- Joined

- Aug 19, 2021

- Messages

- 1,364

As I go about dismantling my MK II for a layshaft bearing replacement, I keep encountering gaskets glued to the mating surfaces with some sort of gasket sealer. This not only makes separation of the various components difficult, it leave a mess to scrape off the surfaces.

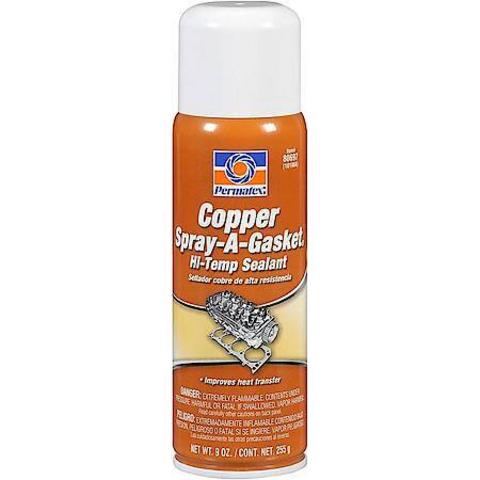

Over the past 45 years I have used spray Coppercoat gasket compound on all of the various machines I have worked on. This includes motorcycles, automobiles and outdoor power equipment. I even use it on head gaskets. I have never had any leaks after placing these various machines into service.

What I like about spray Coppercoat, other than the leak free service, is that although it is tacky aiding in holding the gaskets in place for assembly, it separates upon disassembly without sticking to the mating surfaces. This virtually eliminates any cleanup of the surfaces.

My question is; am I missing something? Is it really necessary to "glue" the gaskets in place for leak free assemblies on a Norton? I find the scraping necessary to remover the glued on residue more likely to damage the finely machined mating surfaces thus promoting the likelihood of leaks.

Over the past 45 years I have used spray Coppercoat gasket compound on all of the various machines I have worked on. This includes motorcycles, automobiles and outdoor power equipment. I even use it on head gaskets. I have never had any leaks after placing these various machines into service.

What I like about spray Coppercoat, other than the leak free service, is that although it is tacky aiding in holding the gaskets in place for assembly, it separates upon disassembly without sticking to the mating surfaces. This virtually eliminates any cleanup of the surfaces.

My question is; am I missing something? Is it really necessary to "glue" the gaskets in place for leak free assemblies on a Norton? I find the scraping necessary to remover the glued on residue more likely to damage the finely machined mating surfaces thus promoting the likelihood of leaks.

Last edited: