Pete suggests, a single rubberized base gasket with core thickness at your spec is likely something Cometic would take care of.

Glen

Last edited: