- Joined

- Nov 15, 2020

- Messages

- 56

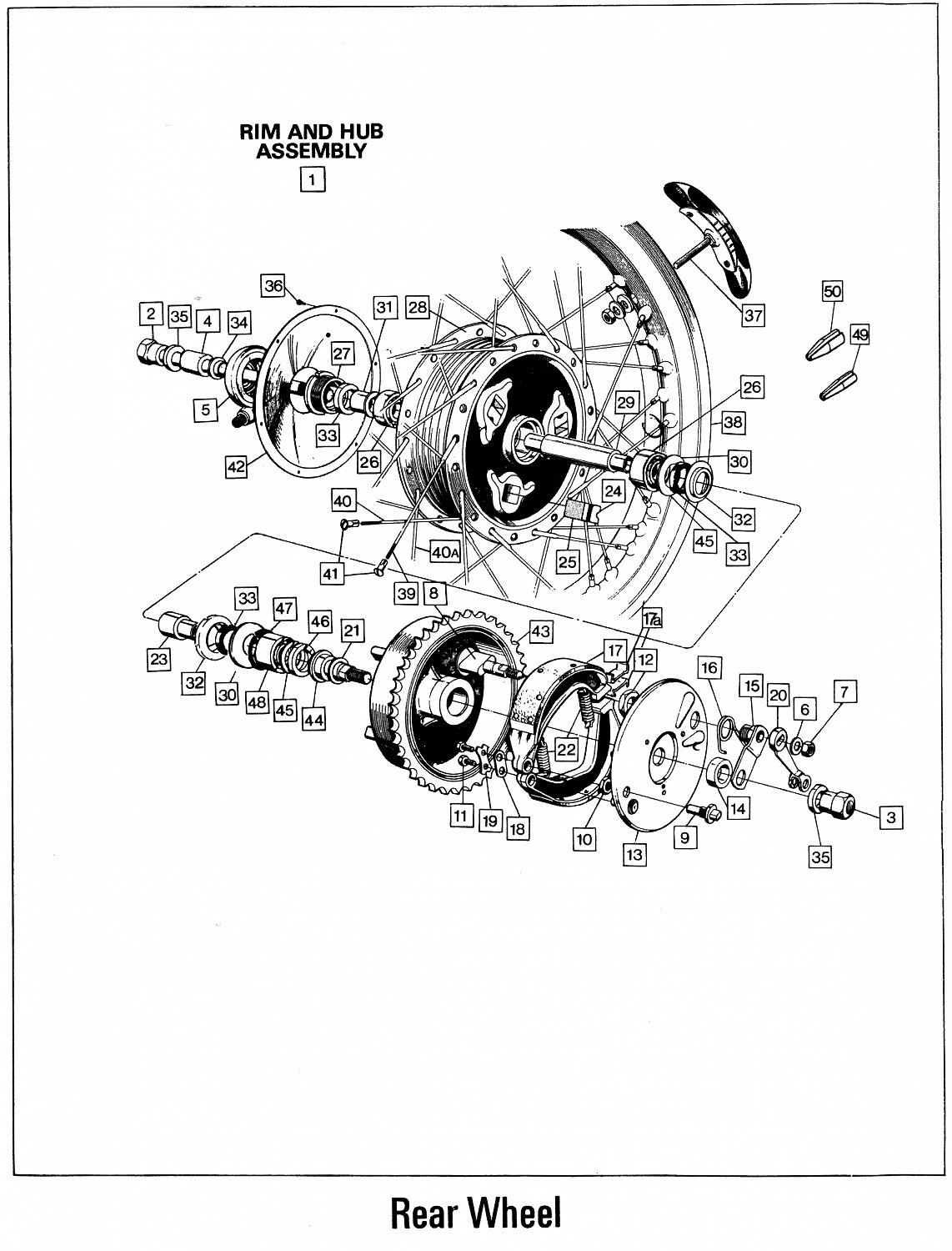

Having a bear of a time taking off rear wheel...am a bit lost

...am a bit lost

the axle will unscrew about an inch, then you have to pull it out.Been turning for 30 minutes...just spinning...

Been turning for 30 minutes...just spinning...

Left side was a little loose when I got it...have right side out about 3 inches but its just spinning..put left side back and the fight side still spinning...tks for response..It's a two piece axle.

1. Make sure left side axle nut is tight.

2. Disconnect speedo cable.

3. Loosen right side axle and remove.

4. Remove right axle spacer.

5. Slide wheel to the right, it will now disengage from drum,sprocket assembly leaving sprocket, chain and brake in place.

6. Lift out wheel.

7. If removal of sprocket/drum is require, disconnect chain, brake cable.

8. Remove left side nut, slide out sprocket/drum/brake assembly unit.

Right side just spinning out about 3 inches...tighten left side back..still have right side out 3 and just spinning..I ran it back in and have repeated that most of the afternoon...not sure how to post photos on her yetBit more detail on where the issue is would be good. Is the axle out as an example.

Timewarp. Ya cant remove that spacer until you have the axle out.

DERECK

If you have 3 inches and the axle turns easily it is only in the bores of the two wheel bearings.

The axle (spindle) doesn't come into contact with the wheel bearings as they locate on the shouldered ends of the bearing spacer.

Motorcycle parts and spares for Norton motorbikes - Genuine Andover Norton Spare Parts - Andover Norton Motorcycles Parts - Original Andover Norton Parts

Motorcycle parts and spares for Andover Norton motorbikes: Andover Norton manufactures and supplies all Genuine Factory Spare Parts for Norton motorcycles built before 2002.andover-norton.co.uk