- Joined

- Oct 28, 2014

- Messages

- 1,860

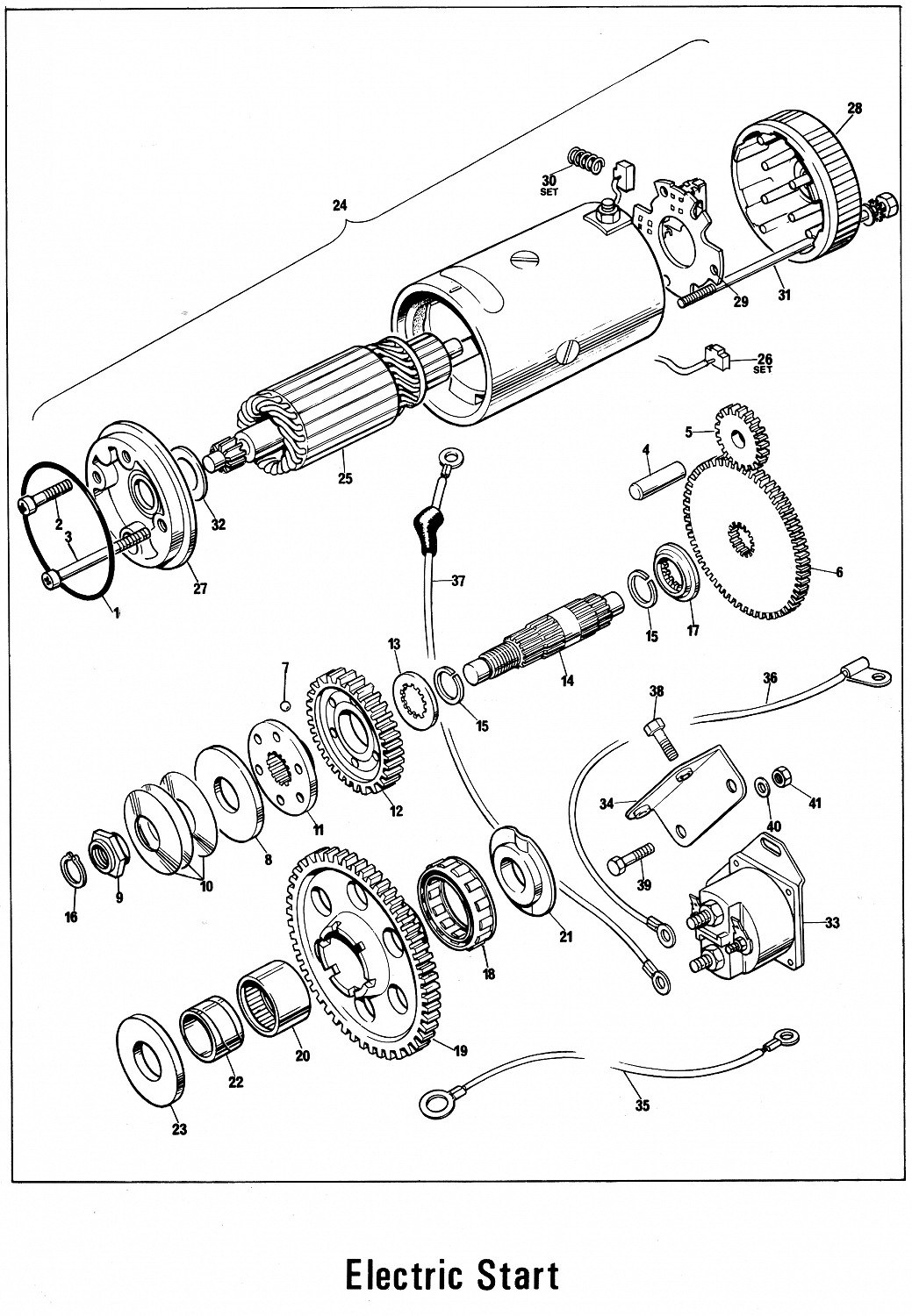

I am replacing a primary chain on a MK3. It was so stretched out that the chain was wearing grooves in the bottom of the primary case and a few other spots. The tensioners were extended a long ways and the slipper pads were coming loose from the shaft. By pads I mean not just the rubber but the entire piece of steel with rubber bonded to it. It FLOPS on the end of the shaft. Disaster was not far off. So I ordered a new pair from OB. The chain is a renolds replacement. I replaced everything with no problem until it came time to install the carrier for the alternator which is also the outrigger bearing for the anti-backfire unit. The shaft was at least 1/8" away from the bearing hole. After much fiddling I could fit shaft A into hole B but the gears would be binding. Test #1, I tried it leaving out the big gear for the sprag clutch. The shaft fit easily into the carrier. It moved freely foreward and backwards and the unit would spin easily. Test #2 I removed the unit ( the anti backfire unit) and tried with just the big sprag gear in place. It moved quite freely also. Test #3 I removed the sprag unit and fit the gear + anti backfire unit and then the carrier. Both had plenty of free movement and I would be happy.

However, when I reinstalled the sprag everything bound up and the shaft was way off from its hole in the carrier.

I have pulled this apart dozens of times and checked every piece for damage or wear but still no clue. With the sprag and gear installed (but no carrier) I can easily turn the gear in one direction (clockwise) with no sense of anything wrong with the sprag . Any ideas?

However, when I reinstalled the sprag everything bound up and the shaft was way off from its hole in the carrier.

I have pulled this apart dozens of times and checked every piece for damage or wear but still no clue. With the sprag and gear installed (but no carrier) I can easily turn the gear in one direction (clockwise) with no sense of anything wrong with the sprag . Any ideas?