You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MK3 Restomod

- Thread starter lcrken

- Start date

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,975

That's OK Schwany, I'm a ridiculously optimistic sort. Maybe too much so.  I always assume that I can find some way to fix any mechanical issue if I work at it hard enough. Unfortunately, that isn't always true in the real world. But looking at these kinds of issues as a challenge keeps me a lot happier than complaining about how unfair life is. And if that fails, there's always a good whiskey to improve ones appreciation for life.

I always assume that I can find some way to fix any mechanical issue if I work at it hard enough. Unfortunately, that isn't always true in the real world. But looking at these kinds of issues as a challenge keeps me a lot happier than complaining about how unfair life is. And if that fails, there's always a good whiskey to improve ones appreciation for life.

Ken

Ken

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,648

Ken, this couldn’t have happened to a better person.

Meaning, you will approach it soundly and fix it properly.

For many mere mortals it would be a catastrophe. For you it‘ll no doubt be a minor hiccup!

Carry on.

Meaning, you will approach it soundly and fix it properly.

For many mere mortals it would be a catastrophe. For you it‘ll no doubt be a minor hiccup!

Carry on.

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,975

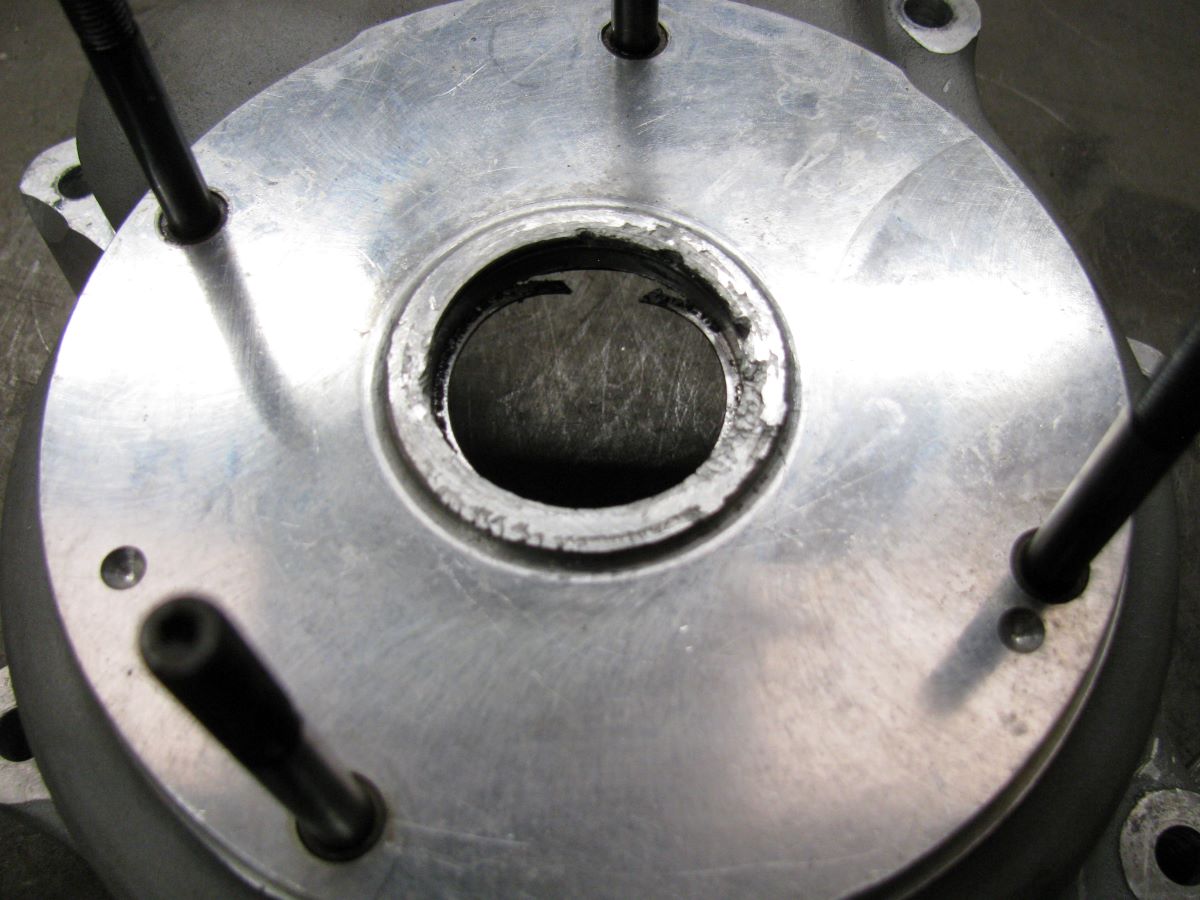

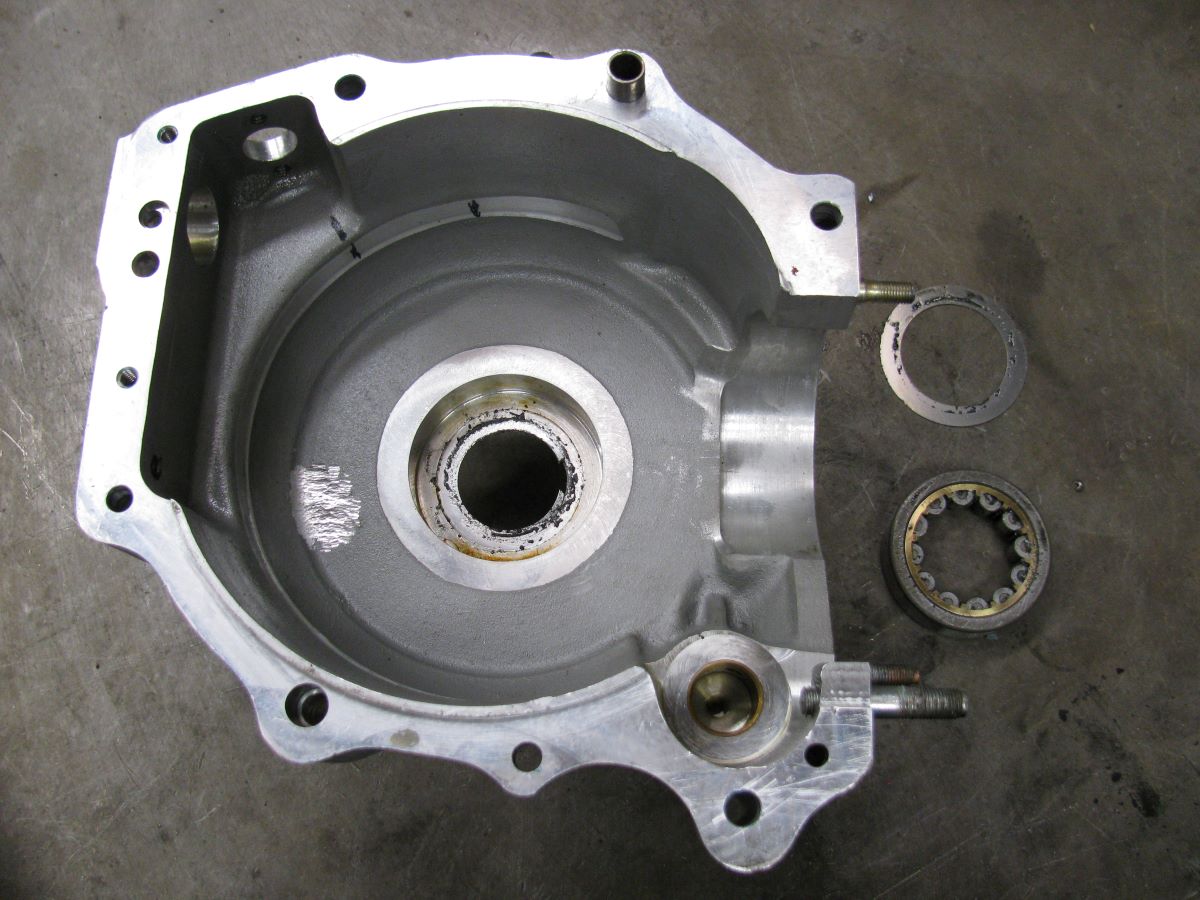

Some more progress. I managed to pull the drive side half off without too much trouble, leaving the rest of the bottom end intact.

These pics show the damage in more detail.

The broken lip is only .033" thick, but after removing the broken ends, there is still maybe 75% of it left. I'm tempted to just fit (very carefully) a new seal, and go with it. I'm reluctant to try welding it up and machining the lip back. My experience with welding the cases in that area is that it shrinks the bearing bore enough that I would have to re-bore it. The other option is to bore out the seal area and fit a machined insert. Decisions, decisions.

Ken

These pics show the damage in more detail.

