- Joined

- Nov 30, 2012

- Messages

- 247

Hi All,

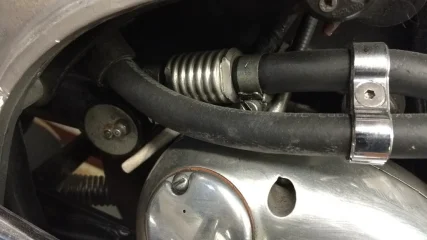

This post is just to share my experience with an anti-wet sump tap (coupled with the ignition circuit), so that you don't make the same mistake as what I did.

I first installed it when my Dominator was still a 88 and then 99 model (500 then 600 cc / 3 start oil pump).

Later on, I switched to a 750 Commando engine / 6 start oil pump, but without cheking that the IN and OUT pipes of the anti-wet sump tap were large enough (i.e. same diameter as the oil tank pipes) to cope with the new oil flow requirements. They were not (about 1/2 the capacity of the oil tank pipes).

Result: a completely worn out RH crankshaft journal due to unsufficient oiling.

Silly isn't it?

So beware of the oil flow capacity of any anti-wet sump device (in addition to the other critical points and pros & cons widely discussed here).

P.S.: to me the good solution is either to live with wet sumping or (what I did) to use Comnoz's reed breather.

Hope this helps,

Laurent

This post is just to share my experience with an anti-wet sump tap (coupled with the ignition circuit), so that you don't make the same mistake as what I did.

I first installed it when my Dominator was still a 88 and then 99 model (500 then 600 cc / 3 start oil pump).

Later on, I switched to a 750 Commando engine / 6 start oil pump, but without cheking that the IN and OUT pipes of the anti-wet sump tap were large enough (i.e. same diameter as the oil tank pipes) to cope with the new oil flow requirements. They were not (about 1/2 the capacity of the oil tank pipes).

Result: a completely worn out RH crankshaft journal due to unsufficient oiling.

Silly isn't it?

So beware of the oil flow capacity of any anti-wet sump device (in addition to the other critical points and pros & cons widely discussed here).

P.S.: to me the good solution is either to live with wet sumping or (what I did) to use Comnoz's reed breather.

Hope this helps,

Laurent