Mofosheee

VIP MEMBER

- Joined

- Aug 4, 2020

- Messages

- 161

Hello Forum

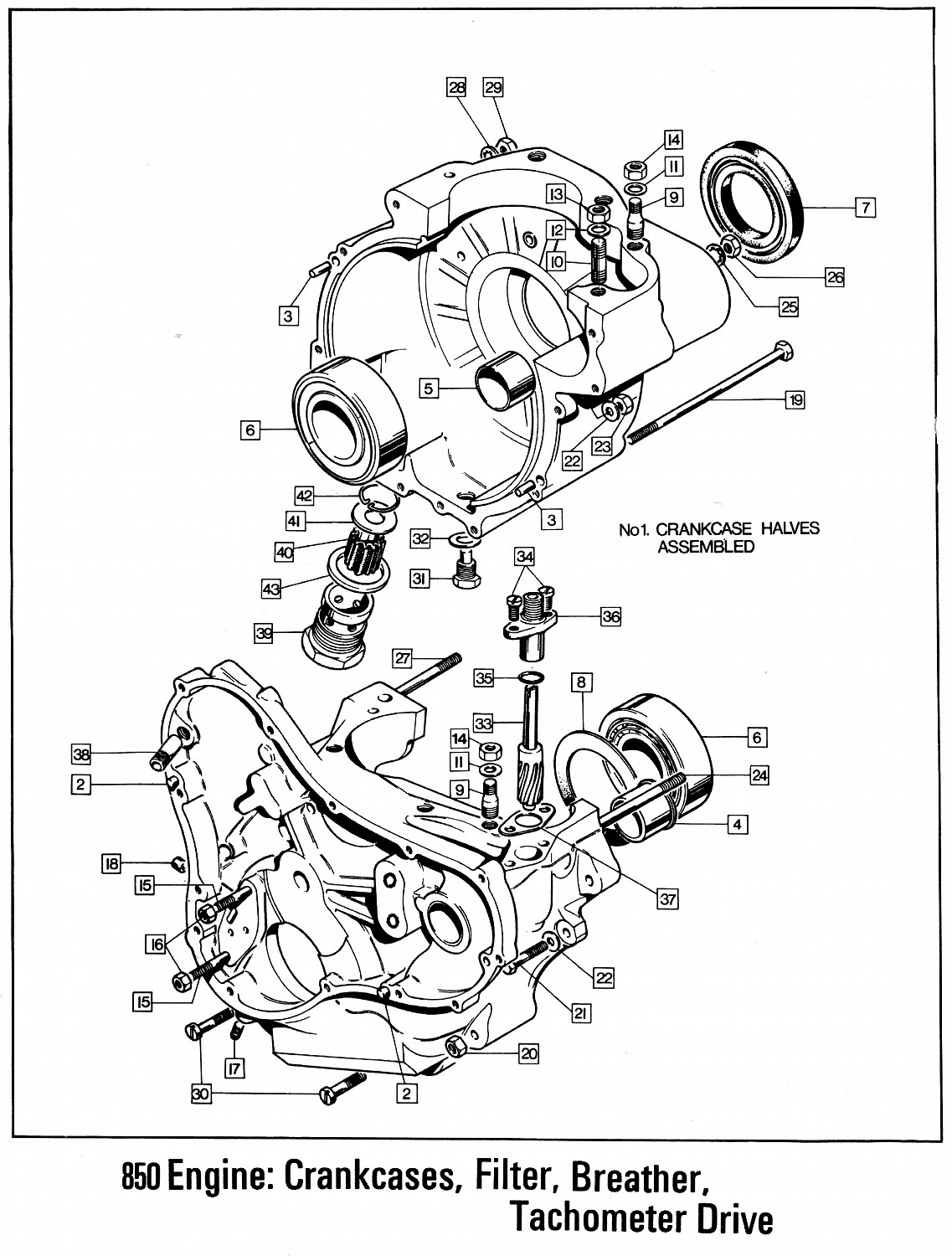

I have an 1973 850 (basket case) Engine disassembled;

Cases have been split and parts cleaned with solvent. Engine had been torn down before. Visually, everything looks good;

bore, cam & lifters, bearings, cases, crank , case threads, etc. Pistons = +0.040" . Cylinder head exhaust threads destroyed (out for repair)

So where to go from here? What will I regret not doing at this point? What not to use or do?

For instance, is there a particular main bearing set to install, crank case ventilation mod, oil sump mod, should I or shouldn't I use stainless cylinder bolt hardware,

preferred gasket set and sealant (I hates leakers)

I know there is a link here regarding my inquiry, but I can't find it. Thanks all

I have an 1973 850 (basket case) Engine disassembled;

Cases have been split and parts cleaned with solvent. Engine had been torn down before. Visually, everything looks good;

bore, cam & lifters, bearings, cases, crank , case threads, etc. Pistons = +0.040" . Cylinder head exhaust threads destroyed (out for repair)

So where to go from here? What will I regret not doing at this point? What not to use or do?

For instance, is there a particular main bearing set to install, crank case ventilation mod, oil sump mod, should I or shouldn't I use stainless cylinder bolt hardware,

preferred gasket set and sealant (I hates leakers)

I know there is a link here regarding my inquiry, but I can't find it. Thanks all