p400

VIP MEMBER

- Joined

- Jul 14, 2014

- Messages

- 1,291

Disassembling a 850 Norton for rebuild, to the point of removing pinion gear.

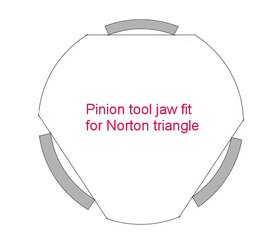

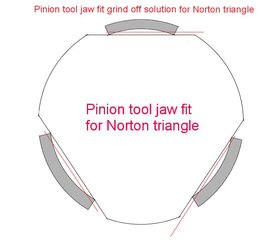

Purchase the silver plated tool and could not get the three jaws to tighten around the pinion, altho when off the shaft seemed to tighten down to the size needed.

Purchased a second tool , not plated black oxide finish because I thought the plating was causing the issue.

Neither tool will close far enough or tight enough to allow pulling the pinion.

What is the issue here? Have others had this same issue ?

Purchase the silver plated tool and could not get the three jaws to tighten around the pinion, altho when off the shaft seemed to tighten down to the size needed.

Purchased a second tool , not plated black oxide finish because I thought the plating was causing the issue.

Neither tool will close far enough or tight enough to allow pulling the pinion.

What is the issue here? Have others had this same issue ?

Last edited: