You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1966 Atlas crankcases

- Thread starter pierodn

- Start date

- Joined

- May 28, 2003

- Messages

- 2,590

The hole is not original.

To me all this venting to relieve excessive blow-by is a sloppy method to bypass having to build a quality engine that does not leak. The primary purpose is to increase crank case volume thereby lowering pressure/vacuum cycle.

In my engines I would plug this hole and allow the oil to lube the drive side crank main bearing, chains , gears, intermediate shaft and timing side cam bush as the designers chose.

In the very early 20M3 mid series an original 20 series oil control vent hole was adjusted with an additional hole to lower the oil level due to the engine forward tip of the commando frame. So the engineers were quite aware of the engine oil level.

To me all this venting to relieve excessive blow-by is a sloppy method to bypass having to build a quality engine that does not leak. The primary purpose is to increase crank case volume thereby lowering pressure/vacuum cycle.

In my engines I would plug this hole and allow the oil to lube the drive side crank main bearing, chains , gears, intermediate shaft and timing side cam bush as the designers chose.

In the very early 20M3 mid series an original 20 series oil control vent hole was adjusted with an additional hole to lower the oil level due to the engine forward tip of the commando frame. So the engineers were quite aware of the engine oil level.

- Joined

- Nov 10, 2012

- Messages

- 3,154

Hi and thank you.The hole is not original.

To me all this venting to relieve excessive blow-by is a sloppy method to bypass having to build a quality engine that does not leak. The primary purpose is to increase crank case volume thereby lowering pressure/vacuum cycle.

In my engines I would plug this hole and allow the oil to lube the drive side crank main bearing, chains , gears, intermediate shaft and timing side cam bush as the designers chose.

In the very early 20M3 mid series an original 20 series oil control vent hole was adjusted with an additional hole to lower the oil level due to the engine forward tip of the commando frame. So the engineers were quite aware of the engine oil level.

I agree with what you mean.

Piero

- Joined

- Dec 5, 2015

- Messages

- 70

My 64 Atlas that was owned by Bob Shontz who owned DomiRacer down in Cincinnati Ohio had moved the breather from the primary side over to the timing gear side and then hooked up a oil supply line to the old breather position and this is how the motor received its oil. He then installed needle bearing for the camshaft to ride on . I don't know where Bob got all his ideas for the mods on the bike it did have several Dunstall pieces on it so I don't know if this was Paul Dunstalls ideas or not.

Mark

Mark

- Joined

- Nov 11, 2012

- Messages

- 387

The cam oil design was used on the 1962 Norton Works Domiracer.I don't know where Bob got all his ideas for the mods on the bike it did have several Dunstall pieces on it so I don't know if this was Paul Dunstalls ideas or not.

Mark

- Joined

- May 28, 2003

- Messages

- 2,590

The cam oil design was used on the 1962 Norton Works Domiracer.

Most know Dunstall scored the norton factory race shop inventory buy out when they closed. It is quite likely that Dunstall copied the race shop design and brought it forward to the later NHT commando 20M3 And 20M3S also. The Dunstall R2 cam in my cam profiles web page was borrowed from a club friend's blown up 810 engine. I have not seen that mod on 200K and up engines which are thin cam bearing engines.

To profile that cam I had to make bushings to mimic the needle bearings, and saw the drilled oiler holes on the leading edge of the lobe ramps.

- Joined

- Apr 20, 2011

- Messages

- 5,773

Look up 500 Norton Domiracer, there is some information on the needle roller bearing for camshaft with direct oil feed to l h side.My 64 Atlas that was owned by Bob Shontz who owned DomiRacer down in Cincinnati Ohio had moved the breather from the primary side over to the timing gear side and then hooked up a oil supply line to the old breather position and this is how the motor received its oil. He then installed needle bearing for the camshaft to ride on . I don't know where Bob got all his ideas for the mods on the bike it did have several Dunstall pieces on it so I don't know if this was Paul Dunstalls ideas or not.

Mark

guest76

Guest

- Joined

- Nov 5, 2012

- Messages

- 1,034

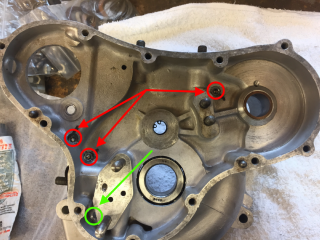

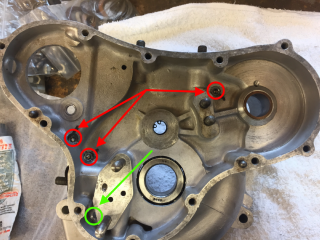

I treat the pre-commando engine exactly the same way as the Commando one, and block up the holes between timing side and crankside (circled in red).

Additionally, I drill a new hole lower down (circled in green), and block up the original oil drain hole.

I like the lower hole, as I see noticeably less air in the oil that gets returned to the tank - I assume it is getting whipped up far less.

I have done two 650ss Dommies like this, and am very pleased with the results.

The first, I fitted one of Comstock's sump plug reed breathers, and for comparison the second engine I fitted a reed valve on the back of the crankcase (same position as the Combat)

I remove the rotary breather plate and spring that engage with the end of the camshaft, and block up the breather hole in the crankcase.

The result is a leak free bike, whose breathing is excellent.

The performance of these reed breathers are noticeably better than our MK3 Commando - to this we have fitted one of Comstock's sump plug reed breathers and have blocked up the factory standard breather union on the back of the timing side 'ear'.

However, the standard holes between timing side and crankside are still there.

Increasing the size of the cavity under the piston acts as a damper (or cushion) which lessens the effectiveness of the reed.

In fact, I would assume that at high rpm it doesn't resonate/pulse like it is designed to do, rendering it effective only as a pressure relief valve at higher revs.

Don't get me wrong, it is still effective (and an absolute godsend for clearing a wet-sumped crankcase) - it is just not as efficient as the setup where the holes to the timing side are blocked.

Additionally, I drill a new hole lower down (circled in green), and block up the original oil drain hole.

I like the lower hole, as I see noticeably less air in the oil that gets returned to the tank - I assume it is getting whipped up far less.

I have done two 650ss Dommies like this, and am very pleased with the results.

The first, I fitted one of Comstock's sump plug reed breathers, and for comparison the second engine I fitted a reed valve on the back of the crankcase (same position as the Combat)

I remove the rotary breather plate and spring that engage with the end of the camshaft, and block up the breather hole in the crankcase.

The result is a leak free bike, whose breathing is excellent.

The performance of these reed breathers are noticeably better than our MK3 Commando - to this we have fitted one of Comstock's sump plug reed breathers and have blocked up the factory standard breather union on the back of the timing side 'ear'.

However, the standard holes between timing side and crankside are still there.

Increasing the size of the cavity under the piston acts as a damper (or cushion) which lessens the effectiveness of the reed.

In fact, I would assume that at high rpm it doesn't resonate/pulse like it is designed to do, rendering it effective only as a pressure relief valve at higher revs.

Don't get me wrong, it is still effective (and an absolute godsend for clearing a wet-sumped crankcase) - it is just not as efficient as the setup where the holes to the timing side are blocked.