- Joined

- Mar 23, 2019

- Messages

- 16

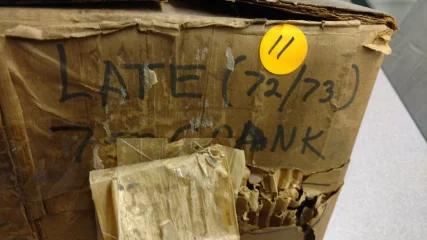

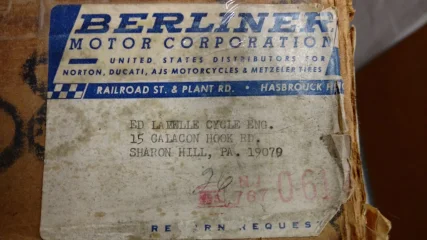

For my engine rebuild I'm about ready to take my scored crank to be reground. The wisdom seems to be that the crank should be dismantled and then assembled sans rotor since the rotor gets in the way of access to the journal faces.

I've looked at several 850 cranks and all have about a tenth of an inch clearance between the outer face e of the rotor and the inner face of the journal. So with a large enough grinding wheel there is a clear shot. Is this the problem...that the grinding wheels are too small?

The reason for poking on this is that I can't just bolt the halfs together since the crank bolts are too long and they protrude over the journal faces. Padding between the two halves with a bunch of washers makes me a bit nervous about just how aligned the assembly would be.

Maybe there are some mega accurate spacers that people use?

I've looked at several 850 cranks and all have about a tenth of an inch clearance between the outer face e of the rotor and the inner face of the journal. So with a large enough grinding wheel there is a clear shot. Is this the problem...that the grinding wheels are too small?

The reason for poking on this is that I can't just bolt the halfs together since the crank bolts are too long and they protrude over the journal faces. Padding between the two halves with a bunch of washers makes me a bit nervous about just how aligned the assembly would be.

Maybe there are some mega accurate spacers that people use?