- Joined

- May 10, 2020

- Messages

- 70

Greetings,

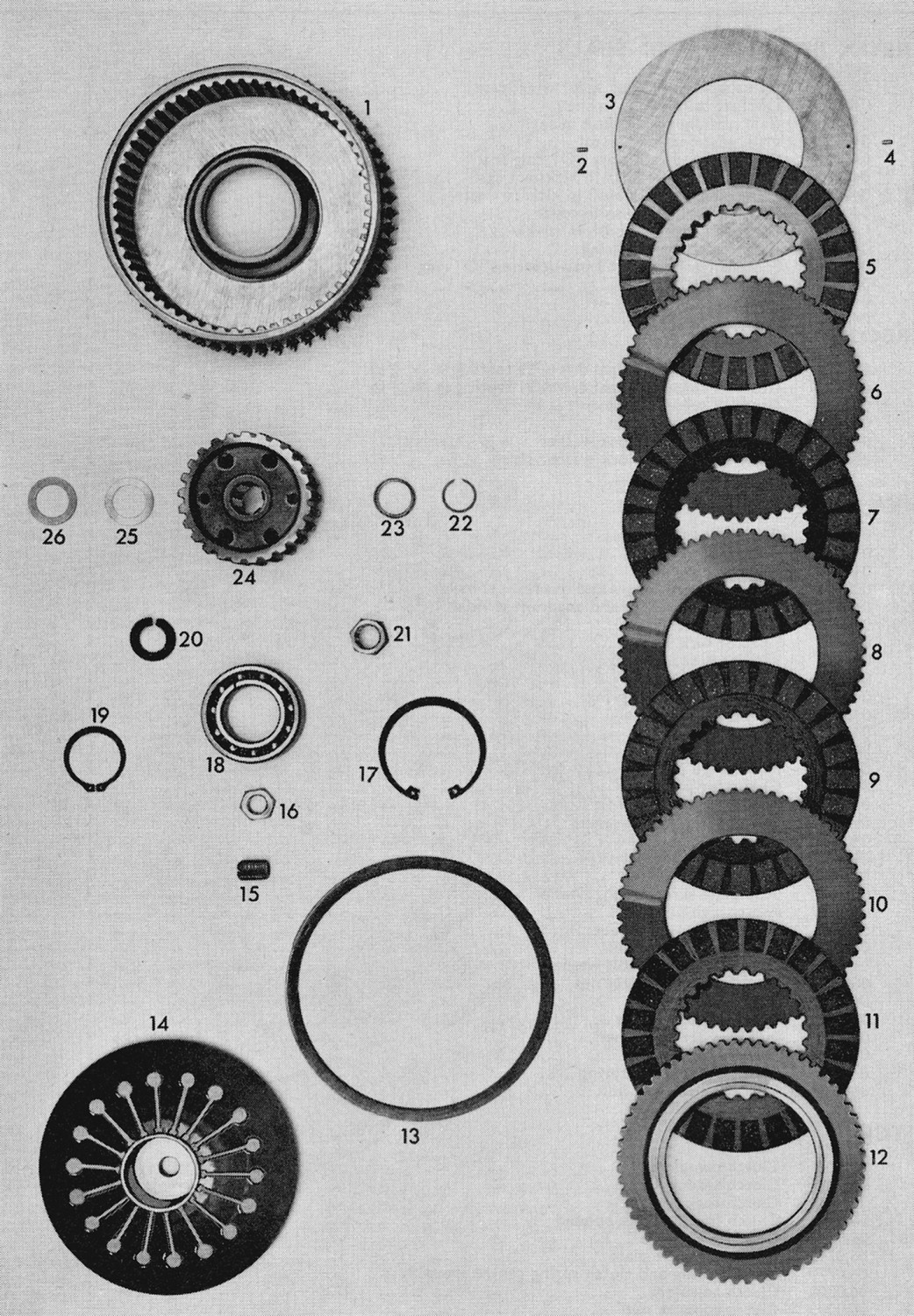

A friend brought me his 70 commando sport, that hasn't ran for 25 years. We got it running, you know the usual, carbs, gas tank, petcocks, and stuck clutch plates. The clutch is extremely hard to pull. We lubed the cable, it didn't help much. We're going to install a new cable. He informed me that he had a different clutch installed years ago, because the stock clutched slipped when he'd get over 100mph (nothing better than good bull shit). Anyway, the clutch that is in the bike has an indexed, first steel plate, indexed with roll pins. I have only worked on my 72 interstate, and triumphs. The parts books list a friction plate first. I have not found a indexed 1st plate listed anywhere. We're going to try the cable fist. I need to change the o ring on the kick start shaft, and I'll investigate actuator when I have that apart as well.

I am wondering if the spring was replaced with the clutch back in the day. He said it was a hard pull back then but it didn't slip. Maybe someone here will know more about what we're dealing with. And perhaps some other things to look for.

Thanks for all replies,

Phil

A friend brought me his 70 commando sport, that hasn't ran for 25 years. We got it running, you know the usual, carbs, gas tank, petcocks, and stuck clutch plates. The clutch is extremely hard to pull. We lubed the cable, it didn't help much. We're going to install a new cable. He informed me that he had a different clutch installed years ago, because the stock clutched slipped when he'd get over 100mph (nothing better than good bull shit). Anyway, the clutch that is in the bike has an indexed, first steel plate, indexed with roll pins. I have only worked on my 72 interstate, and triumphs. The parts books list a friction plate first. I have not found a indexed 1st plate listed anywhere. We're going to try the cable fist. I need to change the o ring on the kick start shaft, and I'll investigate actuator when I have that apart as well.

I am wondering if the spring was replaced with the clutch back in the day. He said it was a hard pull back then but it didn't slip. Maybe someone here will know more about what we're dealing with. And perhaps some other things to look for.

Thanks for all replies,

Phil