lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,979

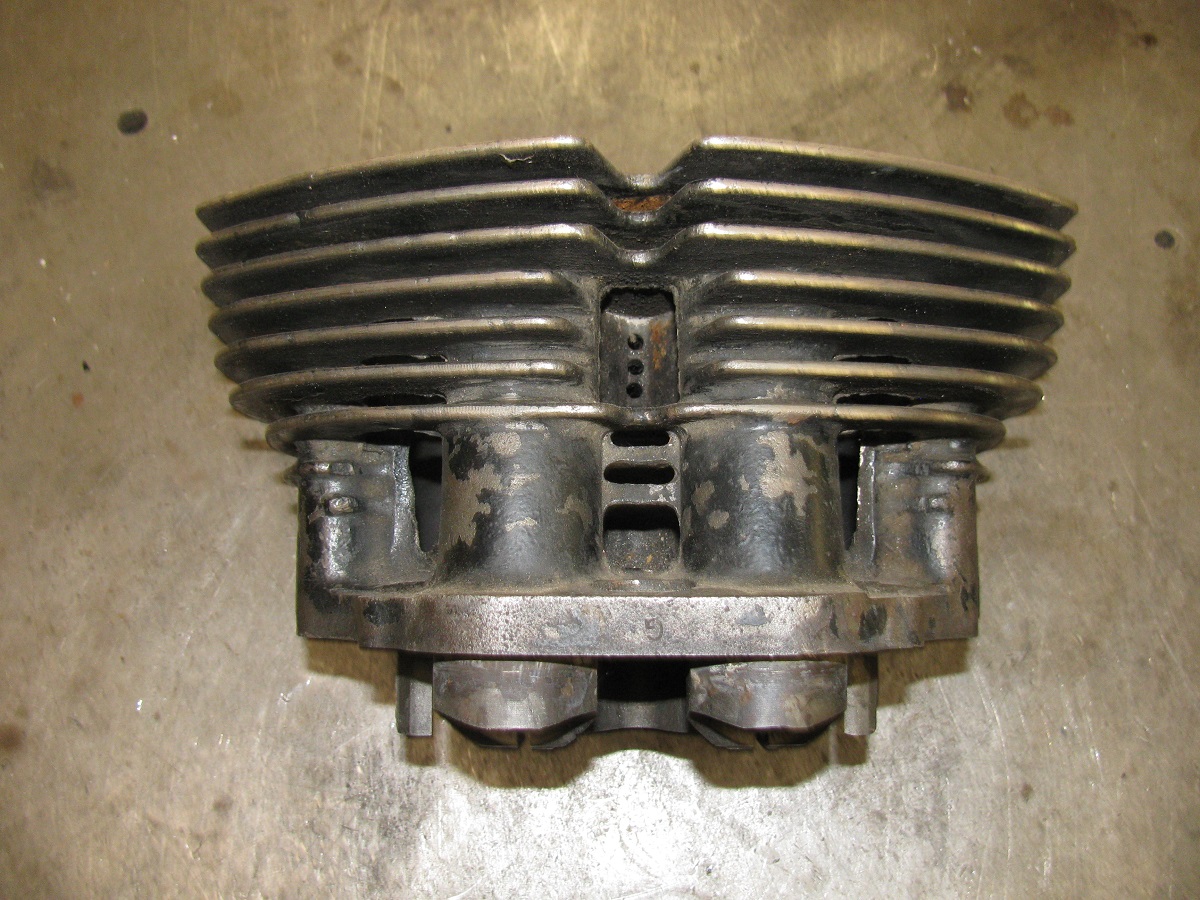

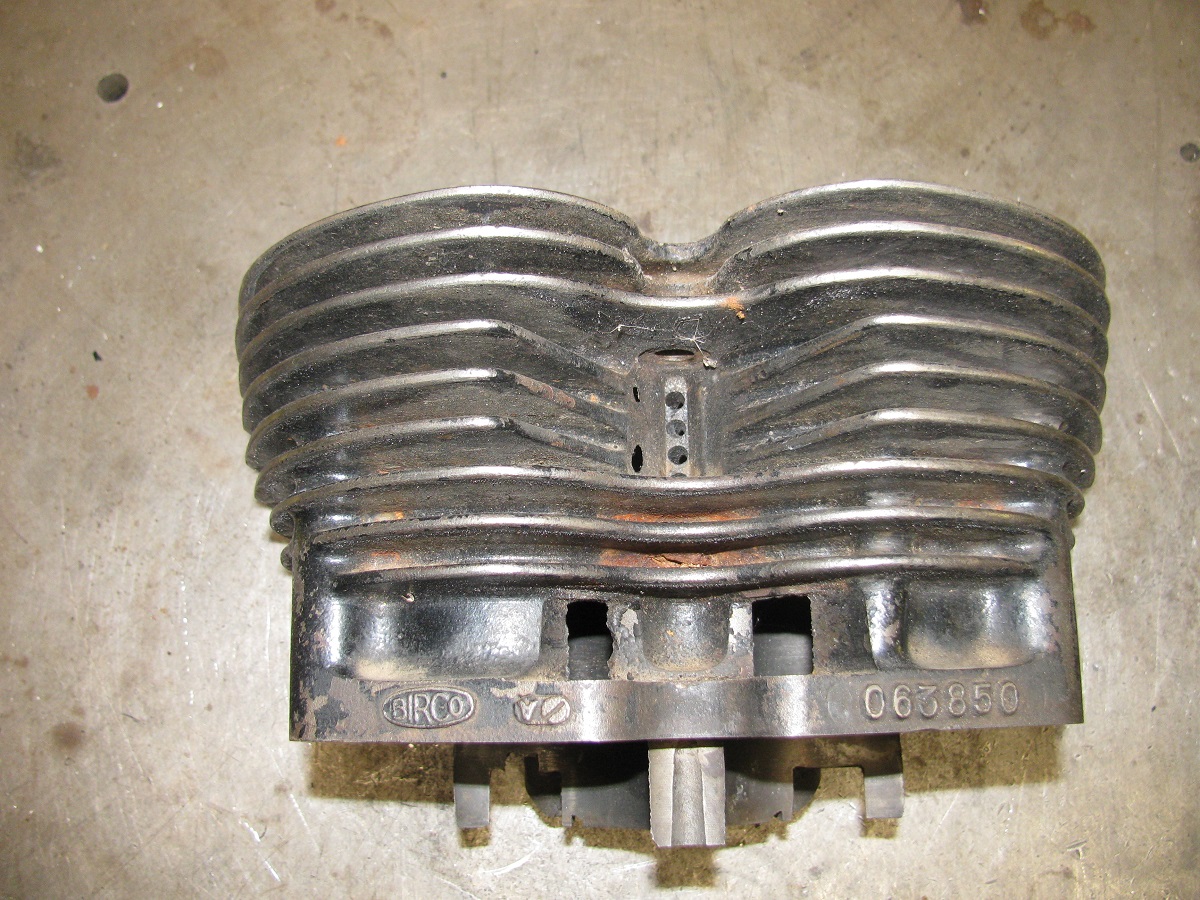

While searching around for some parts today, I ran across an old 920 cylinder from which the liners had been removed. It shows the machining required for the sleeves, but also the extend to which the casting is bored through in several places. I think this is the worst case of daylight showing through that I have seen.

Ken

Ken