The broken lip is only .033" thick, but after removing the broken ends, there is still maybe 75% of it left. I'm tempted to just fit (very carefully) a new seal, and go with it. I'm reluctant to try welding it up and machining the lip back. My experience with welding the cases in that area is that it shrinks the bearing bore enough that I would have to re-bore it. The other option is to bore out the seal area and fit a machined insert. Decisions, decisions.

Ken

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,648

That lip is not doing anything other than providing a stop for the seal Ken.

So if 75% of it is left, it’s still fulfilling its role.

Leave it be is my vote.

So if 75% of it is left, it’s still fulfilling its role.

Leave it be is my vote.

- Joined

- Nov 11, 2013

- Messages

- 5,393

The inside of the case half doesn't look too happy at ~8:30

Shelby-Right

VIP MEMBER

- Joined

- Jan 28, 2022

- Messages

- 640

Can you just get it machined off / recessed and and fit a steel plate machined up proper like , with three or 4 counter sunk screws bolting into that thick area around the bearing . Cheers .Some more progress. I managed to pull the drive side half off without too much trouble, leaving the rest of the bottom end intact.

View attachment 99211

These pics show the damage in more detail.

View attachment 99212

View attachment 99213

The broken lip is only .033" thick, but after removing the broken ends, there is still maybe 75% of it left. I'm tempted to just fit (very carefully) a new seal, and go with it. I'm reluctant to try welding it up and machining the lip back. My experience with welding the cases in that area is that it shrinks the bearing bore enough that I would have to re-bore it. The other option is to bore out the seal area and fit a machined insert. Decisions, decisions.

Ken

- Joined

- Apr 6, 2013

- Messages

- 1,405

Ken,

How about a steel (or titanium ) insert with a stepped lip wide enough to cover the damaged face OD after machining out/down the damage?

) insert with a stepped lip wide enough to cover the damaged face OD after machining out/down the damage?

Fixes the current damage and potential for happening again. And better than only .033 thick cast aluminum.

How about a steel (or titanium

Fixes the current damage and potential for happening again. And better than only .033 thick cast aluminum.

Last edited:

Shelby-Right

VIP MEMBER

- Joined

- Jan 28, 2022

- Messages

- 640

Take to a good tool maker type machine shop , they will fix it easy .

- Joined

- Apr 6, 2013

- Messages

- 1,405

Or maybe you could machine in a groove and use a thin C clip to replace the damaged lip...

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,648

I said you’d do it ‘properly’.Lots of good suggestions here. I'm pretty sure at this point that I'm going to go with a machined insert of some sort. I'll post pictures when sorted.

Ken

Me, I’d have done nothing !

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,975

I said you’d do it ‘properly’.

Me, I’d have done nothing !

And you'd probably have been right. I just can't seem to help myself. It's a bit like the "if all you have is a hammer, everything looks like a nail", but in reverse. I have all these nice machine tools, so everything looks like it should be fixed with a complicated machining procedure.

Hey, at least it keeps me busy, and as my dad used to say, off the street and out of the pool halls.

Ken

Fast Eddie

VIP MEMBER

- Joined

- Oct 4, 2013

- Messages

- 20,648

I knew you’d do it ‘right’ Ken !

Looking forward to the next episode…

Looking forward to the next episode…

lcrken

VIP MEMBER

- Joined

- Mar 15, 2009

- Messages

- 4,975

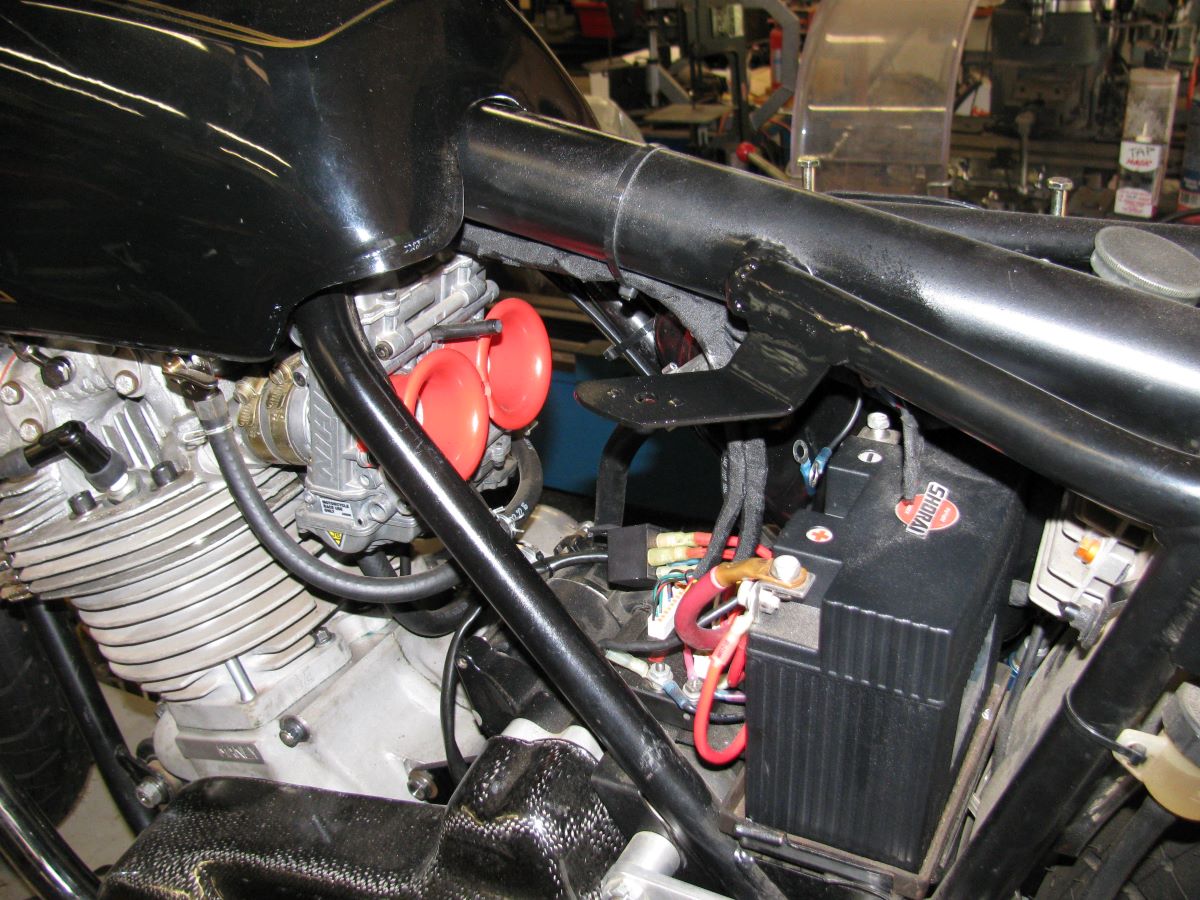

Hard to believe it's been almost a year now. The engine is back together and in the bike, along with almost all the other bits. The wiring harness is finished and wrapped. I spent several hours today making a mounting tab for the left side cover and welding it to the frame. It uses a Dzus fastener in place of the stock Mk3 plastic quick release fastener.

Picture of the side cover tab:

And one of the bike with the cover attached:

I still need to reinstall the Tri-Spark ignition and time it, so I can fire it up again and make sure it runs properly. After that, I need to get the seat upholstered, fab up some sort of air filter arrangement, make a chain guard, sort out a front fender and mounts, run an oil tank breather hose to some sort of catch bottle, rivet the new VIN tag on the steering head, stamp the crankcase with a matching serial number, and it will be ready for a test ride. Actually, I plan to do a test ride as soon as possible, so probably without the fender and chain guard. And I'm sure there will be something I don't expect, that will need dealing with.

Its' good to be back working in the shop regularly again. I've lost a lot of time to serious family issues this year, but life goes on, and I'm getting my life in order again. It's just a bit different life now.

I'm making a serious effort to have the bike running and sorted in time for the local SoCal Norton club Hansen Dam ride in November. Looking forward to that.

Ken

Picture of the side cover tab:

And one of the bike with the cover attached:

I still need to reinstall the Tri-Spark ignition and time it, so I can fire it up again and make sure it runs properly. After that, I need to get the seat upholstered, fab up some sort of air filter arrangement, make a chain guard, sort out a front fender and mounts, run an oil tank breather hose to some sort of catch bottle, rivet the new VIN tag on the steering head, stamp the crankcase with a matching serial number, and it will be ready for a test ride. Actually, I plan to do a test ride as soon as possible, so probably without the fender and chain guard. And I'm sure there will be something I don't expect, that will need dealing with.

Its' good to be back working in the shop regularly again. I've lost a lot of time to serious family issues this year, but life goes on, and I'm getting my life in order again. It's just a bit different life now.

I'm making a serious effort to have the bike running and sorted in time for the local SoCal Norton club Hansen Dam ride in November. Looking forward to that.

Ken